Longwave infrared (LWIR) radiation typically ranges from 8 to 15 microns, making it ideal for thermal imaging in low-light or no-light environments since it detects heat emitted by objects. Midwave infrared (MWIR) spans approximately 3 to 5 microns and offers higher resolution and sensitivity, especially useful for detecting temperature differences and chemical signatures in applications like missile targeting and gas detection.

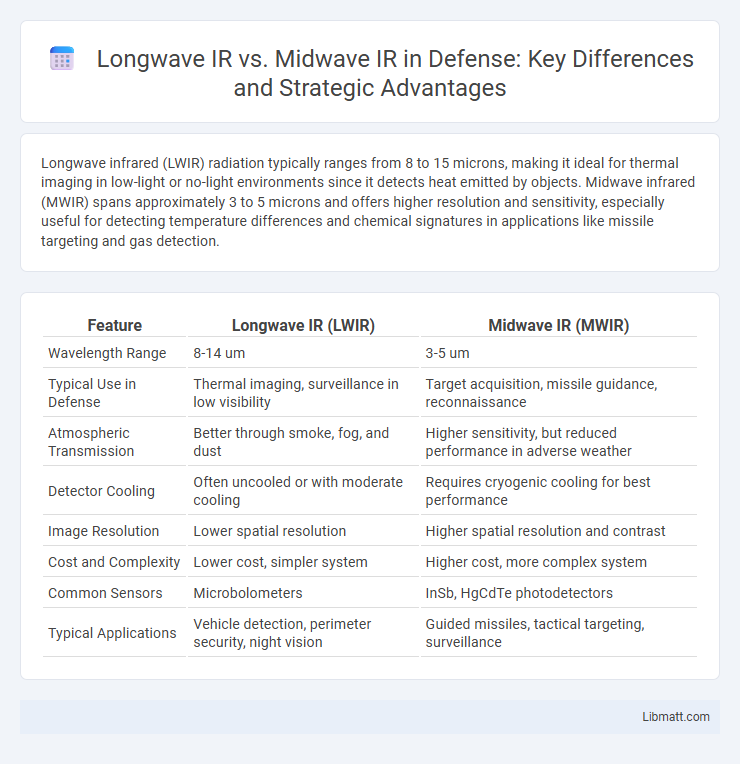

Table of Comparison

| Feature | Longwave IR (LWIR) | Midwave IR (MWIR) |

|---|---|---|

| Wavelength Range | 8-14 um | 3-5 um |

| Typical Use in Defense | Thermal imaging, surveillance in low visibility | Target acquisition, missile guidance, reconnaissance |

| Atmospheric Transmission | Better through smoke, fog, and dust | Higher sensitivity, but reduced performance in adverse weather |

| Detector Cooling | Often uncooled or with moderate cooling | Requires cryogenic cooling for best performance |

| Image Resolution | Lower spatial resolution | Higher spatial resolution and contrast |

| Cost and Complexity | Lower cost, simpler system | Higher cost, more complex system |

| Common Sensors | Microbolometers | InSb, HgCdTe photodetectors |

| Typical Applications | Vehicle detection, perimeter security, night vision | Guided missiles, tactical targeting, surveillance |

Understanding Infrared: Midwave vs. Longwave

Longwave infrared (LWIR) typically covers wavelengths from 8 to 14 micrometers, making it highly effective for thermal imaging in environments with obstacles like smoke or fog, as it captures emitted heat from objects. Midwave infrared (MWIR) ranges from 3 to 5 micrometers and excels at detecting temperature differences with greater sensitivity, often used in military and industrial applications for detailed thermal analysis. Your choice between LWIR and MWIR depends on factors like atmospheric conditions, target temperature range, and specific imaging requirements.

Spectral Ranges: MWIR and LWIR Explained

Midwave infrared (MWIR) typically covers the spectral range of 3 to 5 micrometers, while longwave infrared (LWIR) spans from 8 to 14 micrometers. MWIR sensors provide higher spatial resolution and are ideal for detecting hot objects due to their sensitivity to thermal emissions from targets at moderate temperatures. LWIR, with its longer wavelengths, excels in detecting cooler objects and penetrates smoke, dust, and atmospheric obscurants more effectively, making it crucial for applications in thermal imaging and night vision.

