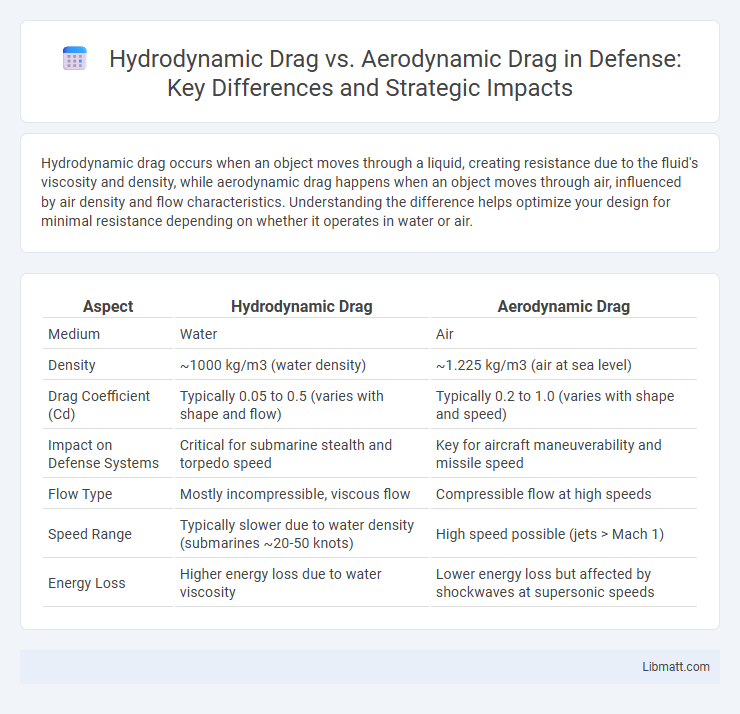

Hydrodynamic drag occurs when an object moves through a liquid, creating resistance due to the fluid's viscosity and density, while aerodynamic drag happens when an object moves through air, influenced by air density and flow characteristics. Understanding the difference helps optimize your design for minimal resistance depending on whether it operates in water or air.

Table of Comparison

| Aspect | Hydrodynamic Drag | Aerodynamic Drag |

|---|---|---|

| Medium | Water | Air |

| Density | ~1000 kg/m3 (water density) | ~1.225 kg/m3 (air at sea level) |

| Drag Coefficient (Cd) | Typically 0.05 to 0.5 (varies with shape and flow) | Typically 0.2 to 1.0 (varies with shape and speed) |

| Impact on Defense Systems | Critical for submarine stealth and torpedo speed | Key for aircraft maneuverability and missile speed |

| Flow Type | Mostly incompressible, viscous flow | Compressible flow at high speeds |

| Speed Range | Typically slower due to water density (submarines ~20-50 knots) | High speed possible (jets > Mach 1) |

| Energy Loss | Higher energy loss due to water viscosity | Lower energy loss but affected by shockwaves at supersonic speeds |

Introduction to Hydrodynamic and Aerodynamic Drag

Hydrodynamic drag refers to the resistance experienced by objects moving through a liquid, primarily influenced by fluid density, viscosity, and flow velocity, whereas aerodynamic drag occurs as objects move through gases like air, affected by air density, shape, and surface roughness. Both types of drag comprise pressure drag and friction drag, but hydrodynamic drag generally involves higher fluid density, leading to greater resistance for submerged bodies compared to aerodynamic drag on vehicles or aircraft. Understanding the fundamental differences between hydrodynamic and aerodynamic drag is crucial for optimizing performance in marine vessels, aircraft, and automotive designs.

Understanding the Science of Drag Forces

Hydrodynamic drag occurs when an object moves through a liquid, such as water, while aerodynamic drag happens when an object moves through a gas, such as air. The density and viscosity of the fluid significantly influence the magnitude of these drag forces, with water generating higher resistance due to its greater density compared to air. Understanding these differences can help you optimize designs for ships, submarines, or aircraft by minimizing drag and improving performance.

