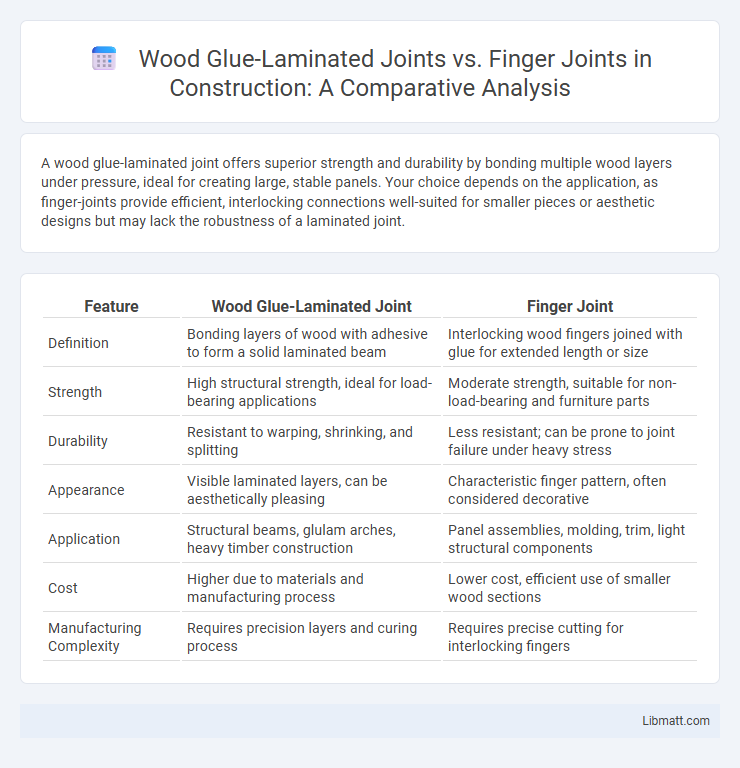

A wood glue-laminated joint offers superior strength and durability by bonding multiple wood layers under pressure, ideal for creating large, stable panels. Your choice depends on the application, as finger-joints provide efficient, interlocking connections well-suited for smaller pieces or aesthetic designs but may lack the robustness of a laminated joint.

Table of Comparison

| Feature | Wood Glue-Laminated Joint | Finger Joint |

|---|---|---|

| Definition | Bonding layers of wood with adhesive to form a solid laminated beam | Interlocking wood fingers joined with glue for extended length or size |

| Strength | High structural strength, ideal for load-bearing applications | Moderate strength, suitable for non-load-bearing and furniture parts |

| Durability | Resistant to warping, shrinking, and splitting | Less resistant; can be prone to joint failure under heavy stress |

| Appearance | Visible laminated layers, can be aesthetically pleasing | Characteristic finger pattern, often considered decorative |

| Application | Structural beams, glulam arches, heavy timber construction | Panel assemblies, molding, trim, light structural components |

| Cost | Higher due to materials and manufacturing process | Lower cost, efficient use of smaller wood sections |

| Manufacturing Complexity | Requires precision layers and curing process | Requires precise cutting for interlocking fingers |

Introduction to Wood Joints

Wood glue-laminated joints involve bonding multiple wood layers with strong adhesive to create thick, stable components commonly used in structural applications. Finger joints interlock wood pieces with complementary notches, increasing the glued surface area for enhanced strength in smaller or narrower boards. Your choice between these wood joints depends on the required strength, appearance, and intended use of the final woodworking project.

Overview of Glue-Laminated Joints

Glue-laminated joints, often referred to as glulam, involve bonding multiple layers of wood together with strong adhesives to form a single structural element that offers enhanced strength and stability. These joints rely on the uniform distribution of glue lines and precise alignment, creating a durable bond capable of withstanding significant load stresses. Compared to finger-joints, glue-laminated joints provide greater dimensional stability and are commonly used in large-scale structural applications like beams and columns.

Understanding Finger-Joint Construction

Finger-joint construction involves interlocking multiple wood segments with precision-cut fingers to create a strong, elongated joint, enhancing structural integrity in wood products. This method improves the stability and uniformity of lumber compared to traditional scarfing techniques, making it ideal for applications needing extended lengths without compromising strength. Your choice between wood glue-laminated joints and finger-joints should consider the specific load-bearing requirements and aesthetic preferences of the project.

Strength Comparison: Glue-Laminated vs Finger-Joint

Wood glue-laminated joints exhibit superior strength due to multiple layers bonded with durable adhesives, distributing loads evenly and enhancing structural integrity. Finger-joint connections, characterized by interlocking teeth glued together, provide moderate strength but may be prone to failure under high stress or moisture exposure. For optimal durability in load-bearing applications, your choice should favor glue-laminated joints over finger-joints.

Applications in Modern Woodworking

Wood glue-laminated joints excel in structural applications such as beams and large panels, providing superior strength and stability for modern timber construction and furniture making. Finger-joints are ideal for creating long, straight wood pieces from shorterstock, commonly used in molding, trim, and flooring where continuous lengths are essential. Your choice depends on the required load-bearing capacity and aesthetic finish needed for the woodworking project.

Durability and Longevity Factors

Wood glue-laminated joints exhibit superior durability due to uniform stress distribution and strong adhesive bonds that resist moisture and temperature fluctuations, extending the lifespan of laminated timber structures. Finger-joints, while effective for lengthening wood pieces, rely heavily on precise machining and adhesive quality, which can be vulnerable to shear stress and water exposure, potentially reducing their longevity under harsh conditions. Environmental resistance and the type of adhesive used in both joints are critical factors impacting the overall durability and long-term performance of wooden assemblies.

Aesthetic Considerations and Finishes

Wood glue-laminated joints offer a seamless and smooth appearance ideal for visible structural elements, allowing for a variety of finishes such as staining, painting, or varnishing without disrupting the grain pattern. Finger-joints create a distinct, interlocking pattern that adds a decorative element but may require extra surface preparation to achieve a uniform finish. Both joint types impact the final aesthetic, with glulam favoring a clean, continuous look and finger-joints emphasizing texture and craftsmanship.

Cost Effectiveness and Material Efficiency

Wood glue-laminated joints offer superior material efficiency by bonding large, solid wood pieces together, reducing waste and providing high strength for structural applications. Finger joints are cost-effective due to faster production and the ability to use smaller, lower-quality wood pieces, making them ideal for manufacturing without compromising durability. Your choice depends on balancing initial costs with long-term material performance and project requirements.

Environmental Impact and Sustainability

Wood glue-laminated joints typically use adhesives that may contain chemicals impacting indoor air quality and require energy-intensive processing, whereas finger-joints can utilize smaller wood pieces, promoting resource efficiency and reducing waste. Your choice between these joints influences material sustainability; finger-joints often enable the use of lower-grade timber, contributing to forest conservation and lowering overall carbon footprint. Evaluating manufacturer practices and adhesive types further ensures a sustainable approach tailored to environmental impact goals.

Choosing the Right Joint for Your Project

Wood glue-laminated joints offer superior strength and durability, making them ideal for load-bearing structures and large wooden beams. Finger joints provide efficient material usage and aesthetic appeal, suitable for decorative applications and smaller panels. Selecting the right joint depends on the project's structural requirements, appearance preferences, and the type of wood being used.

Wood glue-laminated joint vs finger-joint Infographic

libmatt.com

libmatt.com