Key Differences Between MWIR and LWIR

Midwave infrared (MWIR) operates in the 3-5 micron wavelength range, offering superior resolution and sensitivity for detecting heat signatures in moderate temperature environments, whereas longwave infrared (LWIR) covers the 8-14 micron range, excelling in thermal imaging through obscurants like smoke and fog. MWIR sensors provide faster response times and better contrast for high-temperature targets, while LWIR sensors are more effective for general thermal detection and passive imaging in varied conditions. Choosing between MWIR and LWIR depends on Your specific application needs, including target temperature, atmospheric conditions, and required imaging clarity.

Applications of Midwave Infrared (MWIR)

Midwave Infrared (MWIR) wavelengths ranging from 3 to 5 microns are extensively used in thermal imaging for military targeting, environmental monitoring, and industrial inspection due to their superior sensitivity to heat signatures and atmospheric transmission properties. MWIR sensors excel in detecting hot objects at moderate distances, making them ideal for surveillance, missile guidance, and gas detection applications. Your analysis will benefit from MWIR's ability to provide high-resolution images in variable weather conditions where other infrared bands, such as Longwave IR, may be less effective.

Uses and Benefits of Longwave Infrared (LWIR)

Longwave Infrared (LWIR) operates in the 8-14 micron wavelength range, making it highly effective for thermal imaging in low-visibility conditions such as fog, smoke, and darkness, commonly used in night vision, firefighting, and surveillance. LWIR sensors detect heat emissions directly from objects, providing temperature measurements without external illumination, which benefits environmental monitoring, industrial inspection, and medical diagnostics. The longer wavelength of LWIR offers better penetration through atmospheric obscurants compared to Midwave Infrared (MWIR), enhancing its reliability and accuracy in real-world applications.

Image Quality: MWIR vs. LWIR Performance

Midwave IR (MWIR) sensors typically offer higher image resolution and greater sensitivity to temperature differences compared to Longwave IR (LWIR) sensors, resulting in clearer and more detailed thermal images. MWIR operates in the 3-5 micrometer wavelength range, which provides better contrast and image quality in environments with moderate temperatures and less atmospheric interference. LWIR, operating in the 8-14 micrometer range, excels in detecting cooler objects and performs better in smoky, dusty, or foggy conditions but generally produces lower resolution images than MWIR.

Environmental Factors: Sensitivity and Penetration

Longwave infrared (LWIR) radiation, typically ranging from 8 to 15 micrometers, exhibits higher sensitivity to thermal emissions and better penetration through atmospheric conditions like smoke, fog, and dust compared to midwave infrared (MWIR) radiation, which spans 3 to 5 micrometers. MWIR sensors offer superior resolution and detection of temperature differences but are more affected by water vapor absorption and other environmental interferences. The choice between LWIR and MWIR depends on specific environmental factors, with LWIR favored for operations in challenging weather for consistent thermal imaging performance.

Detector Technologies: MWIR vs. LWIR Sensors

Midwave infrared (MWIR) sensors typically use InSb (indium antimonide) or HgCdTe (mercury cadmium telluride) detector technologies, offering high sensitivity and rapid response for wavelengths between 3 to 5 micrometers, suitable for hot target detection and high-resolution imaging. Longwave infrared (LWIR) detectors primarily utilize uncooled microbolometers or cooled HgCdTe sensors, optimized for the 8 to 14 micrometer range, providing effective thermal imaging in cooler environments with greater atmospheric transmission. MWIR sensors generally require cryogenic cooling to maintain performance, whereas LWIR microbolometers operate efficiently at ambient temperatures, influencing sensor selection based on application-specific thermal contrast and operational conditions.

Cost Considerations: MWIR and LWIR Systems

Midwave IR (MWIR) systems typically have higher costs due to the complexity of cooling mechanisms and the use of more expensive detector materials like InSb or HgCdTe. Longwave IR (LWIR) systems often employ uncooled microbolometer detectors, which reduces overall expenses and maintenance needs, making them more cost-effective for many applications. Your choice between MWIR and LWIR should balance budget constraints with performance requirements, as MWIR provides better image clarity and target discrimination but at increased cost.

Choosing Between MWIR and LWIR: Which Suits Your Needs?

Midwave infrared (MWIR) operates within the 3-5 micron wavelength range, offering superior resolution and clarity ideal for applications requiring precise thermal imaging, such as targeting or chemical detection. Longwave infrared (LWIR), spanning 8-14 microns, excels in detecting temperature differences at longer distances and through environmental obscurants like smoke or fog, making it suitable for surveillance and general thermal monitoring. Your choice between MWIR and LWIR depends on factors like imaging environment, range requirements, and sensitivity to atmospheric conditions.

longwave IR vs midwave IR Infographic

libmatt.com

libmatt.com