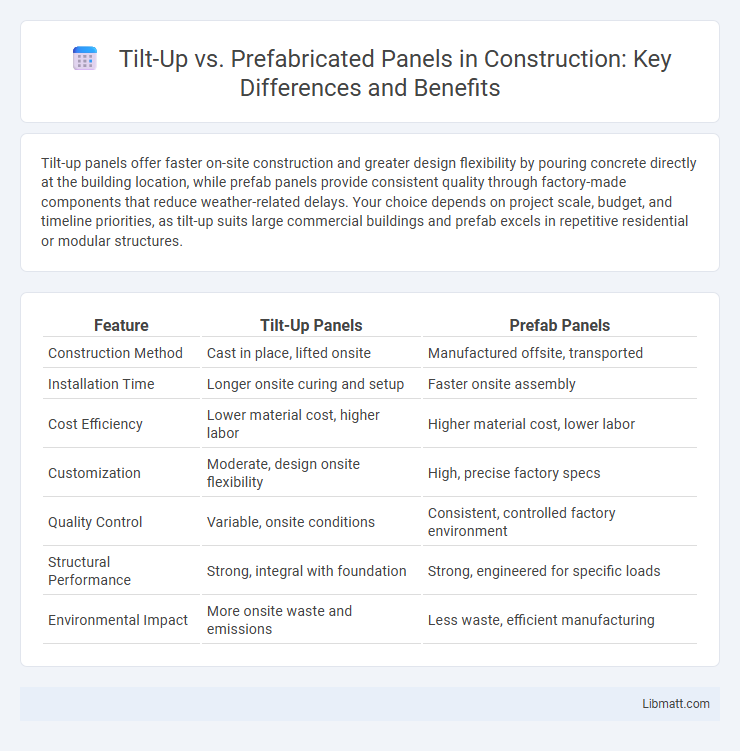

Tilt-up panels offer faster on-site construction and greater design flexibility by pouring concrete directly at the building location, while prefab panels provide consistent quality through factory-made components that reduce weather-related delays. Your choice depends on project scale, budget, and timeline priorities, as tilt-up suits large commercial buildings and prefab excels in repetitive residential or modular structures.

Table of Comparison

| Feature | Tilt-Up Panels | Prefab Panels |

|---|---|---|

| Construction Method | Cast in place, lifted onsite | Manufactured offsite, transported |

| Installation Time | Longer onsite curing and setup | Faster onsite assembly |

| Cost Efficiency | Lower material cost, higher labor | Higher material cost, lower labor |

| Customization | Moderate, design onsite flexibility | High, precise factory specs |

| Quality Control | Variable, onsite conditions | Consistent, controlled factory environment |

| Structural Performance | Strong, integral with foundation | Strong, engineered for specific loads |

| Environmental Impact | More onsite waste and emissions | Less waste, efficient manufacturing |

Overview: Tilt-Up vs Prefab Panels

Tilt-up construction involves casting concrete panels on-site and then tilting them into place, offering rapid assembly and reduced transportation costs. Prefab panels are manufactured off-site in controlled environments, ensuring higher precision, quality control, and faster installation times at the construction site. Both methods enhance efficiency, but tilt-up suits large-scale commercial projects while prefab panels are ideal for complex designs requiring customization.

Construction Process Comparison

Tilt-up construction involves casting concrete panels on-site and then lifting them into place, reducing transportation costs and allowing for rapid erection. Prefabricated panels are manufactured off-site in controlled environments, ensuring consistent quality and accelerated production schedules, but requiring careful logistics for transportation and crane availability. The tilt-up method offers flexibility for customization during construction, while prefab panels provide quicker installation with potentially less on-site labor.

Material Costs and Budget Considerations

Tilt-up construction typically involves lower material costs due to on-site casting using standard concrete and formwork, making it a budget-friendly option for large projects with easy site access. Prefab panels often entail higher upfront expenses since panels are manufactured off-site using specialized materials and transport logistics, which can increase overall budget requirements. Understanding your project's scale and site conditions helps optimize material costs, ensuring efficient budget allocation between tilt-up and prefab panel methods.

Design Flexibility and Customization

Tilt-up construction offers greater design flexibility and customization by allowing on-site casting of concrete panels tailored to specific architectural requirements and unique site conditions. Prefabricated panels, while efficient and faster to install, typically come in standardized sizes and designs, limiting customization options and requiring careful coordination during the design phase. Engineers and architects often prefer tilt-up for projects demanding bespoke aesthetics and complex geometries, whereas prefab panels suit repetitive, modular designs with tighter schedules.

Speed and Efficiency of Installation

Tilt-up panels offer rapid installation by casting concrete slabs directly on-site, reducing transportation time and allowing large sections of a building to be erected in days. Prefabricated panels provide consistent quality and precision manufacturing off-site, enabling simultaneous site preparation and panel production, which enhances overall project timelines. Both methods significantly improve construction speed and efficiency compared to traditional masonry, with tilt-up excelling in large, straightforward designs and prefab panels favoring complex, modular structures.

Structural Strength and Durability

Tilt-up panels offer exceptional structural strength due to their monolithic concrete casting on-site, which results in fewer joints and enhanced load-bearing capacity. Prefabricated panels, manufactured under controlled factory conditions, provide consistent durability with high-quality materials and precise reinforcement, although they may require additional sealing at joints to prevent long-term degradation. Both systems deliver robust performance, but tilt-up construction typically excels in withstanding heavy loads and seismic forces, while prefab panels provide uniform strength and resistance to weathering.

Sustainability and Environmental Impact

Tilt-up construction reduces waste by casting concrete panels on-site, minimizing transportation emissions and allowing for efficient use of materials. Prefabricated panels offer precise manufacturing processes that reduce material waste and enable better control over insulation, enhancing energy efficiency in buildings. Both methods contribute to green building practices, but prefab panels often provide superior opportunities for incorporating recycled materials and achieving LEED certifications.

Labor Requirements and Skillsets

Tilt-up construction demands skilled laborers proficient in concrete pouring, formwork, and crane operation for panel lifting, making it labor-intensive on-site. Prefabricated panels require less on-site labor but depend heavily on factory-trained workers for precise manufacturing and quality control. Your choice between the two impacts project staffing needs, with tilt-up favoring experienced field crews and prefab panels relying more on specialized off-site production teams.

Common Applications and Project Types

Tilt-up panels are commonly used in commercial warehouses, retail stores, and large industrial buildings due to their strength and cost-effectiveness for expansive wall surfaces. Prefabricated panels suit projects requiring faster installation and intricate architectural designs, such as multifamily housing, office buildings, and institutional facilities. Your choice depends on project size, design complexity, and construction timeline priorities.

Choosing the Right Method for Your Project

Tilt-up construction offers faster on-site assembly and cost efficiency for large-scale commercial projects, while prefab panels provide superior quality control and flexibility for complex architectural designs. Evaluating project size, timeline, budget, and design requirements will help determine if tilt-up's rapid installation or prefab's factory precision better suits your construction needs. Your choice influences structural performance, labor demands, and long-term maintenance considerations.

Tilt-up vs prefab panels Infographic

libmatt.com

libmatt.com