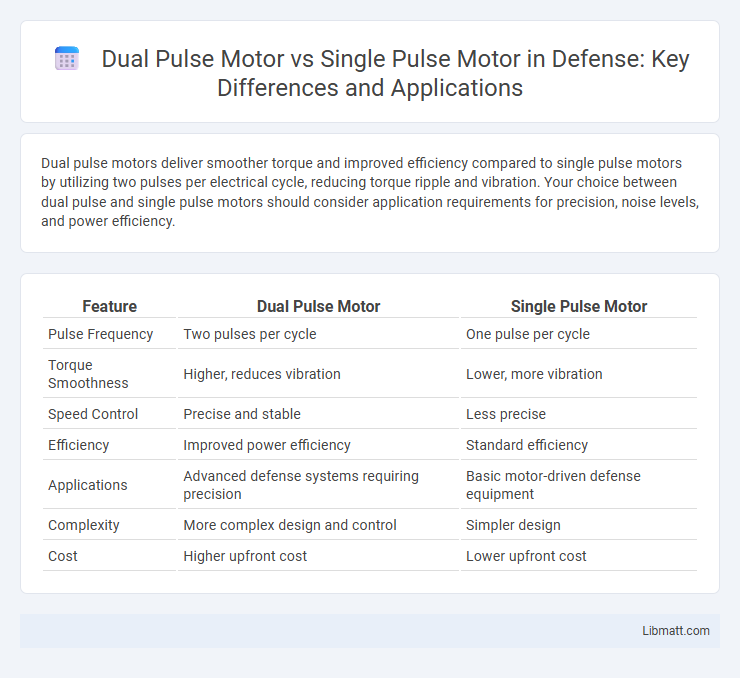

Dual pulse motors deliver smoother torque and improved efficiency compared to single pulse motors by utilizing two pulses per electrical cycle, reducing torque ripple and vibration. Your choice between dual pulse and single pulse motors should consider application requirements for precision, noise levels, and power efficiency.

Table of Comparison

| Feature | Dual Pulse Motor | Single Pulse Motor |

|---|---|---|

| Pulse Frequency | Two pulses per cycle | One pulse per cycle |

| Torque Smoothness | Higher, reduces vibration | Lower, more vibration |

| Speed Control | Precise and stable | Less precise |

| Efficiency | Improved power efficiency | Standard efficiency |

| Applications | Advanced defense systems requiring precision | Basic motor-driven defense equipment |

| Complexity | More complex design and control | Simpler design |

| Cost | Higher upfront cost | Lower upfront cost |

Introduction to Dual Pulse and Single Pulse Motors

Dual pulse motors generate two distinct voltage pulses per cycle, improving torque smoothness and reducing electromagnetic interference compared to single pulse motors, which produce only one voltage pulse per cycle. The dual pulse design enhances motor efficiency and performance by minimizing torque ripple and power losses, making it ideal for precision applications. Your choice between these motors depends on the desired efficiency, noise levels, and operational smoothness required for your specific use case.

Working Principle: Dual Pulse vs Single Pulse Motors

Dual pulse motors operate by delivering two distinct pulses of electrical energy within each switching cycle, enhancing torque output and reducing current ripple compared to single pulse motors, which supply a single electrical pulse per cycle. The dual pulse configuration improves electromagnetic force generation through more frequent energy input, resulting in smoother operation and increased efficiency. Single pulse motors, while simpler in design, often exhibit higher torque ripple and reduced performance under dynamic load conditions due to less frequent energy application.

Key Differences Between Dual Pulse and Single Pulse Motors

Dual pulse motors feature two separate excitation pulses per cycle, resulting in smoother torque and reduced vibration compared to single pulse motors that utilize only one pulse per cycle. The dual pulse design enhances efficiency and motor performance by minimizing current ripple and electromagnetic interference, which are more pronounced in single pulse motors. Your choice between these motor types should consider application requirements for precision, noise levels, and efficiency.

Performance Comparison: Efficiency and Output

Dual pulse motors deliver higher efficiency and improved output compared to single pulse motors by reducing torque ripple and enhancing electromagnetic performance. The dual pulse design enables better power conversion and smoother current flow, resulting in increased motor speed and greater energy savings. Your choice of a dual pulse motor can lead to superior operational stability and more consistent performance in demanding applications.

Applications of Dual Pulse Motors

Dual pulse motors are ideal for applications requiring smoother torque and reduced electromagnetic interference, such as electric vehicles, robotics, and aerospace systems. They enhance performance by utilizing two pulses per electrical cycle, improving efficiency and reducing torque ripple compared to single pulse motors. Your choice of a dual pulse motor can significantly benefit precise control and high-performance scenarios demanding stable and efficient operation.

Applications of Single Pulse Motors

Single pulse motors are commonly used in low-speed applications such as electric fans, small household appliances, and simple mechanical toys, where cost-efficiency and basic control are prioritized. Their simpler winding design provides straightforward operation suitable for devices requiring minimal torque and consistent rotation. These motors excel in applications where precise speed control and high performance are not critical, making them ideal for basic, everyday electrical devices.

Advantages of Dual Pulse Motors

Dual pulse motors offer improved torque performance and smoother operation compared to single pulse motors, resulting in enhanced efficiency and reduced vibrations. Their ability to deliver power in two distinct pulses per cycle allows for better control and higher precision in applications requiring fine motor control. You can benefit from increased reliability and longer motor lifespan due to the balanced load distribution inherent in dual pulse designs.

Advantages of Single Pulse Motors

Single pulse motors offer simpler construction and easier control, resulting in lower manufacturing and maintenance costs compared to dual pulse motors. They produce less electromagnetic interference, enhancing the reliability of sensitive electronic systems. The single pulse design provides smoother torque output at low speeds, making them ideal for applications requiring precise motion control.

Challenges and Limitations of Each Motor Type

Dual pulse motors face challenges in complexity and cost due to their advanced control systems and the requirement for precise synchronization between pulses. Single pulse motors are limited by lower efficiency and increased vibration because they generate torque during only one pulse per cycle, resulting in less smooth operation. Both motor types encounter thermal management issues, but dual pulse motors often require more sophisticated cooling solutions to handle higher power densities.

Choosing the Right Motor: Factors to Consider

When selecting between a dual pulse motor and a single pulse motor, consider factors such as torque requirements, speed control precision, and application-specific load characteristics. Dual pulse motors offer smoother torque output and reduced vibration, making them ideal for high-performance and precision-driven tasks, while single pulse motors are often more cost-effective and suitable for simpler applications with lower dynamic demands. Efficiency, control complexity, and maintenance needs also play critical roles in determining the best motor type for your specific industrial or commercial use case.

dual pulse motor vs single pulse motor Infographic

libmatt.com

libmatt.com