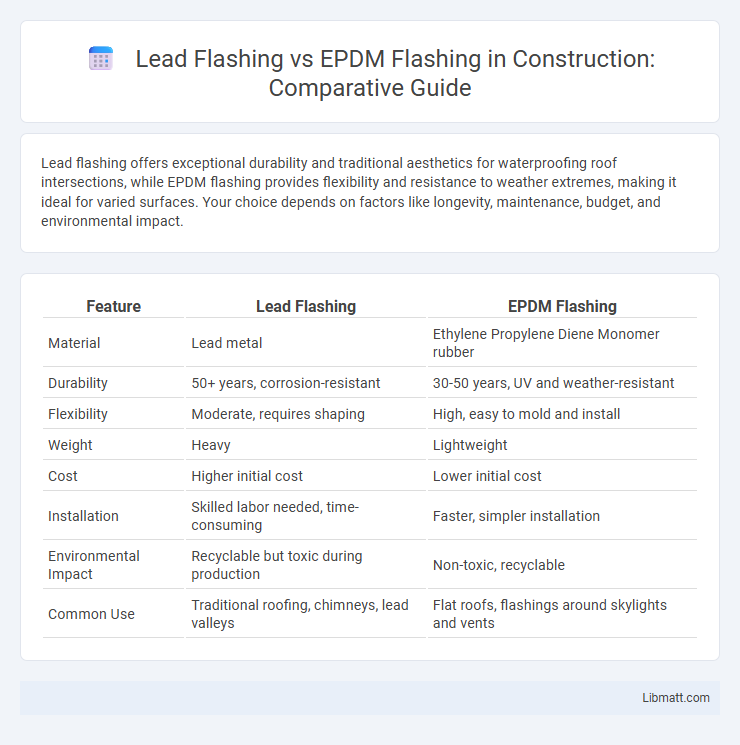

Lead flashing offers exceptional durability and traditional aesthetics for waterproofing roof intersections, while EPDM flashing provides flexibility and resistance to weather extremes, making it ideal for varied surfaces. Your choice depends on factors like longevity, maintenance, budget, and environmental impact.

Table of Comparison

| Feature | Lead Flashing | EPDM Flashing |

|---|---|---|

| Material | Lead metal | Ethylene Propylene Diene Monomer rubber |

| Durability | 50+ years, corrosion-resistant | 30-50 years, UV and weather-resistant |

| Flexibility | Moderate, requires shaping | High, easy to mold and install |

| Weight | Heavy | Lightweight |

| Cost | Higher initial cost | Lower initial cost |

| Installation | Skilled labor needed, time-consuming | Faster, simpler installation |

| Environmental Impact | Recyclable but toxic during production | Non-toxic, recyclable |

| Common Use | Traditional roofing, chimneys, lead valleys | Flat roofs, flashings around skylights and vents |

Introduction to Roof Flashing Solutions

Lead flashing offers exceptional durability and malleability, making it ideal for complex roof joints and historic restorations. EPDM flashing, a synthetic rubber material, provides excellent weather resistance and flexibility, suitable for modern flat or low-slope roofs. Both materials serve critical roles in preventing water infiltration, ensuring the longevity of roofing systems.

What is Lead Flashing?

Lead flashing is a traditional roofing material composed of malleable and durable lead sheets used to waterproof joints and prevent water penetration in buildings. Its high corrosion resistance and flexibility make it ideal for sealing around chimneys, skylights, and roof intersections. Compared to modern alternatives like EPDM flashing, lead flashing offers longevity but requires skilled installation and is less environmentally friendly.

What is EPDM Flashing?

EPDM flashing is a durable, synthetic rubber material used to seal roof joints and prevent water penetration, offering flexibility and resistance to UV rays, extreme weather, and temperature fluctuations. Unlike traditional lead flashing, EPDM flashing provides easier installation with fewer environmental concerns and longer-lasting weatherproofing performance. Your roofing system benefits from EPDM flashing's superior elasticity and compatibility with various surfaces, reducing the risk of leaks and maintenance needs.

Material Properties Comparison

Lead flashing offers exceptional durability, malleability, and corrosion resistance, making it ideal for complex roof joints and long-lasting weatherproofing. EPDM flashing, made from synthetic rubber, provides excellent flexibility, UV resistance, and ease of installation, especially suited for irregular roof shapes and expansions. Your choice depends on whether you prioritize traditional robustness with lead or modern adaptability with EPDM.

Installation Process: Lead vs EPDM

Lead flashing installation requires skilled craftsmen who carefully cut and shape the metal to ensure weather-tight seals around roof joints, using techniques like folding and soldering. EPDM flashing, made from flexible synthetic rubber, offers easier and quicker installation with adhesive backing or mechanically fastened methods, allowing for seamless adaptation to complex roof shapes. Choosing EPDM flashing can simplify your roofing project due to its lightweight, durable, and user-friendly installation process compared to the labor-intensive lead flashing.

Durability and Longevity

Lead flashing offers exceptional durability with a lifespan often exceeding 100 years due to its malleability and resistance to corrosion. EPDM flashing typically lasts between 25 to 30 years, benefiting from flexibility and resistance to UV rays and weathering but may degrade faster under extreme conditions. Choosing between lead and EPDM flashing depends on balancing long-term durability requirements with installation factors and environmental exposure.

Environmental Impact and Sustainability

Lead flashing poses significant environmental concerns due to its toxicity and potential to contaminate soil and water during production, installation, and disposal. EPDM flashing, made from synthetic rubber, offers a more sustainable alternative with lower carbon footprint, recyclability, and resistance to weathering, reducing maintenance and replacement frequency. Choosing EPDM enhances green building practices by minimizing hazardous waste and supporting long-term environmental health.

Cost Comparison and Value

Lead flashing generally incurs higher initial costs due to its material price and skilled labor requirements, but offers exceptional durability and weather resistance that may reduce long-term maintenance expenses. EPDM flashing presents a more affordable upfront investment with easier installation, yet may require replacement sooner under harsh conditions, potentially increasing lifecycle costs. Evaluating project specifics such as budget constraints and expected lifespan helps determine the best value between lead and EPDM flashing solutions.

Common Applications and Suitability

Lead flashing is commonly used for traditional roofing projects and chimneys due to its durability and malleability, making it suitable for complex roof joints and historic buildings. EPDM flashing, a synthetic rubber material, excels in modern flat roofing systems and areas with high UV exposure, providing excellent water resistance and flexibility. Your choice between lead and EPDM flashing should consider the roof type, environmental conditions, and long-term maintenance requirements.

Choosing the Right Flashing for Your Project

Lead flashing offers exceptional durability and malleability, making it ideal for complex roof joints and long-term weather resistance, while EPDM flashing provides flexibility, UV resistance, and ease of installation, especially suited for flat or low-slope roofs. Your choice depends on factors such as roof type, environmental conditions, and project budget, with lead excelling in longevity and EPDM providing cost-effective, quick application. Prioritize material compatibility and maintenance requirements to ensure a secure, leak-proof seal tailored to your roofing needs.

Lead flashing vs EPDM flashing Infographic

libmatt.com

libmatt.com