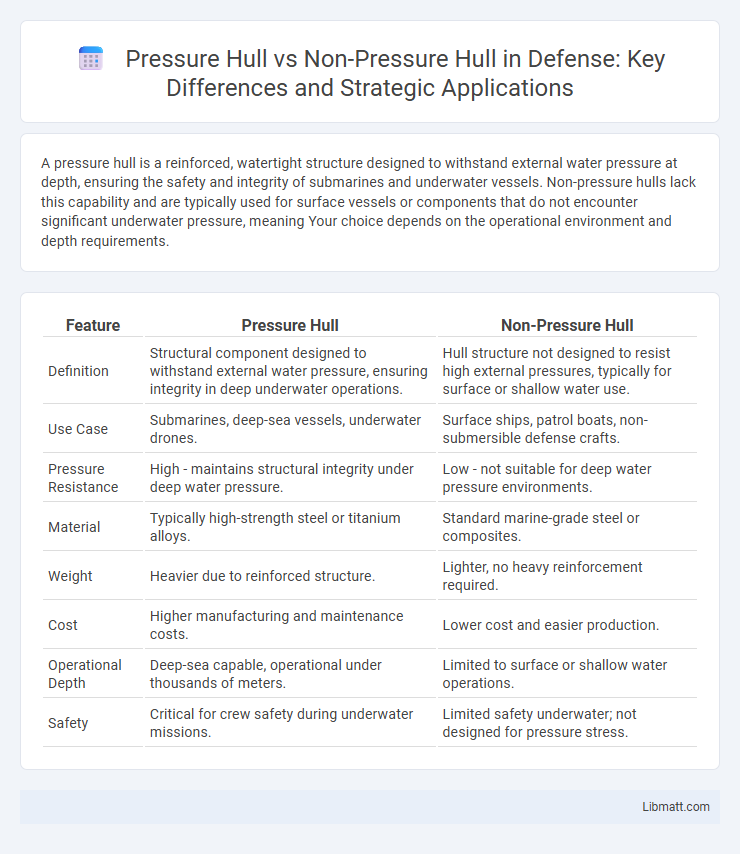

A pressure hull is a reinforced, watertight structure designed to withstand external water pressure at depth, ensuring the safety and integrity of submarines and underwater vessels. Non-pressure hulls lack this capability and are typically used for surface vessels or components that do not encounter significant underwater pressure, meaning Your choice depends on the operational environment and depth requirements.

Table of Comparison

| Feature | Pressure Hull | Non-Pressure Hull |

|---|---|---|

| Definition | Structural component designed to withstand external water pressure, ensuring integrity in deep underwater operations. | Hull structure not designed to resist high external pressures, typically for surface or shallow water use. |

| Use Case | Submarines, deep-sea vessels, underwater drones. | Surface ships, patrol boats, non-submersible defense crafts. |

| Pressure Resistance | High - maintains structural integrity under deep water pressure. | Low - not suitable for deep water pressure environments. |

| Material | Typically high-strength steel or titanium alloys. | Standard marine-grade steel or composites. |

| Weight | Heavier due to reinforced structure. | Lighter, no heavy reinforcement required. |

| Cost | Higher manufacturing and maintenance costs. | Lower cost and easier production. |

| Operational Depth | Deep-sea capable, operational under thousands of meters. | Limited to surface or shallow water operations. |

| Safety | Critical for crew safety during underwater missions. | Limited safety underwater; not designed for pressure stress. |

Introduction to Pressure Hulls and Non-Pressure Hulls

Pressure hulls are specially designed structural components of submarines and underwater vessels that withstand external water pressure while maintaining internal atmospheric pressure for crew safety. In contrast, non-pressure hulls, often referred to as outer hulls or light hulls, do not bear significant pressure loads but provide hydrodynamic shape and protection from the environment. The distinction between pressure hulls and non-pressure hulls is critical in submarine engineering to ensure operational integrity and crew survivability at varying depths.

