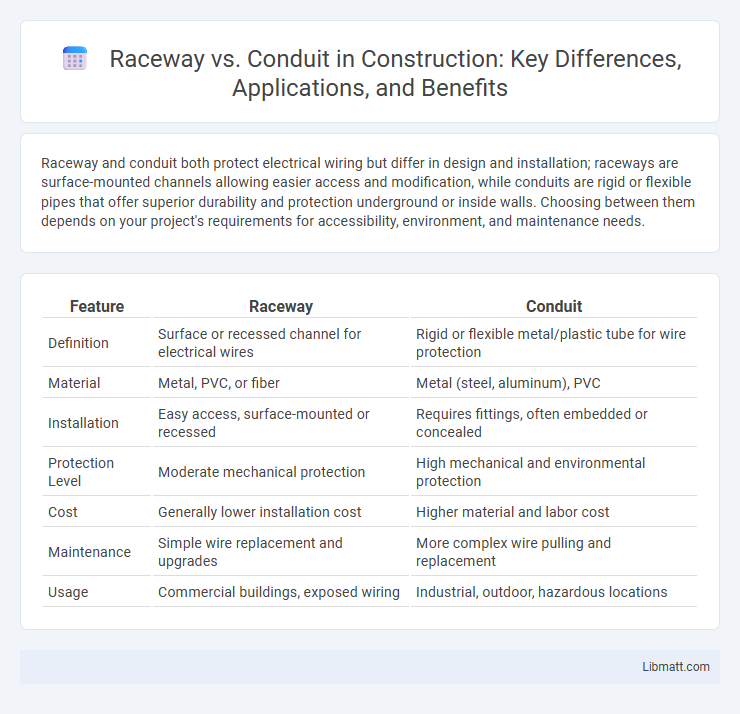

Raceway and conduit both protect electrical wiring but differ in design and installation; raceways are surface-mounted channels allowing easier access and modification, while conduits are rigid or flexible pipes that offer superior durability and protection underground or inside walls. Choosing between them depends on your project's requirements for accessibility, environment, and maintenance needs.

Table of Comparison

| Feature | Raceway | Conduit |

|---|---|---|

| Definition | Surface or recessed channel for electrical wires | Rigid or flexible metal/plastic tube for wire protection |

| Material | Metal, PVC, or fiber | Metal (steel, aluminum), PVC |

| Installation | Easy access, surface-mounted or recessed | Requires fittings, often embedded or concealed |

| Protection Level | Moderate mechanical protection | High mechanical and environmental protection |

| Cost | Generally lower installation cost | Higher material and labor cost |

| Maintenance | Simple wire replacement and upgrades | More complex wire pulling and replacement |

| Usage | Commercial buildings, exposed wiring | Industrial, outdoor, hazardous locations |

Introduction to Raceway and Conduit Systems

Raceway and conduit systems provide durable pathways for electrical wiring, ensuring safety and organization in building infrastructure. Raceway typically offers a flexible, surface-mounted solution suitable for easy access and future modifications, while conduit is a rigid or flexible metal or plastic tubing designed to protect wires from physical damage. Understanding the differences helps you select the ideal system for specific electrical installation requirements.

Defining Raceway and Its Types

Raceway refers to an enclosed channel designed to protect and route electrical wiring in buildings or industrial settings, offering a safe and organized solution compared to conduit. Common types of raceways include surface raceways, which are mounted on walls; wireways, which provide easy access for maintenance; and structural raceways integrated into building frameworks. Understanding these raceway types helps you select the best method for efficient cable management and enhanced safety in your electrical installations.

Understanding Electrical Conduit

Electrical conduit serves as a protective tubing system designed to safeguard and route electrical wiring in buildings, ensuring safety and compliance with electrical codes. Unlike raceways, which can be open or closed channels for wire management, conduits are typically rigid or flexible tubes made of metal or plastic that provide superior protection against physical damage and environmental factors. Understanding electrical conduit involves recognizing its critical role in preventing electrical hazards, facilitating maintenance, and supporting system longevity in residential, commercial, and industrial installations.

Key Differences Between Raceway and Conduit

Raceway and conduit both serve as protective pathways for electrical wiring, but raceways are typically open or surface-mounted channels that provide easier access for future modifications, whereas conduits are rigid or flexible pipes offering a higher level of protection and are often embedded within walls or underground. Raceway systems are ideal for environments requiring frequent changes or additions to wiring, while conduits excel in harsh conditions demanding strong protection against physical damage and moisture. Understanding these key differences helps you select the appropriate solution for your project's safety and maintenance needs.

Material Comparison: Raceway vs Conduit

Raceways are typically made from materials like PVC, steel, or aluminum, offering a versatile and accessible route for routing multiple cables or wires, while conduits are often comprised of rigid or flexible metallic or non-metallic substances designed for protecting and enclosing electrical wiring. Raceway materials are generally easier to install and modify, making them suitable for surface mounting and accessible wiring, whereas conduit materials provide superior durability and protection against physical damage, moisture, and corrosive environments. Your choice between raceway and conduit materials depends on the specific requirements for protection, flexibility, and installation complexity within your electrical project.

Installation Methods and Applications

Raceways offer flexible installation options, including surface mounting and easy access for wiring changes, making them ideal for commercial and industrial environments requiring frequent modifications. Conduits typically require more labor-intensive methods such as threading and burying, suitable for outdoor or underground applications demanding high protection against physical damage and environmental factors. Your choice depends on the complexity of the wiring system and the level of protection needed for specific electrical installations.

Cost Analysis: Raceway vs Conduit

Raceways generally offer lower initial installation costs compared to conduits due to easier handling and less labor-intensive mounting processes. Conduits, particularly metal types like rigid galvanized steel, provide superior protection and durability but often incur higher material and labor expenses. Long-term costs can favor raceways in environments requiring frequent modifications, while conduits reduce maintenance costs in harsh conditions due to their robust construction.

Safety and Code Compliance

Raceways and conduits both ensure electrical wiring protection, but raceways offer enhanced safety by providing a fully enclosed pathway that guards against physical damage and reduces fire hazards. Electrical codes such as the NEC (National Electrical Code) specify requirements for conduit materials and installation methods to ensure compliance with safety standards, including grounding and protection against environmental factors. Choosing the correct raceway or conduit type depends on the application, with metal conduit ensuring durability and grounding, while nonmetallic raceways offer corrosion resistance and easier installation, all while maintaining adherence to code compliance.

Pros and Cons of Raceway Systems

Raceway systems offer flexible installation, easy access for maintenance, and enhanced protection for cables in complex or exposed environments, making them ideal for commercial and industrial settings. However, they can be more expensive and visually intrusive compared to conduits, and may require more space due to their larger size. Understanding the trade-offs will help you decide if a raceway system suits your project's requirements and budget.

Pros and Cons of Conduit Systems

Conduit systems offer superior protection for electrical wiring against physical damage, moisture, and chemicals, making them ideal for harsh environments and outdoor installations. They provide excellent organization and allow for easy upgrades or modifications by enabling wires to be pulled through existing conduits without demolition. However, conduit installation can be labor-intensive and expensive compared to raceway systems, requiring precise bending and fittings, which may increase overall project costs.

Raceway vs conduit Infographic

libmatt.com

libmatt.com