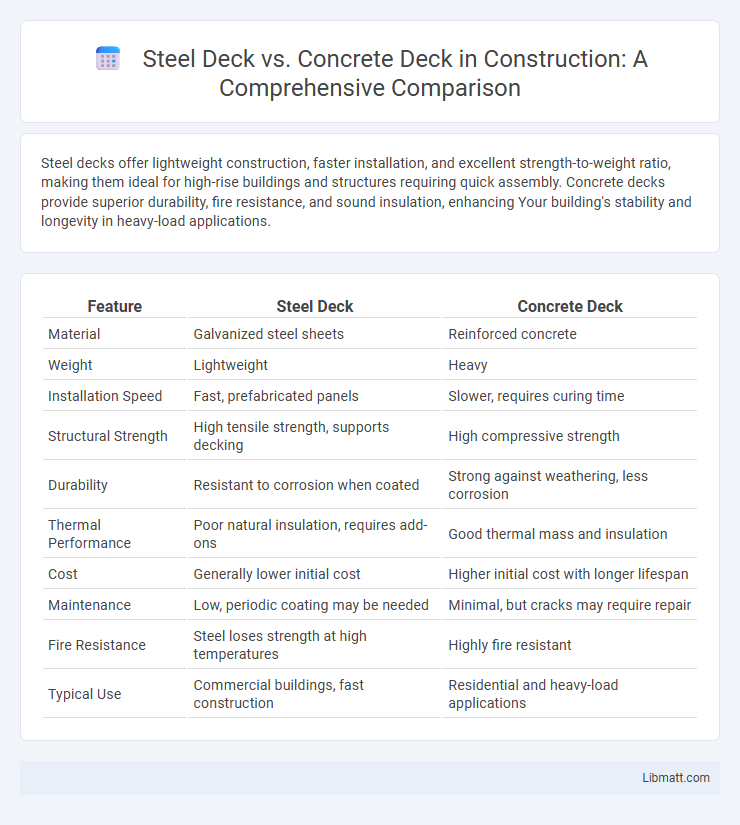

Steel decks offer lightweight construction, faster installation, and excellent strength-to-weight ratio, making them ideal for high-rise buildings and structures requiring quick assembly. Concrete decks provide superior durability, fire resistance, and sound insulation, enhancing Your building's stability and longevity in heavy-load applications.

Table of Comparison

| Feature | Steel Deck | Concrete Deck |

|---|---|---|

| Material | Galvanized steel sheets | Reinforced concrete |

| Weight | Lightweight | Heavy |

| Installation Speed | Fast, prefabricated panels | Slower, requires curing time |

| Structural Strength | High tensile strength, supports decking | High compressive strength |

| Durability | Resistant to corrosion when coated | Strong against weathering, less corrosion |

| Thermal Performance | Poor natural insulation, requires add-ons | Good thermal mass and insulation |

| Cost | Generally lower initial cost | Higher initial cost with longer lifespan |

| Maintenance | Low, periodic coating may be needed | Minimal, but cracks may require repair |

| Fire Resistance | Steel loses strength at high temperatures | Highly fire resistant |

| Typical Use | Commercial buildings, fast construction | Residential and heavy-load applications |

Introduction to Steel Decks and Concrete Decks

Steel decks consist of corrugated metal panels used as structural flooring or roofing systems, offering high strength-to-weight ratios and quick installation times. Concrete decks typically involve reinforced concrete slabs providing excellent compression strength, fire resistance, and durability for various construction applications. Both deck types serve as essential components in building frameworks, with steel decks often combined with concrete to create composite floor systems that enhance load capacity and structural performance.

Structural Composition and Materials

Steel decks consist of corrugated steel panels that provide a strong, lightweight structural base, often used as a formwork for concrete slabs or as a standalone floor system. Concrete decks involve reinforced concrete poured over formwork, offering high compressive strength and durability suitable for heavy loads and diverse environmental conditions. Your choice depends on the required load capacity, construction speed, and design flexibility, with steel decks excelling in rapid installation and concrete decks providing superior mass and fire resistance.

Installation Process and Construction Time

Steel deck installation involves placing prefabricated metal sheets quickly over the structural framework, reducing labor time and allowing immediate placement of concrete. Concrete decks require formwork setup, reinforcement placement, and curing time, which extends the overall construction duration. The steel deck method accelerates the process by combining structural support and concrete form in one step, significantly cutting down construction time compared to traditional concrete deck installation.

Load-Bearing Capacity and Structural Performance

Steel decks offer superior load-bearing capacity due to their high tensile strength and ability to span long distances with minimal support, making them ideal for heavy structural loads and dynamic forces. Concrete decks provide excellent compressive strength and durability, distributing loads more evenly across a larger surface area, which enhances resistance to concentrated loads and impacts. Structural performance in steel decks benefits from lightweight properties and flexibility, while concrete decks excel in stiffness and fire resistance, influencing their suitability based on specific engineering requirements.

Durability and Lifespan Comparison

Steel decks offer superior durability due to their resistance to cracking, corrosion, and environmental deterioration, typically lasting 50 years or more with proper maintenance. Concrete decks, while strong and fire-resistant, are prone to cracking, spalling, and require regular sealing to extend their lifespan, generally lasting around 30 to 40 years. Choosing a steel deck can enhance Your structure's longevity and reduce long-term maintenance costs compared to a concrete deck.

Cost Analysis: Initial and Long-Term Expenses

Steel decks typically have lower initial costs due to faster installation and reduced labor requirements compared to concrete decks, which require more time for curing and formwork. Long-term expenses favor concrete decks because of their superior durability, lower maintenance needs, and better resistance to corrosion and wear over time. Evaluating total life-cycle costs often reveals that concrete decks offer better value for infrastructure projects demanding longevity and minimal upkeep.

Fire Resistance and Safety features

Steel decks offer limited inherent fire resistance but can be coated with fireproofing materials to meet safety standards, preventing structural failure during high-temperature exposure. Concrete decks provide superior fire resistance due to their non-combustible nature and thermal mass, which slows heat transfer and protects underlying structures. For your building's safety, selecting a concrete deck enhances fire protection without requiring additional treatments, whereas steel decks demand careful fireproofing application.

Maintenance Requirements and Longevity

Steel decks require regular inspections to prevent corrosion and may need periodic repainting or protective coatings to extend their lifespan. Concrete decks generally have lower maintenance demands, benefiting from inherent durability and resistance to weathering, though they may require crack repairs over time. Longevity of concrete decks typically surpasses steel decks due to their robustness, but steel decks can achieve comparable service life with proper upkeep.

Sustainability and Environmental Impact

Steel decks offer high recyclability and lower raw material consumption, reducing environmental impact through minimized construction waste and enhanced durability. Concrete decks incorporate sustainable materials such as supplementary cementitious substances, promoting carbon footprint reduction but typically involve higher embodied energy during production. Choosing between steel and concrete decks depends on balancing recyclability and lifecycle emissions with project-specific sustainability goals.

Application Suitability and Recommended Uses

Steel decks are highly suitable for commercial and industrial buildings where rapid installation and lightweight structures are prioritized, making them ideal for multi-story buildings and bridges. Concrete decks offer superior durability and load-bearing capacity, making them the preferred choice for highways, parking structures, and heavy-duty applications. Engineers recommend steel decks for projects requiring flexibility and speed, while concrete decks are favored for long-term strength and resistance in infrastructure with high traffic loads.

Steel deck vs concrete deck Infographic

libmatt.com

libmatt.com