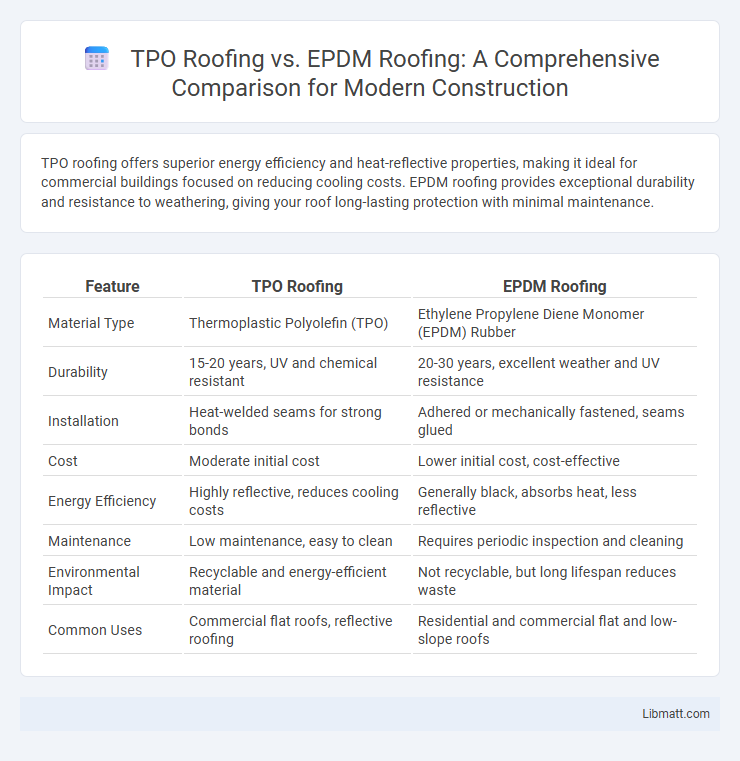

TPO roofing offers superior energy efficiency and heat-reflective properties, making it ideal for commercial buildings focused on reducing cooling costs. EPDM roofing provides exceptional durability and resistance to weathering, giving your roof long-lasting protection with minimal maintenance.

Table of Comparison

| Feature | TPO Roofing | EPDM Roofing |

|---|---|---|

| Material Type | Thermoplastic Polyolefin (TPO) | Ethylene Propylene Diene Monomer (EPDM) Rubber |

| Durability | 15-20 years, UV and chemical resistant | 20-30 years, excellent weather and UV resistance |

| Installation | Heat-welded seams for strong bonds | Adhered or mechanically fastened, seams glued |

| Cost | Moderate initial cost | Lower initial cost, cost-effective |

| Energy Efficiency | Highly reflective, reduces cooling costs | Generally black, absorbs heat, less reflective |

| Maintenance | Low maintenance, easy to clean | Requires periodic inspection and cleaning |

| Environmental Impact | Recyclable and energy-efficient material | Not recyclable, but long lifespan reduces waste |

| Common Uses | Commercial flat roofs, reflective roofing | Residential and commercial flat and low-slope roofs |

Introduction to TPO and EPDM Roofing

TPO roofing consists of a single-ply membrane made from thermoplastic polyolefin, favored for its reflective properties and energy efficiency in commercial roofing applications. EPDM roofing features a durable synthetic rubber membrane known for exceptional weather resistance and flexibility, particularly effective in extreme temperature variations. Both materials offer cost-effective solutions with distinct performance benefits tailored to different roofing requirements.

Material Composition and Technology

TPO roofing consists of a single-ply membrane made from thermoplastic polyolefin, blending polypropylene and ethylene-propylene rubber, known for its heat-reflective properties and resistance to UV rays and chemical exposure. EPDM roofing features a synthetic rubber membrane composed primarily of ethylene and propylene monomers, offering exceptional flexibility, weather resistance, and durability in extreme temperatures. The advanced welding technology used in TPO roofing creates strong seams through heat fusion, while EPDM relies on adhesive or mechanical fasteners, impacting installation methods and long-term performance.

Installation Process Comparison

TPO roofing offers a relatively quick installation process through heat welding seams, resulting in strong, watertight bonds that reduce labor time and potential leak points. EPDM roofing requires adhesive or mechanical fasteners to secure seams, often leading to longer installation times and increased sensitivity to weather conditions during application. Your choice may depend on the preferred installation speed and durability needs specific to your roofing project.

Energy Efficiency and Reflectivity

TPO roofing offers superior energy efficiency due to its high reflectivity, which significantly reduces heat absorption and lowers cooling costs in commercial buildings. EPDM roofing generally has lower reflectivity, absorbing more heat and potentially increasing energy expenses during warmer months. Choosing TPO roofing can enhance your building's overall energy performance by reflecting more sunlight and maintaining cooler interior temperatures.

Durability and Longevity

TPO roofing offers excellent durability against UV rays, chemical exposure, and punctures, typically lasting 15-20 years with proper maintenance. EPDM roofing is renowned for its longevity, often exceeding 25-30 years due to high resistance to weathering and temperature extremes. Your choice between TPO and EPDM should consider the expected lifespan and environmental conditions of your roofing project.

Cost Factors and Budget Considerations

TPO roofing typically costs between $5.50 and $9.00 per square foot, making it a more budget-friendly option compared to EPDM roofing, which ranges from $6.00 to $12.00 per square foot. Installation expenses for TPO can be higher due to specialized welding techniques, while EPDM's simpler adhesive or mechanical fastening process often reduces labor costs. Your choice should weigh upfront material prices against long-term durability and maintenance expenses to optimize overall roofing investment.

Maintenance Requirements

TPO roofing typically requires regular inspections and cleaning to prevent membrane degradation from UV exposure and debris accumulation, ensuring long-term performance. EPDM roofing demands less frequent maintenance due to its durable synthetic rubber composition, though periodic checks for punctures and seam integrity remain essential. Both roofing systems benefit from proactive documentation of inspections and swift repairs to maximize lifespan and efficiency.

Environmental Impact and Sustainability

TPO roofing offers a sustainable option with its energy-efficient reflective surface that reduces cooling costs and lowers urban heat island effects, while being recyclable at the end of its lifespan. EPDM roofing is valued for its durability and long service life, which minimizes material waste, and its potential for recycling, though it generally has a higher environmental footprint due to its petroleum-based composition. Both materials contribute to sustainability differently, with TPO emphasizing energy savings and EPDM focusing on longevity and recyclability.

Common Applications and Suitability

TPO roofing is widely used for commercial and industrial flat roofs due to its excellent heat-reflective properties and resistance to UV radiation, making it suitable for buildings in warm climates. EPDM roofing is preferred for low-slope residential and commercial roofs because of its exceptional durability, flexibility, and resistance to weathering and ozone exposure, ideal for areas with varying temperatures. Both materials provide strong waterproofing but differ in compatibility with roof designs and environmental conditions, influencing their common applications.

Final Verdict: Choosing Between TPO and EPDM

TPO roofing offers superior energy efficiency and UV resistance, making it ideal for environments with high sun exposure, while EPDM roofing excels in durability and weather resistance, particularly in colder climates. TPO membranes are typically lighter and easier to install, reducing labor costs, whereas EPDM provides exceptional flexibility and longevity with proven performance over decades. Selecting between TPO and EPDM depends on budget, climate considerations, and long-term maintenance priorities to optimize roofing lifespan and overall building protection.

TPO roofing vs EPDM roofing Infographic

libmatt.com

libmatt.com