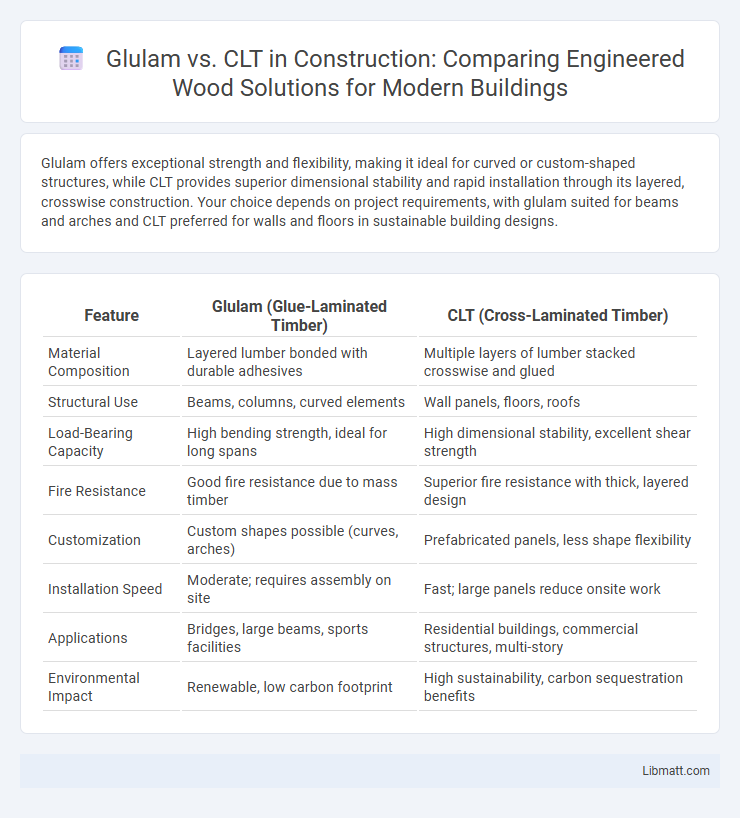

Glulam offers exceptional strength and flexibility, making it ideal for curved or custom-shaped structures, while CLT provides superior dimensional stability and rapid installation through its layered, crosswise construction. Your choice depends on project requirements, with glulam suited for beams and arches and CLT preferred for walls and floors in sustainable building designs.

Table of Comparison

| Feature | Glulam (Glue-Laminated Timber) | CLT (Cross-Laminated Timber) |

|---|---|---|

| Material Composition | Layered lumber bonded with durable adhesives | Multiple layers of lumber stacked crosswise and glued |

| Structural Use | Beams, columns, curved elements | Wall panels, floors, roofs |

| Load-Bearing Capacity | High bending strength, ideal for long spans | High dimensional stability, excellent shear strength |

| Fire Resistance | Good fire resistance due to mass timber | Superior fire resistance with thick, layered design |

| Customization | Custom shapes possible (curves, arches) | Prefabricated panels, less shape flexibility |

| Installation Speed | Moderate; requires assembly on site | Fast; large panels reduce onsite work |

| Applications | Bridges, large beams, sports facilities | Residential buildings, commercial structures, multi-story |

| Environmental Impact | Renewable, low carbon footprint | High sustainability, carbon sequestration benefits |

Introduction to Glulam and CLT

Glulam (glued laminated timber) is an engineered wood product composed of multiple layers of lumber bonded together with durable, moisture-resistant adhesives, offering high strength and design flexibility. CLT (cross-laminated timber) consists of several layers of lumber stacked crosswise and glued to form large, solid panels ideal for walls, floors, and roofs, providing excellent structural stability and fire resistance. You can choose between Glulam and CLT based on your project's specific architectural and load-bearing requirements, as both materials are sustainable alternatives to traditional construction methods.

