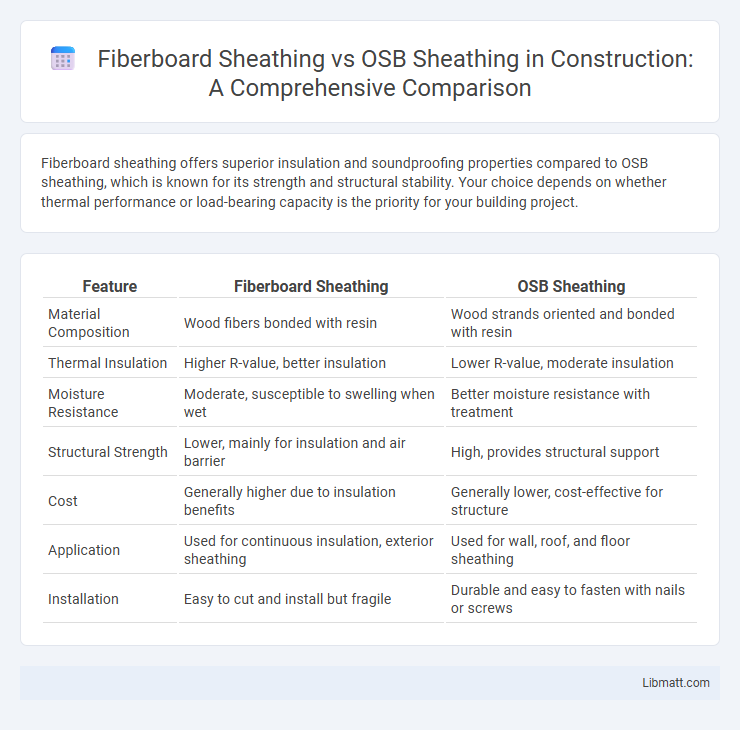

Fiberboard sheathing offers superior insulation and soundproofing properties compared to OSB sheathing, which is known for its strength and structural stability. Your choice depends on whether thermal performance or load-bearing capacity is the priority for your building project.

Table of Comparison

| Feature | Fiberboard Sheathing | OSB Sheathing |

|---|---|---|

| Material Composition | Wood fibers bonded with resin | Wood strands oriented and bonded with resin |

| Thermal Insulation | Higher R-value, better insulation | Lower R-value, moderate insulation |

| Moisture Resistance | Moderate, susceptible to swelling when wet | Better moisture resistance with treatment |

| Structural Strength | Lower, mainly for insulation and air barrier | High, provides structural support |

| Cost | Generally higher due to insulation benefits | Generally lower, cost-effective for structure |

| Application | Used for continuous insulation, exterior sheathing | Used for wall, roof, and floor sheathing |

| Installation | Easy to cut and install but fragile | Durable and easy to fasten with nails or screws |

Introduction to Fiberboard and OSB Sheathing

Fiberboard sheathing consists of engineered wood fibers compressed into panels, offering superior thermal insulation and soundproofing qualities compared to OSB sheathing, which is made of wood strands bonded with adhesives for durability and moisture resistance. OSB sheathing is widely used in structural applications due to its strength and cost-effectiveness, whereas fiberboard is preferred for enhancing wall assemblies' energy efficiency. Understanding the differences in composition and performance can help you select the ideal sheathing for your building project's specific needs.

Composition and Manufacturing Process

Fiberboard sheathing is made from wood fibers bonded with resins under heat and pressure, resulting in a dense, uniform panel that offers excellent insulation and moisture resistance. Oriented Strand Board (OSB) consists of thin wood strands oriented in layers, compressed with adhesives to create a robust, structural panel favored for load-bearing applications. The manufacturing process of fiberboard involves refining wood fibers and compressing them into sheets, while OSB production aligns wood strands strategically to enhance strength and dimensional stability.

Structural Strength and Durability

Fiberboard sheathing offers excellent insulation but generally provides lower structural strength compared to OSB sheathing, which is engineered for high load-bearing capacity and impact resistance. OSB sheathing enhances wall stability and durability under various environmental stresses, making it a preferred choice for structural applications. You should select OSB sheathing when structural integrity and long-term performance are critical to your building project's success.

Moisture Resistance and Weather Performance

Fiberboard sheathing offers superior moisture resistance due to its density and ability to absorb and release moisture without deteriorating, making it ideal for preventing mold growth and enhancing indoor air quality. OSB sheathing, while structurally strong and cost-effective, is more susceptible to swelling and delamination when exposed to prolonged moisture, which can compromise its weather performance. Proper installation and protective barriers are essential for both materials to maintain durability and effectiveness in varying weather conditions.

Insulation and Energy Efficiency

Fiberboard sheathing offers superior insulation properties due to its higher R-value compared to OSB sheathing, making it more effective at reducing heat transfer and improving overall energy efficiency in buildings. OSB sheathing provides structural strength but typically has lower thermal resistance, which may result in higher energy consumption for heating and cooling. Choosing fiberboard sheathing for Your walls can enhance thermal performance, contributing to lower utility bills and improved indoor comfort.

Cost Comparison: Fiberboard vs OSB

Fiberboard sheathing typically costs more per sheet than OSB, with fiberboard prices averaging around $25 to $40, while OSB generally ranges from $15 to $25. Despite the higher initial cost, fiberboard offers superior insulation and moisture resistance, potentially reducing long-term energy expenses. OSB remains popular for budget-conscious projects due to its affordability and structural strength, making it a cost-effective choice for many construction needs.

Installation: Tools and Techniques

Fiberboard sheathing requires precision cutting tools such as utility knives and straight edges for clean edges, while OSB sheathing is typically cut with circular saws or handsaws due to its density and thickness. Installing fiberboard often involves adhesive application and careful nailing to avoid damage, whereas OSB installation relies on robust fasteners like screws or nails driven into studs for structural support. Your choice between the two impacts the toolset and technique needed, influencing both installation time and durability.

Environmental Impact and Sustainability

Fiberboard sheathing is typically made from recycled wood fibers and agricultural residues, making it a more sustainable option with lower embodied energy compared to OSB sheathing, which relies on wood strands bonded with adhesives. OSB production generates higher waste and often involves formaldehyde-based resins, impacting indoor air quality and increasing environmental concerns. Fiberboard sheathing also offers better recyclability and biodegradability, aligning with green building standards and reducing long-term landfill contributions.

Common Applications in Construction

Fiberboard sheathing is commonly used in residential and light commercial construction for insulation and as a vapor barrier due to its excellent thermal properties and moisture resistance. OSB (Oriented Strand Board) sheathing is preferred for structural walls, roofs, and subfloors, offering superior strength, impact resistance, and load-bearing capacity in framing systems. Both materials contribute to energy efficiency and durability but are selected based on specific project requirements such as weather exposure and structural support.

Choosing the Right Sheathing for Your Project

Fiberboard sheathing offers superior insulation and soundproofing, making it ideal for projects prioritizing energy efficiency and noise reduction. OSB sheathing provides exceptional structural strength and moisture resistance, suitable for load-bearing walls and exterior applications. Understanding your project's specific needs, such as thermal performance or structural support, helps you select the right sheathing to enhance durability and comfort.

Fiberboard sheathing vs OSB sheathing Infographic

libmatt.com

libmatt.com