Definition and Core Functions

A pressure hull is the reinforced inner structure of a submarine or underwater vehicle designed to withstand external water pressure and protect occupants from crushing depths. Non-pressure hulls serve as external coverings or structural components that do not resist pressure but provide hydrodynamic shape, insulation, and protection for equipment. Understanding the distinction between pressure and non-pressure hulls helps ensure Your vessel's safety and operational integrity in deep-sea environments.

Structural Differences

Pressure hulls are designed with thick, high-strength steel or titanium to withstand extreme underwater pressures, maintaining a cylindrical or spherical shape to evenly distribute stress. Non-pressure hulls often use lighter materials and simpler flat or angular shapes, as they are not engineered to resist deep-sea pressure but rather to provide structural support and buoyancy. The overall structural design of pressure hulls prioritizes maximum endurance against collapse, while non-pressure hulls emphasize flexibility and integration with other vessel components.

Materials Used in Construction

Pressure hulls are typically constructed from high-strength materials such as HY-80 or HY-100 steel alloys, titanium, and reinforced composites to withstand extreme underwater pressure and ensure structural integrity. Non-pressure hulls use lighter materials like aluminum or fiberglass, which provide durability and corrosion resistance but are not designed to endure significant pressure. The choice of materials directly impacts the vessel's depth rating, safety, and performance in submersion scenarios.

Applications in Marine Engineering

Pressure hulls are critical in deep-sea submersibles and submarines, designed to withstand high external water pressure and ensure structural integrity at extreme depths. Non-pressure hulls, commonly found in surface vessels and some underwater vehicles, provide buoyancy and protect internal components without being structurally robust against deep-water pressure. Marine engineering applications differentiate these hull types based on operational depth, safety requirements, and mission-specific durability standards.

Pressure Resistance Capabilities

Pressure hulls are engineered with robust, thick materials such as high-grade steel or titanium, enabling them to withstand extreme underwater pressures encountered at great depths, often exceeding several hundred atmospheres. Non-pressure hulls lack this reinforced structure and are designed mainly for surface or shallow water operations, making them vulnerable to deformation or collapse under high pressure. The pressure resistance capabilities of pressure hulls are critical for deep-sea submersibles and submarines, ensuring integrity and safety during prolonged exposure to intense underwater forces.

Safety Considerations and Standards

Pressure hulls are engineered to withstand external water pressure at depth, meeting stringent safety standards such as ABS Rules for Submersibles and ISO 13628, ensuring structural integrity in extreme underwater environments. Non-pressure hulls, often used in shallow water or surface vessels, lack the robust certification requirements, resulting in limited protection against pressure-induced failures. Adherence to rigorous inspection protocols and material certifications is critical for pressure hulls to prevent catastrophic failure, while non-pressure hull designs emphasize resistance to environmental and operational stresses without pressure containment.

Maintenance and Lifecycle

Pressure hulls require rigorous maintenance protocols to withstand high external pressures and prevent structural fatigue, extending their operational lifecycle often beyond 30 years with periodic inspections and repairs. Non-pressure hulls, typically designed for shallower environments, have less demanding maintenance schedules but generally experience shorter lifecycles due to increased exposure to corrosion and mechanical wear. Effective maintenance strategies for pressure hulls focus on crack detection and material integrity, whereas non-pressure hull upkeep prioritizes surface treatment and corrosion control to maximize service life.

Cost Implications

Pressure hulls require specialized materials and manufacturing processes, significantly increasing production costs compared to non-pressure hulls. Maintenance and inspection expenses also rise due to the rigorous safety standards needed for withstanding high-pressure environments. Non-pressure hulls offer cost advantages by using simpler construction techniques and materials but are limited in depth performance and operational capability.

Future Trends and Innovations

Future trends in pressure hull design emphasize advanced composite materials and additive manufacturing techniques to enhance strength-to-weight ratios and corrosion resistance. Innovations in non-pressure hull structures focus on modular and flexible frameworks utilizing carbon fiber and smart materials for improved adaptability and durability. Both hull types benefit from integrated sensor networks and AI-driven monitoring systems to optimize safety and performance in increasingly demanding underwater missions.

pressure hull vs non-pressure hull Infographic

libmatt.com

libmatt.com