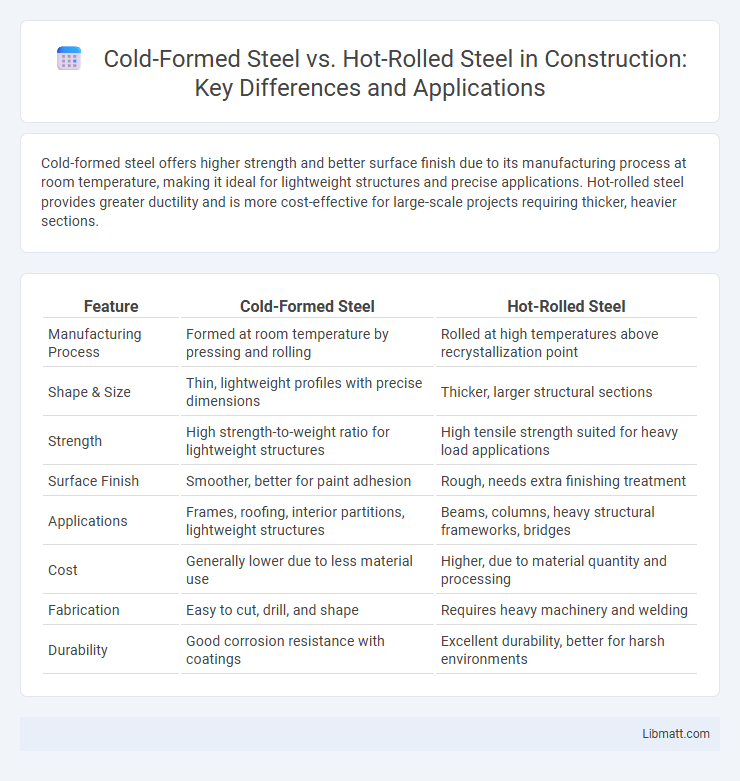

Cold-formed steel offers higher strength and better surface finish due to its manufacturing process at room temperature, making it ideal for lightweight structures and precise applications. Hot-rolled steel provides greater ductility and is more cost-effective for large-scale projects requiring thicker, heavier sections.

Table of Comparison

| Feature | Cold-Formed Steel | Hot-Rolled Steel |

|---|---|---|

| Manufacturing Process | Formed at room temperature by pressing and rolling | Rolled at high temperatures above recrystallization point |

| Shape & Size | Thin, lightweight profiles with precise dimensions | Thicker, larger structural sections |

| Strength | High strength-to-weight ratio for lightweight structures | High tensile strength suited for heavy load applications |

| Surface Finish | Smoother, better for paint adhesion | Rough, needs extra finishing treatment |

| Applications | Frames, roofing, interior partitions, lightweight structures | Beams, columns, heavy structural frameworks, bridges |

| Cost | Generally lower due to less material use | Higher, due to material quantity and processing |

| Fabrication | Easy to cut, drill, and shape | Requires heavy machinery and welding |

| Durability | Good corrosion resistance with coatings | Excellent durability, better for harsh environments |

Introduction to Cold-Formed and Hot-Rolled Steel

Cold-formed steel is produced by shaping steel sheets at room temperature, resulting in high strength and precise dimensions ideal for lightweight construction applications. Hot-rolled steel is manufactured by rolling steel at high temperatures, enhancing its ductility and allowing it to be formed into larger, thicker sections used in heavy structural frameworks. The distinct manufacturing processes influence the mechanical properties and typical uses of each steel type in construction and industrial design.

Manufacturing Processes: Cold-Formed vs Hot-Rolled

Cold-formed steel is manufactured by bending or pressing steel sheets at room temperature, resulting in precise shapes with improved surface finish and higher strength due to work hardening. Hot-rolled steel is produced by rolling steel at temperatures above its recrystallization point, which allows for easier shaping and results in a more ductile material with a rougher surface texture. The manufacturing process impacts mechanical properties, dimensional tolerances, and typical applications, with cold-formed steel being favored for lightweight structural uses and hot-rolled steel suited for heavy-duty construction.

