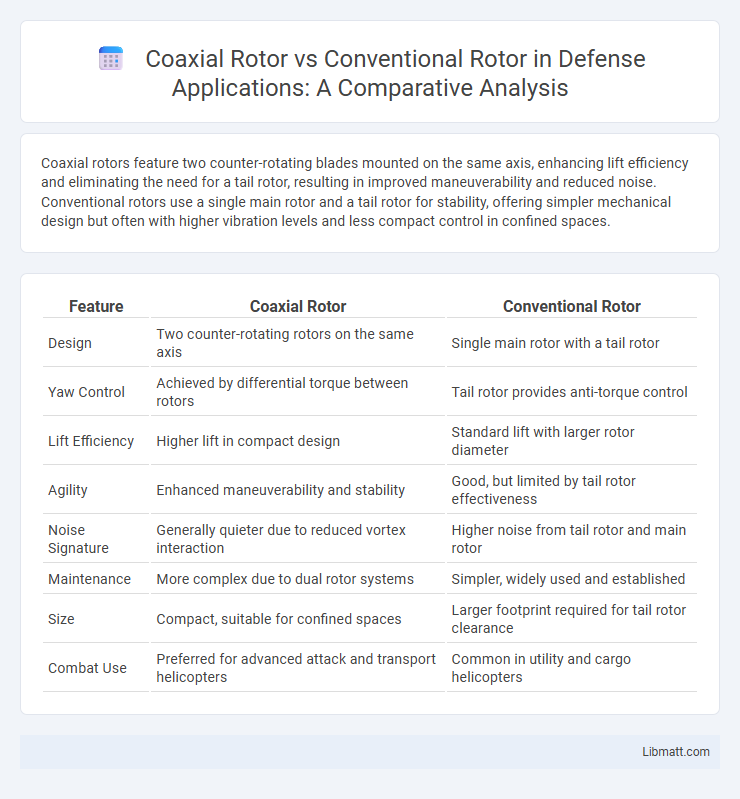

Coaxial rotors feature two counter-rotating blades mounted on the same axis, enhancing lift efficiency and eliminating the need for a tail rotor, resulting in improved maneuverability and reduced noise. Conventional rotors use a single main rotor and a tail rotor for stability, offering simpler mechanical design but often with higher vibration levels and less compact control in confined spaces.

Table of Comparison

| Feature | Coaxial Rotor | Conventional Rotor |

|---|---|---|

| Design | Two counter-rotating rotors on the same axis | Single main rotor with a tail rotor |

| Yaw Control | Achieved by differential torque between rotors | Tail rotor provides anti-torque control |

| Lift Efficiency | Higher lift in compact design | Standard lift with larger rotor diameter |

| Agility | Enhanced maneuverability and stability | Good, but limited by tail rotor effectiveness |

| Noise Signature | Generally quieter due to reduced vortex interaction | Higher noise from tail rotor and main rotor |

| Maintenance | More complex due to dual rotor systems | Simpler, widely used and established |

| Size | Compact, suitable for confined spaces | Larger footprint required for tail rotor clearance |

| Combat Use | Preferred for advanced attack and transport helicopters | Common in utility and cargo helicopters |

Introduction to Rotor Systems

Coaxial rotor systems utilize two counter-rotating rotors mounted one above the other on the same axis, eliminating the need for a tail rotor and enhancing lift efficiency. Conventional rotor systems feature a single main rotor paired with a tail rotor to counteract torque, which influences aircraft maneuverability and complexity. Your choice between these rotor types impacts helicopter performance, control responsiveness, and maintenance requirements.

Overview of Coaxial Rotor Design

Coaxial rotor design features two counter-rotating rotors mounted one above the other on the same axis, eliminating the need for a tail rotor and enhancing lift efficiency. This configuration improves helicopter maneuverability and stability by balancing torque forces inherently. The compact structure of coaxial rotors allows for reduced rotor diameter, making them ideal for confined operational environments.

