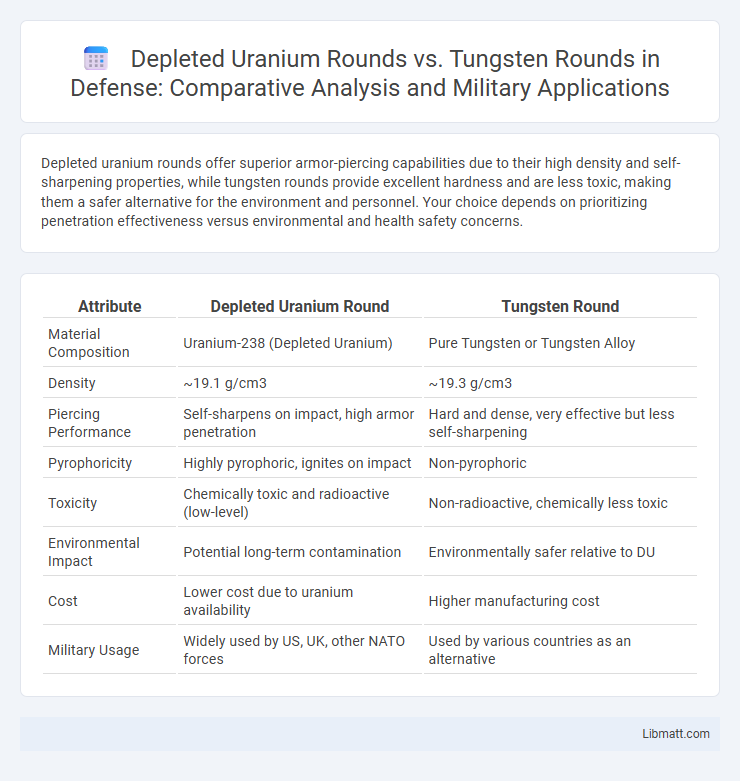

Depleted uranium rounds offer superior armor-piercing capabilities due to their high density and self-sharpening properties, while tungsten rounds provide excellent hardness and are less toxic, making them a safer alternative for the environment and personnel. Your choice depends on prioritizing penetration effectiveness versus environmental and health safety concerns.

Table of Comparison

| Attribute | Depleted Uranium Round | Tungsten Round |

|---|---|---|

| Material Composition | Uranium-238 (Depleted Uranium) | Pure Tungsten or Tungsten Alloy |

| Density | ~19.1 g/cm3 | ~19.3 g/cm3 |

| Piercing Performance | Self-sharpens on impact, high armor penetration | Hard and dense, very effective but less self-sharpening |

| Pyrophoricity | Highly pyrophoric, ignites on impact | Non-pyrophoric |

| Toxicity | Chemically toxic and radioactive (low-level) | Non-radioactive, chemically less toxic |

| Environmental Impact | Potential long-term contamination | Environmentally safer relative to DU |

| Cost | Lower cost due to uranium availability | Higher manufacturing cost |

| Military Usage | Widely used by US, UK, other NATO forces | Used by various countries as an alternative |

Introduction: Depleted Uranium vs. Tungsten Rounds

Depleted uranium rounds offer superior armor penetration due to their higher density (19.1 g/cm3) and pyrophoric properties, enabling them to ignite upon impact, which enhances damage against armored targets. Tungsten rounds, with a density close to depleted uranium (around 19.3 g/cm3), provide excellent penetration while being less toxic and non-pyrophoric, resulting in reduced environmental and health risks. Both materials are preferred in kinetic energy penetrators for tank ammunition, with depleted uranium favored for its self-sharpening behavior during penetration and tungsten for its safer handling characteristics.

Material Composition and Properties

Depleted uranium rounds consist primarily of uranium-238, a dense and pyrophoric metal known for its high density of approximately 19.1 g/cm3, which enhances penetration capabilities against armored targets. Tungsten rounds are composed mainly of tungsten alloys, typically tungsten composite with densities around 17.6-18.5 g/cm3, offering superior hardness and corrosion resistance but lacking uranium's self-sharpening penetration characteristics. The pyrophoric nature of depleted uranium causes it to ignite upon impact, increasing damage effectiveness, whereas tungsten rounds rely on their structural integrity and density for kinetic impact without incendiary effects.

