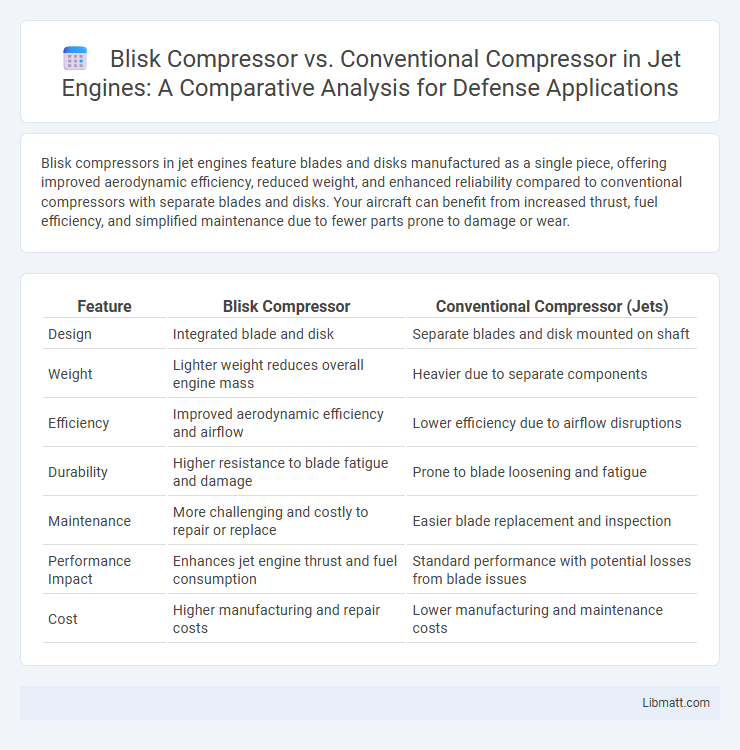

Blisk compressors in jet engines feature blades and disks manufactured as a single piece, offering improved aerodynamic efficiency, reduced weight, and enhanced reliability compared to conventional compressors with separate blades and disks. Your aircraft can benefit from increased thrust, fuel efficiency, and simplified maintenance due to fewer parts prone to damage or wear.

Table of Comparison

| Feature | Blisk Compressor | Conventional Compressor (Jets) |

|---|---|---|

| Design | Integrated blade and disk | Separate blades and disk mounted on shaft |

| Weight | Lighter weight reduces overall engine mass | Heavier due to separate components |

| Efficiency | Improved aerodynamic efficiency and airflow | Lower efficiency due to airflow disruptions |

| Durability | Higher resistance to blade fatigue and damage | Prone to blade loosening and fatigue |

| Maintenance | More challenging and costly to repair or replace | Easier blade replacement and inspection |

| Performance Impact | Enhances jet engine thrust and fuel consumption | Standard performance with potential losses from blade issues |

| Cost | Higher manufacturing and repair costs | Lower manufacturing and maintenance costs |

Introduction to Jet Engine Compressors

Jet engine compressors convert incoming air into high-pressure airflow essential for combustion efficiency and thrust generation. Blisk compressors integrate the blades and disk into a single unit, reducing weight and improving aerodynamic performance compared to conventional compressors with separate blades attached to disks. This design enhances fuel efficiency, decreases maintenance costs, and increases durability by minimizing blade vibration and failure risks.

What is a Blisk Compressor?

A Blisk compressor integrates the blades and disk into a single, seamless component, enhancing aerodynamic efficiency and reducing weight compared to conventional jet compressors that use separate blades attached to a disk. This design improves performance by minimizing blade vibration and increasing structural integrity, leading to better fuel efficiency and lower maintenance costs. Your aircraft engine benefits from greater reliability and reduced operational complexity with a Blisk compressor system.

Conventional Compressor: Design and Function

Conventional compressors in jet engines feature multiple axial stages with rotor blades and stator vanes that progressively increase air pressure through continuous compression. Their intricate design enables efficient airflow management and pressure rise essential for engine thrust and fuel combustion. This multi-stage arrangement, while reliable, results in larger size and weight compared to modern blisk compressors.

Key Differences Between Blisk and Conventional Compressors

Blisk compressors integrate the blade and disk into a single component, enhancing aerodynamic efficiency and reducing weight compared to conventional compressors that use separate blades and disks. The unified design of blisks eliminates blade-root stress concentrations and allows for tighter manufacturing tolerances, resulting in higher engine performance and improved fuel efficiency. Conventional compressors, while easier to repair due to replaceable blades, generally have higher maintenance costs and increased susceptibility to blade vibration and fatigue.

Performance Efficiency Comparison

Blisk compressors offer superior performance efficiency compared to conventional jet compressors by integrating the blades and disk into a single component, reducing aerodynamic losses and weight. This design enhances airflow management, resulting in improved pressure ratios and fuel efficiency for your engine. Consequently, blisk compressors contribute to lower maintenance costs and increased reliability in high-performance jet applications.

Weight and Durability Considerations

Blisk compressors offer significant weight savings compared to conventional jet compressors by integrating the blade and disk into a single component, reducing the number of parts and assembly complexity. This integration enhances durability by minimizing vibration and stress concentrations typical in blade-root interfaces found in traditional compressors. However, blisks require advanced manufacturing and repair techniques, which can impact maintenance efficiency despite their structural advantages.

Maintenance and Repair Implications

Blisk compressors reduce maintenance complexity by eliminating individual blade replacements common in conventional jet compressors, lowering downtime and labor costs. Their integrated design improves operational reliability but can increase repair expenses since damage to a single blade often requires full blisk replacement. Understanding these factors helps you balance long-term maintenance savings against potential repair investments.

Manufacturing Complexity and Cost

Blisk compressors integrate the blade and disk into a single component, resulting in higher manufacturing complexity due to advanced machining and precision assembly requirements compared to conventional jet engine compressors with separate blades and disks. This complexity drives up the initial production cost of blisk compressors, although they offer potential cost savings over time through reduced maintenance and weight. Conventional compressors benefit from simpler, modular manufacturing that allows for easier blade replacement and generally lower upfront costs.

Applications in Modern Jet Engines

Blisk compressors enhance modern jet engine performance by integrating the blade and disk into a single component, reducing weight and improving aerodynamic efficiency compared to conventional compressors with separate blades and disks. This design allows higher rotational speeds and improved fuel efficiency, making them ideal for commercial and military aircraft seeking advanced thrust-to-weight ratios. Your jet engine benefits from blisk technology through reduced maintenance costs and increased overall reliability in demanding aerospace applications.

Future Trends in Compressor Technology

Blisk compressors, integrating blades and disks into a single component, offer enhanced aerodynamic efficiency and reduced weight compared to conventional jet compressors, enabling improved fuel efficiency and performance. Future trends emphasize advanced materials like ceramic matrix composites and additive manufacturing to increase reliability and reduce maintenance costs for blisk compressors. Your choice of compressor technology will be influenced by ongoing developments in smart sensor integration and real-time health monitoring, driving smarter, more adaptive engine designs.

blisk compressor vs conventional compressor (jets) Infographic

libmatt.com

libmatt.com