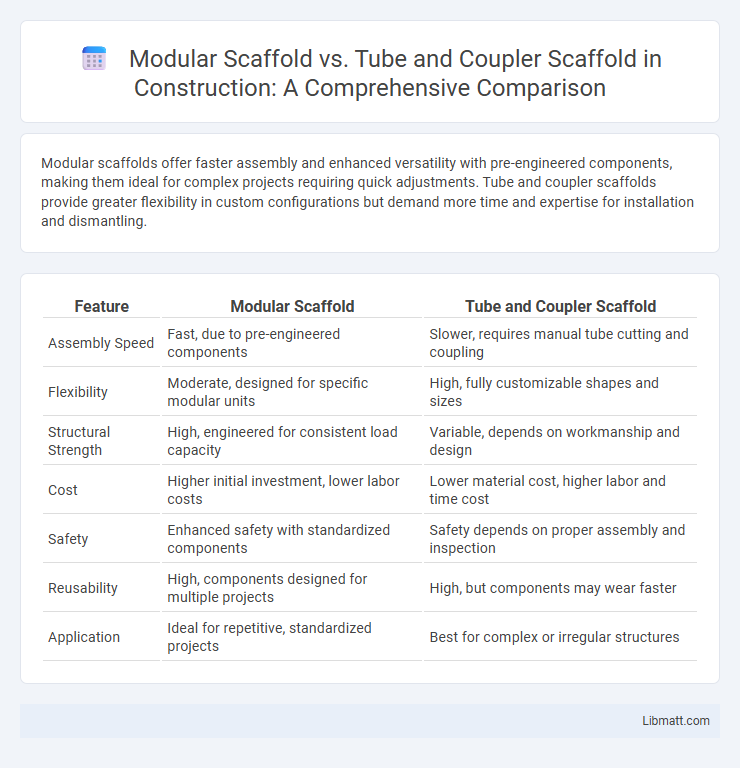

Modular scaffolds offer faster assembly and enhanced versatility with pre-engineered components, making them ideal for complex projects requiring quick adjustments. Tube and coupler scaffolds provide greater flexibility in custom configurations but demand more time and expertise for installation and dismantling.

Table of Comparison

| Feature | Modular Scaffold | Tube and Coupler Scaffold |

|---|---|---|

| Assembly Speed | Fast, due to pre-engineered components | Slower, requires manual tube cutting and coupling |

| Flexibility | Moderate, designed for specific modular units | High, fully customizable shapes and sizes |

| Structural Strength | High, engineered for consistent load capacity | Variable, depends on workmanship and design |

| Cost | Higher initial investment, lower labor costs | Lower material cost, higher labor and time cost |

| Safety | Enhanced safety with standardized components | Safety depends on proper assembly and inspection |

| Reusability | High, components designed for multiple projects | High, but components may wear faster |

| Application | Ideal for repetitive, standardized projects | Best for complex or irregular structures |

Introduction to Scaffolding Systems

Modular scaffold systems offer pre-engineered components that allow for quick assembly and flexible configurations, enhancing efficiency and safety on construction sites. Tube and coupler scaffolds consist of individual tubes connected by clamps, providing customizable setups but requiring more time and skill to erect securely. Your choice between modular and tube and coupler scaffolding depends on project complexity, time constraints, and the need for adaptability.

Overview of Modular Scaffolding

Modular scaffolding consists of pre-engineered components such as frames, braces, and couplers designed for quick assembly and high flexibility in complex structures. Tube and coupler scaffolding relies on separate steel tubes joined by couplers, offering maximum customization but requiring more time and skilled labor for setup. Modular scaffolding enhances safety, efficiency, and adaptability in construction projects, particularly for repetitive tasks and standardized designs.

Overview of Tube and Coupler Scaffolding

Tube and coupler scaffolding consists of steel tubes connected by clamps or couplers, offering flexibility in height and length adjustments for diverse construction needs. This type of scaffolding is widely used due to its simplicity in assembly, adaptability to irregular structures, and cost-effectiveness for short-term projects. Its primary advantage lies in the customizable framework, making it suitable for complex or uniquely shaped work environments compared to modular scaffolding systems.

Key Differences Between Modular and Tube & Coupler Scaffolds

Modular scaffolds feature pre-engineered components with standardized connections, allowing for faster assembly and greater design flexibility compared to tube and coupler scaffolds, which rely on individual tubes and fittings assembled manually, often requiring more time and labor. Tube and coupler scaffolds provide adaptability for irregular structures and complex configurations, but modular systems offer superior ease of use, enhanced safety due to factory-tested connections, and improved load-bearing capabilities. These distinctions impact project efficiency, safety compliance, and suitability depending on construction demands and site conditions.

Structural Strength and Stability Comparison

Modular scaffolds offer superior structural strength and stability due to their designed interlocking components and engineered load distribution, making them ideal for complex and high-load applications. Tube and coupler scaffolds rely on manual assembly of tubes and fittings, which can introduce variability in stability and require precise workmanship to achieve comparable strength. Engineered modular systems typically exceed the load capacity and rigidity of tube and coupler scaffolds, enhancing safety in large-scale construction projects.

Safety Features and Compliance

Modular scaffolds offer enhanced safety features with standardized components and integrated guardrails that ensure consistent compliance with OSHA and ANSI regulations. Tube and coupler scaffolds require skilled assembly to meet safety standards, relying heavily on worker expertise to secure connections and maintain stability. Your choice should prioritize regulatory compliance and the scaffold system's ability to minimize fall hazards effectively.

Flexibility and Versatility in Applications

Modular scaffolds provide superior flexibility and versatility compared to tube and coupler scaffolds due to their pre-engineered design, enabling quick assembly and adaptability to complex structures. Tube and coupler scaffolds offer customization through manual connection of tubes and couplers but require more time and skill to adjust for varying heights and shapes. Your choice depends on project complexity, with modular systems excelling in efficiency for repetitive or intricate tasks, while tube and coupler scaffolds suit more straightforward, bespoke applications.

Installation Speed and Labor Requirements

Modular scaffolds feature pre-engineered, standardized components that significantly reduce installation time compared to tube and coupler scaffolds, which require manual fitting of individual tubes and couplers. The streamlined assembly process of modular systems lowers labor demand, enabling fewer workers to erect extensive structures efficiently. Your choice of modular scaffold can enhance project timelines while minimizing workforce costs on complex construction sites.

Cost Efficiency and Budget Considerations

Modular scaffolds generally offer greater cost efficiency for complex projects due to their quicker assembly and disassembly, reducing labor costs and minimizing downtime. Tube and coupler scaffolds, while more labor-intensive, can be more budget-friendly for simple or irregular structures since their materials are often less expensive. Your choice depends on project complexity and timeline, with modular scaffolds typically yielding better overall budget control on large-scale jobs.

Choosing the Right Scaffolding System for Your Project

Modular scaffolds offer quick assembly and flexibility with pre-engineered components ideal for complex structures, while tube and coupler scaffolds provide customizable configurations suitable for irregular surfaces and extensive height. Selecting the right scaffolding system depends on project scale, complexity, safety requirements, and site conditions, with modular systems favoring efficiency and tube and coupler excelling in adaptability. Evaluate load capacity, ease of erection, and compliance with relevant safety standards to ensure optimal performance and cost-effectiveness.

Modular scaffold vs tube and coupler scaffold Infographic

libmatt.com

libmatt.com