Manufacturing Processes

Depleted uranium rounds are produced by machining and alloying uranium metal, followed by heat treatment to enhance density and pyrophoric properties, making them effective for armor penetration. Tungsten rounds undergo powder metallurgy processes, including powder pressing and sintering, resulting in a dense and hard penetrator with excellent strength and heat resistance. Your choice between these materials depends on manufacturing complexity, cost, and the desired ballistic performance characteristics.

Armor-Penetration Capabilities

Depleted uranium rounds exhibit superior armor-penetration capabilities due to their high density and self-sharpening properties upon impact, allowing them to penetrate heavy armored targets more effectively than tungsten rounds. Tungsten rounds, while dense and hard, tend to blunt or mushroom on impact, reducing their penetration efficiency compared to depleted uranium. The pyrophoric nature of depleted uranium also contributes to additional damage inside armored targets by igniting upon penetration, enhancing its lethality beyond pure kinetic impact.

Performance in Ballistics Testing

Depleted uranium (DU) rounds demonstrate superior penetration capabilities in ballistics testing due to their high density and self-sharpening properties, enabling them to pierce armored targets more effectively than tungsten rounds. Tungsten rounds, while dense and hard, tend to fragment upon impact, reducing their overall penetration performance compared to DU. Your choice between these materials should consider the specific ballistic requirements, as DU excels in defeating heavy armor, whereas tungsten offers safer handling and environmental benefits.

Environmental Impact and Toxicity

Depleted uranium (DU) rounds pose significant environmental risks due to their radioactive and chemically toxic nature, leading to soil and water contamination that can persist for decades. Tungsten rounds, while less radioactive, have been linked to toxicity concerns including potential carcinogenic effects, as tungsten compounds may leach into ecosystems and affect human health. Both materials require careful management and disposal practices to mitigate long-term environmental impact and reduce toxicity risks to wildlife and populations near conflict zones.

Cost-Effectiveness and Availability

Depleted uranium rounds offer lower costs due to uranium's abundance as a byproduct of nuclear fuel processing, making them more economically viable for large-scale military use. Tungsten rounds, though more expensive, provide consistent availability from established mining and refining operations but often require higher production costs due to tungsten's hardness and density. The cost-effectiveness of depleted uranium rounds is favored in scenarios demanding high penetration with budget constraints, while tungsten rounds are preferred where non-toxic alternatives are prioritized.

Military Applications and Usage

Depleted uranium rounds are favored in military applications for their high density and pyrophoric properties, enabling armor penetration and incendiary effects against armored vehicles. Tungsten rounds offer similar hardness and density but lack self-igniting characteristics, making them less effective in creating secondary damage upon penetration. Both materials are widely used in kinetic energy penetrators, with depleted uranium rounds predominantly used by the U.S. military and tungsten rounds preferred by NATO allies.

Health and Safety Considerations

Depleted uranium (DU) rounds pose significant health risks due to their chemical toxicity and low-level radioactivity, which can cause kidney damage and increase long-term cancer risks upon inhalation or ingestion of dust. Tungsten rounds, while generally considered less toxic, have been linked to localized health effects and environmental concerns when particles are embedded in tissues. Proper protective measures and environmental monitoring are essential when handling and disposing of both materials to minimize harmful exposure and ecological impact.

Future Trends in Penetrator Ammunition

Future trends in penetrator ammunition indicate a growing emphasis on tungsten rounds due to their environmental safety and compliance with international regulations restricting depleted uranium use. Advancements in tungsten alloy formulations and manufacturing processes enhance penetration capabilities and reduce material cost, making tungsten a viable substitute for depleted uranium in military applications. Research continues to optimize armor-piercing performance while minimizing ecological impact, driving innovation towards more sustainable and effective penetrator technologies.

depleted uranium round vs tungsten round Infographic

libmatt.com

libmatt.com