Key Differences Between Hydrodynamic and Aerodynamic Drag

Hydrodynamic drag occurs when an object moves through water, which is denser and more viscous than air, causing greater resistance compared to aerodynamic drag experienced in air. The key differences lie in fluid properties: water's higher density results in stronger drag forces and more energy consumption, while air's lower density allows for faster speeds with less drag. Understanding these distinctions helps optimize designs in maritime and aerospace applications, improving efficiency for your vehicle or vessel.

Factors Affecting Hydrodynamic Drag

Hydrodynamic drag is influenced by fluid density, velocity of the object in water, surface roughness, and shape of the submerged body, which determine resistance experienced during motion. The viscosity of water and turbulence in the boundary layer also play crucial roles in increasing drag force. Understanding these factors can help optimize your vessel's design to minimize energy loss and improve overall performance.

Influences on Aerodynamic Drag

Aerodynamic drag is primarily influenced by factors such as air density, object shape, surface roughness, and velocity relative to the air. Streamlined shapes reduce pressure drag by allowing smoother airflow, while surface roughness increases skin friction drag. Changes in altitude and temperature affect air density, which directly impacts the magnitude of aerodynamic drag on vehicles and aircraft.

Mathematical Models of Drag Forces

Mathematical models of hydrodynamic drag typically use quadratic drag equations dependent on fluid density, object's velocity, and drag coefficient, often expressed as F_d = 1/2 r v2 C_d A, where r represents water density, v is velocity, C_d is the drag coefficient, and A is the reference area. Aerodynamic drag models share a similar quadratic structure but incorporate air density instead, reflecting the differences in fluid properties between air and water, which directly influence drag force calculations. Computational fluid dynamics (CFD) and empirical correlations refine these models by accounting for complex flow characteristics such as turbulence, boundary layer effects, and Reynolds number variations in both hydrodynamic and aerodynamic contexts.

Real-World Applications: Hydrodynamic vs. Aerodynamic Drag

Hydrodynamic drag significantly impacts the performance and fuel efficiency of ships, submarines, and underwater vehicles by resisting their motion through water, which is denser and more viscous than air. Aerodynamic drag is crucial in automotive, aerospace, and sports industries, where optimizing vehicle shapes and surfaces reduces air resistance to enhance speed and energy efficiency. Engineers apply computational fluid dynamics (CFD) and wind tunnel testing to minimize both drag types, tailoring design strategies according to fluid properties and operational environments.

Methods to Reduce Drag in Water and Air

Methods to reduce hydrodynamic drag in water primarily involve streamlining hull shapes, applying smooth coatings like antifouling paints, and optimizing appendages to minimize turbulence and flow separation. Aerodynamic drag reduction techniques focus on refining vehicle contours for laminar airflow, using aerodynamic aids such as spoilers and vortex generators, and selecting low-drag materials to decrease surface roughness. Implementing these methods can enhance your vessel or vehicle performance by improving efficiency and reducing energy consumption in both air and water environments.

Comparative Analysis: Efficiency and Energy Consumption

Hydrodynamic drag in water is significantly higher than aerodynamic drag in air due to the greater density and viscosity of water, resulting in increased resistance and energy consumption for propulsion. Efficiency in vehicles like ships and submarines is often limited by this drag, requiring specialized hull designs to minimize energy loss, whereas aircraft benefit from streamlined shapes that reduce aerodynamic drag to enhance fuel efficiency. Comparative studies show that managing hydrodynamic drag demands more power input relative to aerodynamic drag for achieving comparable speeds, impacting overall operational costs and sustainability in marine versus aerial transportation.

Future Trends in Drag Reduction Technologies

Future trends in drag reduction technologies emphasize advanced materials such as graphene-enhanced composites for aerodynamic surfaces and superhydrophobic coatings to minimize hydrodynamic drag in marine vessels. Active flow control techniques using smart sensors and machine learning algorithms optimize fluid dynamics in real-time to reduce turbulence and vortex formation. Integration of biomimetic designs inspired by shark skin and bird feathers shows promise for enhancing efficiency in both air and water transport.

hydrodynamic drag vs aerodynamic drag Infographic

libmatt.com

libmatt.com