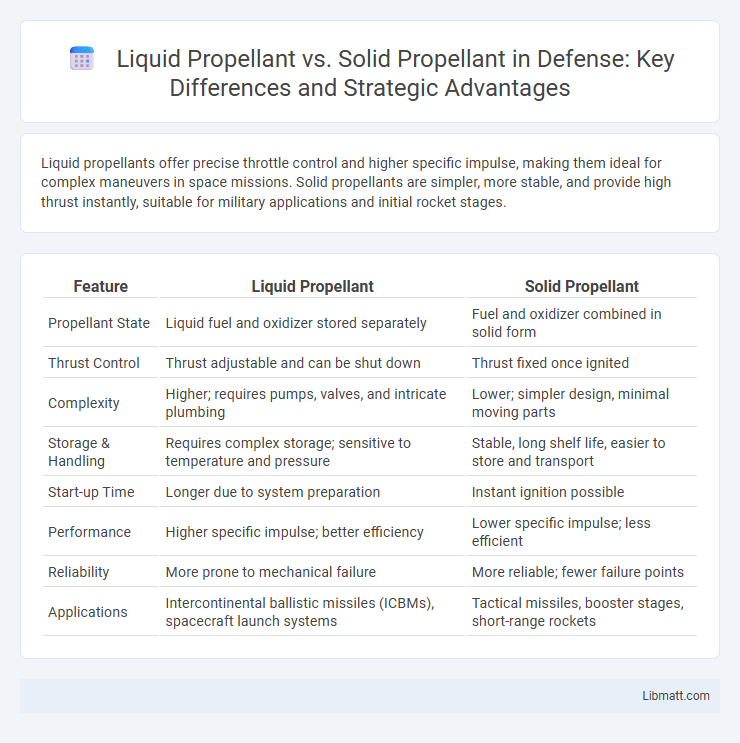

Liquid propellants offer precise throttle control and higher specific impulse, making them ideal for complex maneuvers in space missions. Solid propellants are simpler, more stable, and provide high thrust instantly, suitable for military applications and initial rocket stages.

Table of Comparison

| Feature | Liquid Propellant | Solid Propellant |

|---|---|---|

| Propellant State | Liquid fuel and oxidizer stored separately | Fuel and oxidizer combined in solid form |

| Thrust Control | Thrust adjustable and can be shut down | Thrust fixed once ignited |

| Complexity | Higher; requires pumps, valves, and intricate plumbing | Lower; simpler design, minimal moving parts |

| Storage & Handling | Requires complex storage; sensitive to temperature and pressure | Stable, long shelf life, easier to store and transport |

| Start-up Time | Longer due to system preparation | Instant ignition possible |

| Performance | Higher specific impulse; better efficiency | Lower specific impulse; less efficient |

| Reliability | More prone to mechanical failure | More reliable; fewer failure points |

| Applications | Intercontinental ballistic missiles (ICBMs), spacecraft launch systems | Tactical missiles, booster stages, short-range rockets |

Introduction to Rocket Propellants

Liquid propellants consist of separate fuel and oxidizer components stored in liquid form, offering precise thrust control and higher specific impulse for efficient rocket propulsion. Solid propellants combine fuel and oxidizer into a single, stable composite material, providing simplicity, reliability, and ease of storage with rapid ignition capabilities. The choice between liquid and solid propellants depends on mission requirements, balancing factors like performance, controllability, weight, and cost in rocket engine design.

What Are Liquid Propellants?

Liquid propellants are fuels and oxidizers stored separately in liquid form, combined in a combustion chamber to produce thrust. They offer precise thrust control and higher specific impulse compared to solid propellants, making them ideal for complex mission profiles. Common examples include liquid oxygen (LOX) paired with liquid hydrogen or RP-1 kerosene, widely used in rockets like the Space Shuttle and Falcon 9.

Overview of Solid Propellants

Solid propellants consist of a homogeneous mixture of fuel and oxidizer in a solid state, providing a stable and reliable source of thrust with minimal mechanical complexity. They are widely used in military missiles, fireworks, and space launch boosters due to their ease of storage and rapid ignition capabilities. Your choice of solid propellant ensures consistent performance under varying environmental conditions, making it ideal for applications demanding simplicity and high thrust output.

Key Differences: Liquid vs Solid Propellant

Liquid propellants offer higher specific impulse and controllable thrust, making them ideal for precise orbital maneuvers and long-duration missions, while solid propellants provide simplicity, reliability, and quick ignition suitable for military missiles and booster stages. Liquid propellant engines use separate tanks for fuel and oxidizer, enabling throttle control and restart capability, whereas solid propellant motors have a pre-mixed combustible grain that cannot be throttled or shut down once ignited. The storage and handling requirements differ significantly, as liquid propellants often require cryogenic or hypergolic materials with complex plumbing, contrasting with the stable, storable nature of solid propellant grains.

Performance and Efficiency Comparison

Liquid propellants offer higher specific impulse and better throttle control compared to solid propellants, enabling more efficient fuel usage and precise maneuvering in rockets. Solid propellants provide simplicity and reliability with rapid ignition, but typically deliver lower performance due to fixed thrust and less optimal combustion. Your choice depends on mission needs, with liquid systems favored for high-efficiency orbital missions and solid systems preferred for cost-effective, short-duration launches.

Storage and Handling Requirements

Liquid propellants require complex storage systems with insulated, cryogenic tanks and specialized handling equipment to manage their volatile and often corrosive nature. Solid propellants offer simplified storage and handling since they are stable at ambient conditions and do not require pressurized containment, reducing logistical constraints. Safety protocols for liquid propellants are stringent due to their toxicity and flammability, while solid propellant storage emphasizes protection from mechanical shocks and temperature extremes.

Safety Considerations

Liquid propellants require meticulous handling and storage due to their volatile and often toxic nature, posing higher risks of leaks and explosions. Solid propellants offer greater stability and are less sensitive to physical shocks, making them safer to store and transport. Your choice should consider the specific mission requirements alongside these safety profiles to ensure operational security.

Cost Analysis: Liquid vs Solid

Liquid propellant systems generally incur higher initial costs due to complex storage, handling infrastructure, and precision engineering requirements, while solid propellant systems benefit from simpler design and manufacturing processes, resulting in lower production costs. Operational expenses for liquid propellants often increase because of maintenance, fueling procedures, and safety measures, whereas solid propellants demand less operational expenditure but lack restart capability and flexibility. Economically, solid propellants provide cost-effective solutions for short-term or disposable applications, whereas liquid propellants, despite higher costs, offer better performance and reusability for long-term missions.

Applications in Space and Defense

Liquid propellants offer precise thrust control and restart capability, making them ideal for orbital maneuvering, deep space missions, and advanced missile systems in both space and defense sectors. Solid propellants provide high thrust-to-weight ratios and long shelf life, commonly used in military rockets, boosters, and reliable launch vehicles where quick response and simplicity are critical. The choice between liquid and solid propellants depends on mission requirements such as duration, control precision, and storage conditions in aerospace and defense applications.

Future Trends in Propulsion Technology

Liquid propellant propulsion systems offer superior control and efficiency, driving future trends in reusable rocket technology and deep space exploration. Advances in green liquid propellants and hybrid systems aim to reduce environmental impact while enhancing performance for extended missions. Your choice of propulsion technology will increasingly depend on mission requirements, balancing thrust precision and cost-effectiveness in evolving aerospace landscapes.

liquid propellant vs solid propellant Infographic

libmatt.com

libmatt.com