Structural and Mechanical Properties Comparison

Cold-formed steel exhibits higher yield strength and greater dimensional accuracy due to work hardening during the forming process, making it ideal for lightweight structural applications. Hot-rolled steel features better ductility and toughness, which provides superior performance under dynamic and heavy load conditions in construction. The choice between the two materials depends on the required balance of strength, formability, and load-bearing capacity in structural design.

Applications in Construction and Industry

Cold-formed steel is widely used in lightweight steel framing, roofing, and interior partitions due to its high strength-to-weight ratio and precise tolerances, making it ideal for residential and commercial buildings. Hot-rolled steel features superior toughness and ductility, often employed in heavy structural components like beams, columns, and bridges requiring significant load-bearing capacity. Both materials play crucial roles in construction and industrial applications, with cold-formed steel favored for efficiency and design flexibility, while hot-rolled steel supports heavy-duty structural integrity.

Cost Efficiency and Economic Considerations

Cold-formed steel typically offers greater cost efficiency due to lower energy consumption during production and reduced material waste compared to hot-rolled steel. Hot-rolled steel, while more expensive upfront, provides superior structural strength and durability, which can decrease long-term maintenance and replacement costs in heavy-load applications. Choosing between cold-formed and hot-rolled steel depends on project budgets, load requirements, and lifecycle cost analysis to optimize economic benefits.

Strengths and Limitations of Cold-Formed Steel

Cold-formed steel offers high strength-to-weight ratio, excellent precision in manufacturing, and enhanced corrosion resistance due to its thin gauge and cold-working process, making it ideal for lightweight framing and detailed structural components. Its limitations include lower ductility compared to hot-rolled steel, susceptibility to local buckling, and challenges in welding thicker sections. Your choice between cold-formed and hot-rolled steel should consider these factors based on specific application requirements and load conditions.

Strengths and Limitations of Hot-Rolled Steel

Hot-rolled steel is known for its high strength, excellent ductility, and cost-effectiveness, making it ideal for structural applications like beams and rails that require durability and toughness. Its manufacturing process allows for the production of large and complex shapes but often results in a rougher surface finish and less precise tolerances compared to cold-formed steel. Understanding these strengths and limitations helps you select the best material based on project specifications and performance requirements.

Sustainability and Environmental Impact

Cold-formed steel has a lower environmental impact due to its efficient use of material and reduced energy consumption during production compared to hot-rolled steel. The recycling rate of cold-formed steel exceeds 90%, minimizing waste and supporting circular economy principles. Hot-rolled steel generally requires higher processing temperatures, resulting in increased greenhouse gas emissions and energy use, making it less sustainable in comparison.

Choosing the Right Steel for Your Project

Cold-formed steel offers higher strength-to-weight ratios and precise thickness control, making it ideal for lightweight, high-precision applications such as framing and cladding. Hot-rolled steel provides superior ductility and toughness with a more uniform grain structure, which benefits structural components requiring durability and impact resistance. Understanding your project's load-bearing requirements and environmental conditions ensures you select cold-formed steel for flexibility and detailed work, or hot-rolled steel for heavy-duty, robust construction.

Future Trends in Steel Manufacturing

Future trends in steel manufacturing emphasize advancements in cold-formed steel due to its enhanced strength-to-weight ratio and energy efficiency compared to hot-rolled steel. Innovations in automation and precision control are driving the increased adoption of cold-formed steel in construction and automotive industries, promoting sustainability through reduced material waste and lower carbon emissions. Meanwhile, hot-rolled steel continues evolving with improved alloy compositions and heat treatment processes to meet the demands of heavy industrial applications requiring high durability.

Cold-formed steel vs Hot-rolled steel Infographic

libmatt.com

libmatt.com