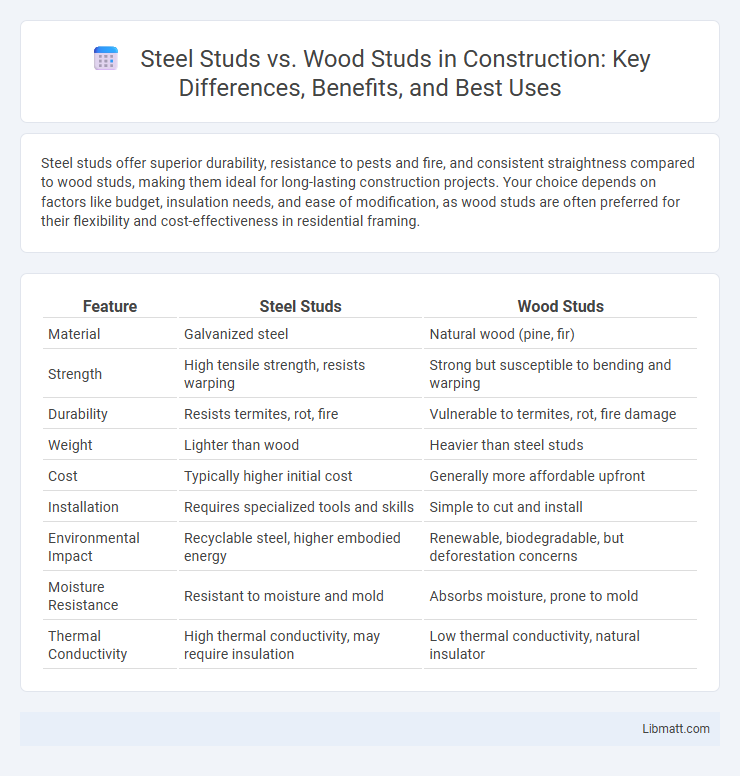

Steel studs offer superior durability, resistance to pests and fire, and consistent straightness compared to wood studs, making them ideal for long-lasting construction projects. Your choice depends on factors like budget, insulation needs, and ease of modification, as wood studs are often preferred for their flexibility and cost-effectiveness in residential framing.

Table of Comparison

| Feature | Steel Studs | Wood Studs |

|---|---|---|

| Material | Galvanized steel | Natural wood (pine, fir) |

| Strength | High tensile strength, resists warping | Strong but susceptible to bending and warping |

| Durability | Resists termites, rot, fire | Vulnerable to termites, rot, fire damage |

| Weight | Lighter than wood | Heavier than steel studs |

| Cost | Typically higher initial cost | Generally more affordable upfront |

| Installation | Requires specialized tools and skills | Simple to cut and install |

| Environmental Impact | Recyclable steel, higher embodied energy | Renewable, biodegradable, but deforestation concerns |

| Moisture Resistance | Resistant to moisture and mold | Absorbs moisture, prone to mold |

| Thermal Conductivity | High thermal conductivity, may require insulation | Low thermal conductivity, natural insulator |

Introduction to Steel Studs vs Wood Studs

Steel studs offer superior durability, resistance to pests, and non-combustibility compared to traditional wood studs used in construction framing. Wood studs provide natural insulation and are easier to cut and modify on-site, making them a preferred choice for many residential projects. Your decision between steel and wood studs should consider factors like project requirements, environmental conditions, and long-term maintenance needs.

Material Composition and Manufacturing

Steel studs are manufactured from galvanized cold-rolled steel sheets, offering high tensile strength, uniformity, and resistance to warping, rot, and insect damage compared to wood studs, which are composed of natural timber prone to variability in density and grain. The manufacturing process of steel studs involves precision stamping and forming, ensuring consistent dimensions and straightness, whereas wood studs are cut and planed from logs, which can result in knots, splits, and uneven surfaces. The corrosion resistance of steel is enhanced by galvanization, while wood requires chemical treatments to improve durability and resistance to moisture and pests.

Strength and Durability Comparison

Steel studs offer superior strength-to-weight ratio compared to wood studs, making them highly resistant to warping, twisting, and splitting over time. Wood studs can absorb moisture, leading to potential rot, mold, and termite damage, whereas steel studs are impervious to these risks and provide consistent structural integrity. In high-moisture or termite-prone environments, steel studs deliver greater longevity and reduced maintenance costs relative to traditional wood framing.

Cost Analysis: Steel vs Wood

Steel studs generally cost more upfront than wood studs, with prices varying based on gauge and market demand; steel ranges from $3 to $4 per linear foot, while wood typically costs $2 to $3. Despite higher initial expenses, steel studs offer long-term savings due to resistance to warping, termites, and fire, reducing maintenance and replacement costs. Wood studs present lower initial costs and easier handling, but can incur additional expenses over time through repairs and insulation adjustments.

Installation Process and Tools Required

Steel studs require specialized tools such as metal snips, screw guns with self-drilling screws, and lightweight framing squares, making the installation process precise yet efficient. Wood studs can be installed using common carpentry tools like hammers, nails, circular saws, and traditional measuring tapes, offering more flexibility for quick adjustments onsite. Your choice between steel and wood studs will influence the ease and speed of framing based on the tools available and the installation techniques you prefer.

Fire Resistance and Safety Considerations

Steel studs offer superior fire resistance compared to wood studs, as they are non-combustible and do not contribute to flame spread, making them a safer choice in fire-prone areas. Wood studs, while less fire-resistant, can be treated with fire-retardant chemicals to improve safety but still remain more vulnerable to ignition and structural compromise during a fire. Your decision should prioritize steel studs for enhanced fire safety, especially in commercial or high-risk residential projects where building codes often require non-combustible framing materials.

Environmental Impact and Sustainability

Steel studs offer enhanced sustainability through their high recyclability and reduced deforestation impact, making them an eco-friendly choice for construction. Wood studs, while renewable and biodegradable, contribute to deforestation and require responsible sourcing to ensure environmental benefits. Your decision between steel and wood studs can significantly influence the overall environmental footprint of your building project.

Common Applications in Construction

Steel studs are commonly used in commercial construction projects such as office buildings, schools, and hospitals due to their durability, fire resistance, and resistance to termites and mold. Wood studs remain popular in residential construction, including single-family homes and light-framing applications, because of their cost-effectiveness, ease of customization, and natural insulating properties. Your choice between steel and wood studs depends on the specific structural requirements, budget, and environmental factors of your construction project.

Maintenance and Longevity

Steel studs require minimal maintenance due to their resistance to warping, rotting, and termite damage, ensuring a longer lifespan compared to wood studs. Wood studs may need regular inspections and treatments to prevent moisture damage and pest infestations, which can reduce their durability. Choosing steel studs can enhance your building's longevity while reducing upkeep costs over time.

Choosing the Right Stud for Your Project

Steel studs offer superior durability, resistance to fire, termites, and warping, making them ideal for commercial buildings and moisture-prone areas, while wood studs provide better insulation, easier customization, and cost-effectiveness favored in residential projects. Your choice should depend on factors such as structural requirements, environmental conditions, and budget constraints to ensure optimal performance and longevity. Evaluating these key attributes will help you select the most suitable stud material for your construction needs.

Steel studs vs wood studs Infographic

libmatt.com

libmatt.com