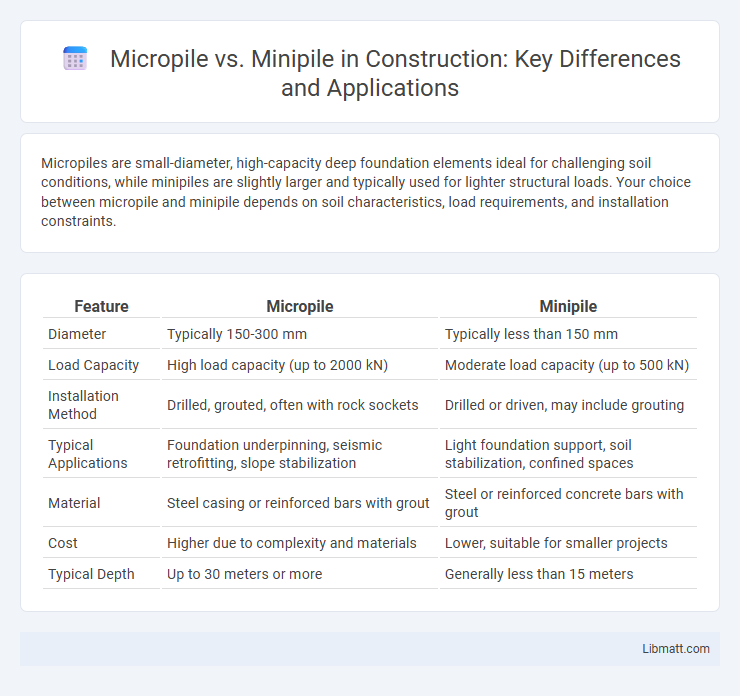

Micropiles are small-diameter, high-capacity deep foundation elements ideal for challenging soil conditions, while minipiles are slightly larger and typically used for lighter structural loads. Your choice between micropile and minipile depends on soil characteristics, load requirements, and installation constraints.

Table of Comparison

| Feature | Micropile | Minipile |

|---|---|---|

| Diameter | Typically 150-300 mm | Typically less than 150 mm |

| Load Capacity | High load capacity (up to 2000 kN) | Moderate load capacity (up to 500 kN) |

| Installation Method | Drilled, grouted, often with rock sockets | Drilled or driven, may include grouting |

| Typical Applications | Foundation underpinning, seismic retrofitting, slope stabilization | Light foundation support, soil stabilization, confined spaces |

| Material | Steel casing or reinforced bars with grout | Steel or reinforced concrete bars with grout |

| Cost | Higher due to complexity and materials | Lower, suitable for smaller projects |

| Typical Depth | Up to 30 meters or more | Generally less than 15 meters |

Introduction to Micropiles and Minipiles

Micropiles and minipiles are specialized deep foundation solutions designed to support structures with limited access or challenging soil conditions. Micropiles typically have diameters less than 300 mm and are installed using high-pressure grouting and steel reinforcement, providing high load capacity and adaptability for seismic or retrofit applications. Your choice between micropiles and minipiles depends on project-specific factors such as load requirements, soil type, and installation constraints.

Definition and Classification

Micropiles and minipiles are both types of deep foundation elements used to transfer loads to deeper, more stable soil layers or rock. Micropiles are small-diameter, high-capacity drilled and grouted piles typically less than 300 mm in diameter, classified by their installation method and grout type, whereas minipiles are often defined as piles with diameters ranging from 150 mm to 300 mm, focusing on load capacity and installation technique. Understanding the specific classification and definition helps optimize your foundation design by selecting the appropriate pile type according to soil conditions and structural requirements.

Key Differences Between Micropiles and Minipiles

Micropiles typically range from 5 to 12 inches in diameter and are designed to transfer structural loads through soil and rock to deeper, more stable layers, while minipiles usually measure between 3 to 6 inches in diameter and are used for lighter structural loads and foundation repairs. Micropiles are driven deep with high load capacities, often exceeding 100 tons, whereas minipiles are shallower and suited for applications requiring smaller load bearing, around 20 to 50 tons. Installation methods for micropiles often involve drilling and grouting, contrasting with minipiles that can be installed using smaller drilling rigs or driven techniques for tighter spaces and less invasive groundwork.

Materials and Construction Techniques

Micropiles typically consist of high-strength steel casing combined with grout injection, anchoring through drilled and grouted holes to transfer loads effectively in weak soil conditions. Minipiles are generally smaller in diameter, often using steel bars and smaller casings, installed via drilled or driven methods with grout to enhance load capacity and corrosion protection. Both use advanced materials such as epoxy-coated rebar or stainless steel for durability, but micropiles are favored for deeper or more complex geotechnical challenges due to their robust construction techniques and higher load-bearing capacity.

Load-Bearing Capacities

Micropiles typically support load capacities ranging from 50 to 500 kips, making them ideal for underpinning and seismic retrofitting in restricted sites. Minipiles generally carry loads between 25 to 150 kips and are suited for smaller structural foundations or soil stabilization. Understanding the specific load-bearing requirements of your project ensures the right choice between micropiles and minipiles.

Applications in Construction Projects

Micropiles and minipiles serve as essential foundation solutions in construction projects requiring deep foundation support in restricted access areas or challenging soil conditions. Micropiles, with diameters typically ranging from 150 mm to 300 mm, are favored for underpinning existing structures and seismic retrofitting due to their high load-bearing capacity and minimal vibration impact. Your choice between micropiles and minipiles depends on project scale and load requirements, with minipiles generally used for lighter loads and smaller-scale applications.

Installation Process Comparison

Micropile installation involves drilling small-diameter, high-capacity steel piles deeply into the ground using rotary or percussion drilling techniques, allowing for precise control in challenging soil conditions. Minipile installation typically uses smaller equipment for shallower depths and is faster, relying on drilling or pushing methods ideal for limited-access sites. You should consider soil type, load requirements, and site constraints when choosing between micropiles and minipiles for optimal foundation performance.

Advantages and Disadvantages

Micropiles offer superior load capacity and versatility in restricted access sites, making them ideal for underpinning and seismic retrofitting, but they tend to have higher installation costs and longer lead times compared to minipiles. Minipiles provide cost-effective solutions for lightweight structures with faster installation, yet their limited diameter can reduce load-bearing capacity and make them less suitable for heavy foundation applications. Understanding your project's specific soil conditions and load requirements will help determine whether micropiles' strength or minipiles' economy aligns better with your foundation needs.

Cost and Budget Considerations

Micropiles typically incur higher installation costs due to their use of specialized drilling equipment and materials, making them suitable for projects with a flexible budget focusing on high load capacity and limited site access. Minipiles generally offer a more cost-effective solution with lower drilling and material expenses, ideal for smaller-scale foundations or budget-sensitive projects. Your choice between micropile and minipile should balance structural requirements and financial constraints to optimize overall project cost efficiency.

Choosing Between Micropiles and Minipiles

Choosing between micropiles and minipiles depends largely on load capacity requirements and ground conditions; micropiles typically support higher loads due to their greater diameter and are suited for challenging geotechnical environments, while minipiles are smaller and more economical for lighter loads or restricted access sites. Your project's structural demands, soil composition, and installation constraints will guide the optimal selection to ensure foundation stability and cost efficiency. Accurate geotechnical analysis combined with engineering expertise is essential to determine whether micropiles or minipiles provide the best foundation solution for your needs.

Micropile vs minipile Infographic

libmatt.com

libmatt.com