Manufacturing Processes of Glulam vs CLT

Glulam is manufactured by bonding multiple layers of dimensional lumber with durable adhesives, aligning the grain parallel for enhanced strength, while CLT involves stacking and gluing perpendicular layers of lumber boards to form solid panels. The glue curing process and pressing methods differ, with glulam panels requiring long presses to ensure structural integrity and CLT panels often using hydraulic presses for precise layer adhesion. Understanding these manufacturing distinctions helps you select the right engineered wood product tailored to your project's structural and aesthetic requirements.

Structural Performance Comparison

Glulam offers superior flexural strength due to its laminated veneer composition, making it ideal for beams and columns requiring high load-bearing capacity. CLT provides excellent dimensional stability and rigidity through its multi-layered crosswise lamination, enhancing shear resistance and lateral load distribution in floor and wall panels. Both materials exhibit impressive structural performance, with Glulam excelling in bending applications and CLT in panelized structural systems, optimizing building efficiency and seismic resilience.

Applications and Use Cases

Glulam excels in structural components such as beams, columns, and arches for bridges, commercial buildings, and large-span roofs due to its high strength-to-weight ratio and customizability. CLT is widely used for walls, floors, and roofs in residential, multi-story, and modular buildings, offering excellent dimensional stability and rapid construction capabilities with prefabricated panels. Both materials support sustainable construction practices but serve distinct architectural and engineering needs based on load requirements and assembly methods.

Environmental Impact and Sustainability

Glulam and CLT both offer sustainable alternatives to traditional construction materials, with Glulam being made from smaller wood pieces glued together, allowing efficient use of timber and reducing waste. CLT's layered cross-grain structure enhances structural strength and stability while sourcing wood from responsibly managed forests supports carbon sequestration and reduces the carbon footprint. Both materials contribute significantly to lowering embodied energy in buildings, but CLT's prefabricated panels can improve construction speed and precision, minimizing on-site waste.

Fire Resistance and Safety

Glulam (glued laminated timber) exhibits superior fire resistance due to its thick solid wood layers that char slowly, maintaining structural integrity during exposure to fire. CLT (cross-laminated timber), while engineered with cross layers for strength, has a similar charring rate but may require additional fire protection measures such as intumescent coatings or sprinkler systems to meet fire safety standards. Both materials comply with international building codes, but glulam's inherent thickness often provides enhanced passive fire resistance in structural applications.

Cost Analysis and Affordability

Glulam offers a lower upfront cost compared to Cross-laminated timber (CLT) due to simpler manufacturing processes and widespread availability of raw materials. However, CLT provides greater structural efficiency and faster on-site assembly, potentially reducing overall project costs in large-scale or complex buildings. Affordability depends on project size, complexity, and regional material availability, with Glulam favoring budget-conscious projects and CLT suited for high-performance, cost-optimized construction.

Design Flexibility and Aesthetic Qualities

Glulam offers exceptional design flexibility due to its ability to be curved and customized in various shapes, making it ideal for complex architectural forms and aesthetic appeal. CLT provides strong, flat panels that enable efficient large-scale construction with a modern, minimalist aesthetic but limited curvature options. Both materials enhance natural wood appearance, but glulam's versatility allows more creative and visually dynamic structural elements.

Installation and Construction Speed

Glulam offers faster installation on site due to its simpler, single-direction lamination, allowing for quicker assembly with standard tools and fewer connection points. CLT panels, while larger and heavier, provide rapid construction by covering large areas in one piece, reducing the number of joints and the need for interior framing. Both materials contribute to accelerated build times, but Glulam is generally preferred for projects requiring flexible design and quicker on-site installation efficiency.

Choosing the Right Timber Product

Choosing the right timber product depends on project requirements such as structural support, design flexibility, and environmental impact. Glulam offers superior strength for long spans and curved shapes, making it ideal for beams and arches, while CLT provides excellent dimensional stability and is preferred for wall, floor, and roof panels due to its cross-laminated layers. Consider factors like load-bearing capacity, fabrication complexity, and sustainability certifications when deciding between Glulam and CLT.

Glulam vs CLT (Cross-laminated timber) Infographic

libmatt.com

libmatt.com