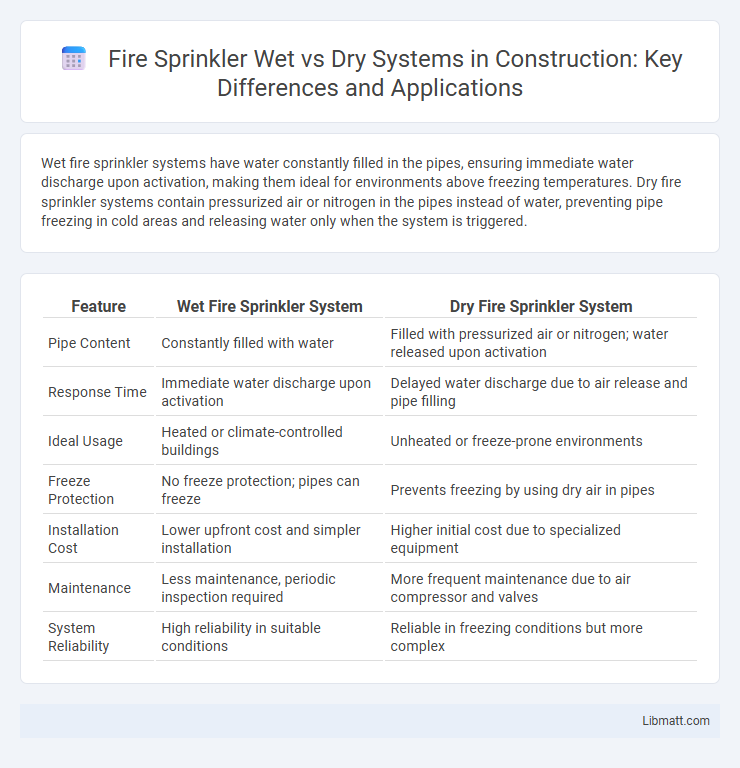

Wet fire sprinkler systems have water constantly filled in the pipes, ensuring immediate water discharge upon activation, making them ideal for environments above freezing temperatures. Dry fire sprinkler systems contain pressurized air or nitrogen in the pipes instead of water, preventing pipe freezing in cold areas and releasing water only when the system is triggered.

Table of Comparison

| Feature | Wet Fire Sprinkler System | Dry Fire Sprinkler System |

|---|---|---|

| Pipe Content | Constantly filled with water | Filled with pressurized air or nitrogen; water released upon activation |

| Response Time | Immediate water discharge upon activation | Delayed water discharge due to air release and pipe filling |

| Ideal Usage | Heated or climate-controlled buildings | Unheated or freeze-prone environments |

| Freeze Protection | No freeze protection; pipes can freeze | Prevents freezing by using dry air in pipes |

| Installation Cost | Lower upfront cost and simpler installation | Higher initial cost due to specialized equipment |

| Maintenance | Less maintenance, periodic inspection required | More frequent maintenance due to air compressor and valves |

| System Reliability | High reliability in suitable conditions | Reliable in freezing conditions but more complex |

Introduction to Fire Sprinkler Systems

Fire sprinkler systems are essential components of fire protection strategies, designed to automatically suppress or control fires in buildings. Wet systems maintain water in the pipes at all times, providing immediate discharge upon activation, making them ideal for environments free from freezing temperatures. Dry systems fill pipes with pressurized air or nitrogen, releasing water only when triggered, which prevents pipe freezing in colder climates or unheated areas.

How Wet Sprinkler Systems Work

Wet sprinkler systems maintain pipes constantly filled with pressurized water, enabling immediate water discharge upon sprinkler activation. Each sprinkler head contains a heat-sensitive element that triggers water release when exposed to high temperatures from a fire. This continuous water presence ensures rapid fire suppression and minimizes damage.

How Dry Sprinkler Systems Operate

Dry sprinkler systems operate by using pressurized air or nitrogen to hold a closed valve, preventing water from entering the pipes until a fire triggers the system. When heat from a fire reaches the sprinkler head, it activates and releases the air pressure, allowing water to flow through the pipes and extinguish the flames. Your choice between dry and wet systems depends on environmental conditions, such as protection against freezing temperatures.

Key Differences Between Wet and Dry Systems

Wet fire sprinkler systems contain water in the pipes at all times, ensuring immediate discharge upon activation, which is ideal for environments maintained above freezing temperatures. Dry fire sprinkler systems use pressurized air or nitrogen in the pipes, releasing water only when the system is triggered, making them suitable for unheated or cold spaces to prevent pipe freezing. The choice between these systems depends on temperature conditions, installation environment, and the specific fire protection needs of the building.

Advantages of Wet Sprinkler Systems

Wet sprinkler systems offer rapid fire suppression since water is constantly present in the pipes, enabling immediate discharge upon sprinkler activation. Their design reduces maintenance costs due to fewer components and lower risk of system freezing compared to dry systems. Wet systems are ideal for environments without freezing hazards, providing reliable performance and consistent protection against fire damage.

Benefits and Limitations of Dry Sprinkler Systems

Dry sprinkler systems offer distinct advantages in environments prone to freezing temperatures, as their pipes are filled with pressurized air or nitrogen instead of water, preventing pipe bursts caused by frozen water. Their primary limitation is slower response time during activation because air must first be released before water is dispensed, potentially delaying fire suppression. Maintenance and inspection requirements are more rigorous due to the complexity of air pressure monitoring and potential for corrosion in the dry system components.

Ideal Applications for Wet Sprinkler Systems

Wet sprinkler systems are ideal for interior environments with temperatures consistently above freezing, such as offices, residential buildings, and commercial spaces. They provide immediate water discharge upon sprinkler activation, ensuring rapid fire suppression in areas with reliable, year-round heat. Your choice of a wet system maximizes efficiency where pipe freezing is not a concern, offering low maintenance and quick response times.

Best Uses for Dry Sprinkler Systems

Dry sprinkler systems are best used in environments where freezing temperatures could damage pipes, such as unheated warehouses, parking garages, and building exterior areas. By keeping water out of the pipes until a sprinkler is activated, they prevent pipe burst risks in cold climates. Your facility benefits from enhanced protection against fire without the worry of water damage from frozen or broken piping.

Maintenance and Cost Considerations

Wet fire sprinkler systems generally have lower maintenance requirements and costs since they contain water at all times, enabling quicker inspections and fewer parts prone to wear. Dry systems require more frequent maintenance due to the presence of pressurized air or nitrogen, which can lead to valve failures and corrosion from condensation, resulting in higher operational expenses. Your choice between wet and dry systems should consider these maintenance demands and long-term cost implications based on the environment of installation.

Choosing the Right Sprinkler System for Your Building

Choosing the right fire sprinkler system depends on the building's temperature conditions and occupancy risks; wet systems, filled with water, are ideal for environments above 40degF, providing quick response to fires. Dry systems use pressurized air or nitrogen to prevent freezing in unheated or cold areas, making them suitable for warehouses, parking garages, and loading docks. Understanding local fire codes, maintenance requirements, and potential freeze hazards ensures optimal protection and compliance with NFPA standards.

Fire sprinkler wet vs dry system Infographic

libmatt.com

libmatt.com