Conventional Rotor Mechanisms Explained

Conventional rotor systems typically consist of a single main rotor paired with a tail rotor to counteract torque and maintain directional control. These mechanisms rely on complex swashplate assemblies that adjust blade pitch individually, allowing for precise lift and maneuverability. The tail rotor provides anti-torque control, which is essential for stabilizing helicopters during flight and enabling yaw rotation.

Aerodynamic Efficiency Comparison

Coaxial rotors generate higher aerodynamic efficiency by eliminating the need for a tail rotor, reducing power losses and increasing lift-to-drag ratio compared to conventional single rotors. The counter-rotating blades of coaxial systems improve rotational uniformity and reduce vortex formation, enhancing overall thrust performance and stability. Your choice of rotor configuration significantly impacts fuel consumption and flight endurance due to these inherent aerodynamic advantages.

Flight Stability and Control Differences

Coaxial rotors provide enhanced flight stability by counteracting torque through opposing rotor blades, eliminating the need for a tail rotor and enabling more precise yaw control. Conventional rotors rely on a single main rotor with a tail rotor to counteract torque, which can introduce increased mechanical complexity and potential control lag during rapid maneuvers. The aerodynamic efficiency and symmetrical lift distribution of coaxial rotors improve overall control responsiveness and hover performance compared to conventional rotor systems.

Payload Capacity and Performance

Coaxial rotors provide higher payload capacity by producing greater lift efficiency through counter-rotating blades, which eliminate the need for a tail rotor and reduce power losses. This design enhances overall aircraft performance with improved stability, agility, and reduced mechanical complexity compared to conventional rotors. Your choice of rotor system directly impacts the helicopter's operational capabilities, favoring coaxial rotors for missions requiring heavy lifting and maneuverability.

Maintenance and Mechanical Complexity

Coaxial rotors feature dual counter-rotating blades on a single mast, reducing the need for a tail rotor and simplifying directional control but increasing mechanical complexity due to additional gearing and transmission components. Conventional rotor systems rely on a single main rotor with a separate tail rotor for anti-torque, which simplifies mechanical design and maintenance tasks but requires regular attention to tail rotor pitch linkages and driveshafts. Maintenance of coaxial rotors often demands specialized knowledge and tools for synchronizing blade systems, whereas conventional rotors benefit from more established maintenance protocols and easier access to components.

Noise Levels and Environmental Impact

Coaxial rotors generate significantly lower noise levels compared to conventional single-rotor helicopters due to the counter-rotating blades canceling out each other's aerodynamic noise. Reduced noise pollution from coaxial designs benefits urban and wildlife environments by minimizing disturbances and stress. This quieter operation translates into a smaller environmental footprint, promoting sustainability in aviation transportation and attracting regulatory approval for noise-sensitive areas.

Applications in Modern Aviation

Coaxial rotors, featuring two counter-rotating blades on the same axis, are commonly utilized in modern unmanned aerial vehicles (UAVs) and compact helicopters due to their enhanced maneuverability and reduced rotor diameter, which is ideal for urban and confined environments. Conventional rotors dominate in large transport and commercial helicopters like the Sikorsky UH-60 Black Hawk, providing stable lift and simpler mechanical designs suitable for heavy payloads and extended flights. Your choice between coaxial and conventional rotors depends largely on mission requirements such as agility, size constraints, and load capacity in aviation applications.

Future Trends in Rotorcraft Technology

Coaxial rotors offer enhanced efficiency and maneuverability through their counter-rotating blades, reducing torque and improving stability compared to conventional single rotors. Future trends in rotorcraft technology highlight the integration of advanced materials, electric propulsion, and autonomous flight systems, making coaxial rotor designs increasingly favorable for urban air mobility and unmanned applications. Your choice of rotor system will depend on mission requirements and technological advancements driving quieter, more efficient, and versatile rotorcraft.

Coaxial rotor vs Conventional rotor Infographic

libmatt.com

libmatt.com