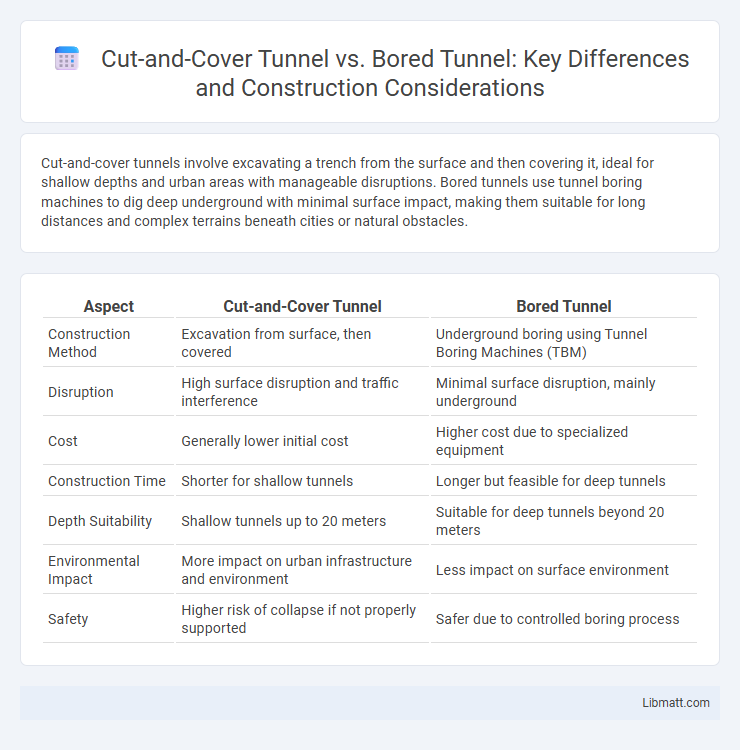

Cut-and-cover tunnels involve excavating a trench from the surface and then covering it, ideal for shallow depths and urban areas with manageable disruptions. Bored tunnels use tunnel boring machines to dig deep underground with minimal surface impact, making them suitable for long distances and complex terrains beneath cities or natural obstacles.

Table of Comparison

| Aspect | Cut-and-Cover Tunnel | Bored Tunnel |

|---|---|---|

| Construction Method | Excavation from surface, then covered | Underground boring using Tunnel Boring Machines (TBM) |

| Disruption | High surface disruption and traffic interference | Minimal surface disruption, mainly underground |

| Cost | Generally lower initial cost | Higher cost due to specialized equipment |

| Construction Time | Shorter for shallow tunnels | Longer but feasible for deep tunnels |

| Depth Suitability | Shallow tunnels up to 20 meters | Suitable for deep tunnels beyond 20 meters |

| Environmental Impact | More impact on urban infrastructure and environment | Less impact on surface environment |

| Safety | Higher risk of collapse if not properly supported | Safer due to controlled boring process |

Introduction to Tunnel Construction Methods

Cut-and-cover tunnel construction involves excavating a trench from the surface, constructing the tunnel, and then covering it back up, making it suitable for shallow tunnels in urban settings with limited underground utility conflicts. Bored tunnels are created using tunnel boring machines (TBMs) that excavate deep underground, minimizing surface disruption and allowing for longer tunnel lengths under varied geological conditions. Selection between cut-and-cover and bored tunnel methods depends on factors such as depth, soil stability, environmental impact, and project timelines.

Overview of Cut-and-Cover Tunnels

Cut-and-cover tunnels involve excavating a trench from the surface, constructing the tunnel structure within the trench, and then covering it back with soil, making them ideal for shallow underground projects. This method is often more cost-effective and faster for tunnels located near the surface but can cause significant surface disruption, impacting urban areas and traffic. Compared to bored tunnels, cut-and-cover tunnels are less suitable for deep or long tunnels where minimal surface interference is required.

Overview of Bored Tunnels

Bored tunnels are constructed using tunnel boring machines (TBMs), minimizing surface disruption and making them ideal for urban environments with dense infrastructure. These tunnels offer precise excavation with reduced noise, vibration, and environmental impact compared to cut-and-cover methods. Your project benefits from increased safety and faster completion times when using bored tunnels in complex geological conditions.

Key Differences Between Cut-and-Cover and Bored Tunnels

Cut-and-cover tunnels involve excavating a trench from the surface, constructing the tunnel, and then covering it, making them ideal for shallow projects with minimal depth. Bored tunnels use tunnel boring machines (TBMs) to create underground passages deep beneath the surface, reducing surface disruption and suited for longer, more complex routes. Your choice between these methods impacts construction time, cost, and environmental effects, with cut-and-cover typically being faster and less expensive for shallow tunnels, while bored tunnels offer greater safety and less surface impact.

Construction Process Comparison

Cut-and-cover tunnels involve excavating a trench from the surface, constructing the tunnel structure, and then backfilling the excavation, making it suitable for shallow depths and simpler geological conditions. Bored tunnels are created using tunnel boring machines (TBMs) that excavate through the ground underground, minimizing surface disruption and allowing for deeper tunnel alignments in complex soil or rock conditions. The construction process of cut-and-cover is generally faster and less expensive for shallow tunnels, while bored tunneling offers greater precision and safety for long, deep, and urban crossings.

Cost Implications and Budget Considerations

Cut-and-cover tunnels generally incur lower initial construction costs compared to bored tunnels due to simpler excavation techniques and reduced machinery expenses. However, cut-and-cover projects often require extensive surface disruption, leading to indirect costs such as traffic diversion and property compensation. Bored tunnels, while more expensive upfront because of specialized tunneling machines and slower progress, can minimize surface impact and reduce long-term social and environmental costs.

Environmental Impact and Sustainability

Cut-and-cover tunnels typically cause significant surface disruption, leading to habitat destruction, increased noise, dust pollution, and traffic delays, impacting local ecosystems and urban environments. Bored tunnels minimize surface disturbances, preserving existing landscapes and reducing greenhouse gas emissions associated with extensive excavation and restoration processes. Sustainable tunnel construction favors bored methods where feasible to protect biodiversity and promote long-term environmental resilience.

Urban vs. Rural Application Scenarios

Cut-and-cover tunnels are often preferred in urban areas due to lower costs and simpler construction processes, especially where surface disruption is manageable. Bored tunnels suit rural or densely populated urban scenarios requiring minimal surface disturbance and preserving existing infrastructure. Your project's location and impact tolerance largely determine the optimal tunneling method.

Safety and Maintenance Factors

Cut-and-cover tunnels offer easier access for inspections and repairs, leading to simplified maintenance and quicker response to safety issues. Bored tunnels, constructed deep underground, provide enhanced structural stability and reduced surface disruption, resulting in lower immediate risk of collapse but more complex inspection procedures. Your choice between these methods should consider long-term safety monitoring capabilities and maintenance accessibility based on project requirements.

Choosing the Right Tunnel Method: Decision Criteria

Selecting the appropriate tunnel method depends on factors such as ground conditions, urban density, project budget, and environmental impact. Cut-and-cover tunnels are suitable for shallow depths with minimal surface disruption, while bored tunnels excel in deep excavation and minimizing surface disturbance. Your project timeline and site accessibility also play crucial roles in determining whether cut-and-cover or bored tunneling aligns best with your construction goals.

Cut-and-cover tunnel vs bored tunnel Infographic

libmatt.com

libmatt.com