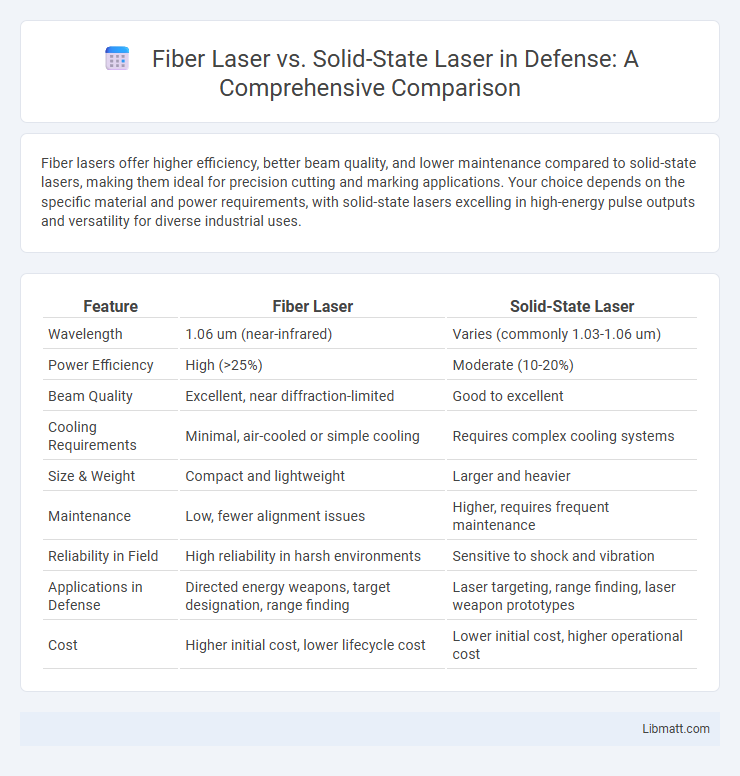

Fiber lasers offer higher efficiency, better beam quality, and lower maintenance compared to solid-state lasers, making them ideal for precision cutting and marking applications. Your choice depends on the specific material and power requirements, with solid-state lasers excelling in high-energy pulse outputs and versatility for diverse industrial uses.

Table of Comparison

| Feature | Fiber Laser | Solid-State Laser |

|---|---|---|

| Wavelength | 1.06 um (near-infrared) | Varies (commonly 1.03-1.06 um) |

| Power Efficiency | High (>25%) | Moderate (10-20%) |

| Beam Quality | Excellent, near diffraction-limited | Good to excellent |

| Cooling Requirements | Minimal, air-cooled or simple cooling | Requires complex cooling systems |

| Size & Weight | Compact and lightweight | Larger and heavier |

| Maintenance | Low, fewer alignment issues | Higher, requires frequent maintenance |

| Reliability in Field | High reliability in harsh environments | Sensitive to shock and vibration |

| Applications in Defense | Directed energy weapons, target designation, range finding | Laser targeting, range finding, laser weapon prototypes |

| Cost | Higher initial cost, lower lifecycle cost | Lower initial cost, higher operational cost |

Introduction to Fiber Lasers and Solid-State Lasers

Fiber lasers utilize optical fibers doped with rare-earth elements such as erbium or ytterbium as the gain medium, enabling high beam quality, efficiency, and compact design. Solid-state lasers employ a solid crystalline or glass medium doped with ions like neodymium or titanium, making them suitable for high-power and high-precision applications. Both laser types serve diverse industrial and scientific purposes but differ significantly in construction, cooling requirements, and operational characteristics.

Fundamental Working Principles

Fiber lasers use a doped optical fiber as the gain medium, where laser light is amplified through stimulated emission within the fiber core, providing high beam quality and efficiency. Solid-state lasers rely on a solid crystalline or glass medium doped with rare-earth or transition metal ions, where excitation occurs via optical pumping to generate laser light. Understanding these fundamental working principles helps you select the right laser type based on power requirements, wavelength, and application specificity.

Key Differences in Laser Construction

Fiber lasers use optical fibers doped with rare-earth elements as the gain medium, enabling compact construction and efficient heat dissipation. Solid-state lasers rely on a solid crystal or glass rod doped with ions like Nd:YAG, requiring more complex cooling systems due to higher thermal load. Your choice depends on application needs, with fiber lasers offering flexibility in beam delivery and solid-state lasers providing high peak power in pulsed modes.

Power Efficiency and Performance Comparison

Fiber lasers demonstrate higher power efficiency compared to solid-state lasers due to their superior thermal management and lower energy consumption. Their performance excels in delivering consistent, high-quality beams with reduced maintenance requirements. If you need reliable, energy-efficient laser solutions, fiber lasers typically offer better long-term operational savings and precision.

Beam Quality and Output Characteristics

Fiber lasers deliver superior beam quality with high brightness and excellent focusability due to their single-mode output and stable beam profile. Solid-state lasers offer variable beam quality depending on the crystal type and cavity design but generally exhibit lower beam brightness compared to fiber lasers. Output characteristics of fiber lasers include higher wall-plug efficiency and longer operational lifetime, whereas solid-state lasers provide higher peak powers suitable for pulsed applications.

Cooling Requirements and Thermal Management

Fiber lasers require less complex cooling systems due to their efficient heat dissipation and smaller thermal load, making them suitable for applications with limited cooling infrastructure. Solid-state lasers generate more heat and typically demand robust cooling methods, such as water or chilled systems, to maintain thermal stability and performance. Understanding the differences in cooling requirements and thermal management can help you select the optimal laser type for your specific industrial or medical application.

Applications in Industry and Research

Fiber lasers excel in telecommunications, medical procedures, and precision cutting due to their high beam quality and energy efficiency. Solid-state lasers dominate in material processing, defense, and scientific research for their high power output and versatility in different wavelengths. Choosing the right laser for your application depends on the specific requirements for power, wavelength, and operational stability.

Cost Considerations and Maintenance

Fiber lasers generally offer lower operational and maintenance costs compared to solid-state lasers due to their higher electrical efficiency and longer component lifespans. Solid-state lasers tend to require more frequent maintenance and replacement of parts such as flash lamps and cooling systems, increasing overall expenses. Initial investment for fiber lasers may be higher, but their reduced downtime and energy consumption result in better cost-effectiveness over time.

Scalability and Integration Potential

Fiber lasers offer superior scalability due to their modular design, allowing easy power scaling and seamless integration into automated industrial systems. Solid-state lasers, while powerful, often face limitations in scaling without significant redesign and may require more complex cooling solutions that hinder straightforward integration. Your choice depends on whether you prioritize flexible scalability with compact integration (fiber lasers) or higher peak power in specific applications (solid-state lasers).

Future Trends in Laser Technology

Fiber lasers dominate the future of laser technology due to their superior efficiency, compact size, and enhanced beam quality, making them ideal for emerging applications in manufacturing and medical fields. Solid-state lasers continue to evolve with advances in crystal materials and cooling techniques, improving power output and pulse control for high-precision tasks. Your choice will increasingly depend on application-specific requirements, as hybrid systems combining fiber and solid-state elements emerge to maximize versatility and performance.

Fiber laser vs Solid-state laser Infographic

libmatt.com

libmatt.com