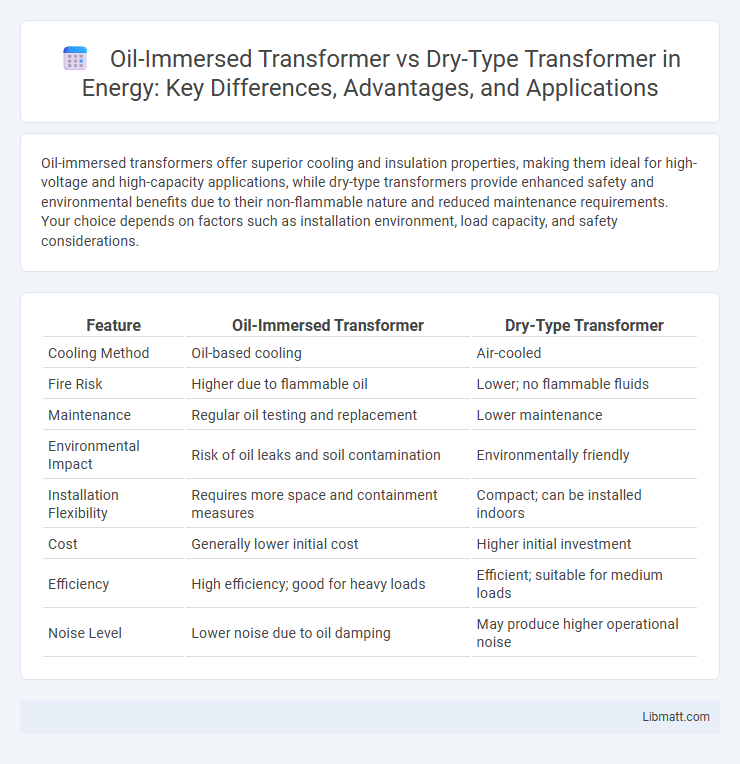

Oil-immersed transformers offer superior cooling and insulation properties, making them ideal for high-voltage and high-capacity applications, while dry-type transformers provide enhanced safety and environmental benefits due to their non-flammable nature and reduced maintenance requirements. Your choice depends on factors such as installation environment, load capacity, and safety considerations.

Table of Comparison

| Feature | Oil-Immersed Transformer | Dry-Type Transformer |

|---|---|---|

| Cooling Method | Oil-based cooling | Air-cooled |

| Fire Risk | Higher due to flammable oil | Lower; no flammable fluids |

| Maintenance | Regular oil testing and replacement | Lower maintenance |

| Environmental Impact | Risk of oil leaks and soil contamination | Environmentally friendly |

| Installation Flexibility | Requires more space and containment measures | Compact; can be installed indoors |

| Cost | Generally lower initial cost | Higher initial investment |

| Efficiency | High efficiency; good for heavy loads | Efficient; suitable for medium loads |

| Noise Level | Lower noise due to oil damping | May produce higher operational noise |

Introduction to Oil-Immersed and Dry-Type Transformers

Oil-immersed transformers use mineral or synthetic oil for insulation and cooling, enhancing heat dissipation and extending transformer lifespan. Dry-type transformers rely on air or epoxy resin insulation, providing safer operation in indoor or environmentally sensitive areas due to the absence of flammable oil. Both types serve critical roles in electrical power distribution, with oil-immersed models preferred for high voltage and high capacity applications, while dry-type transformers excel in low to medium voltage settings requiring reduced maintenance and fire risk.

Basic Operating Principles

Oil-immersed transformers use mineral oil to insulate and cool the core and windings, enabling efficient heat dissipation during electrical energy transfer. Dry-type transformers rely on air or resin encapsulation for insulation and cooling, eliminating the need for liquid coolants but requiring robust ventilation systems. Both operate on electromagnetic induction principles, converting voltage levels while maintaining energy integrity through magnetic flux in the core.

Design and Construction Differences

Oil-immersed transformers use mineral oil or synthetic oil for cooling and insulation, featuring sealed metal tanks that enhance heat dissipation and protect internal components from moisture. Dry-type transformers rely on air or epoxy resin for insulation, often incorporating cast resin windings and ventilated enclosures to maintain temperature without liquid coolant. The design of oil-immersed transformers supports higher power ratings and better thermal management, while dry-type transformers emphasize safety in indoor and environmentally sensitive applications.

Cooling Methods Compared

Oil-immersed transformers utilize mineral oil or synthetic oil as a coolant to efficiently dissipate heat through natural or forced circulation, providing superior thermal insulation and cooling performance. Dry-type transformers rely on air cooling, either natural or forced, which limits their cooling capacity but reduces fire risk and environmental concerns associated with oil leaks. Choosing between these cooling methods depends on your installation requirements, with oil-immersed transformers favored for high-capacity, outdoor applications and dry-type transformers preferred for indoor or environmentally sensitive locations.

Efficiency and Performance

Oil-immersed transformers generally offer higher efficiency and better performance under heavy load conditions due to their superior cooling capabilities, which reduce energy losses and extend transformer lifespan. Dry-type transformers provide reliable performance with lower maintenance and enhanced safety in environments sensitive to fire hazards, though they typically exhibit slightly lower efficiency compared to oil-cooled models. Your choice depends on balancing efficiency needs with operational environment and safety requirements.

Safety and Fire Risk Considerations

Oil-immersed transformers contain mineral oil that provides excellent cooling but poses a higher fire risk due to flammability, requiring stringent safety measures and fire protection systems. Dry-type transformers use air or epoxy resin insulation, significantly reducing fire hazards and making them suitable for indoor or densely populated areas. Your choice should consider these safety factors to minimize fire risks and ensure compliance with local regulations.

Installation and Maintenance Requirements

Oil-immersed transformers require careful installation with considerations for oil containment and fire safety, alongside regular oil testing and maintenance to detect leaks or degradation. Dry-type transformers offer easier installation with less space and no need for oil handling, reducing fire risk and simplifying routine inspections and cleaning. Your choice impacts ongoing maintenance costs and installation complexity depending on the environment and safety regulations.

Environmental Impact and Sustainability

Oil-immersed transformers contain mineral oil that poses risks of leaks and soil contamination, necessitating careful handling and disposal to minimize environmental impact. Dry-type transformers use air or epoxy insulation, significantly reducing fire hazards and eliminating the risk of oil spills, making them more sustainable in sensitive environments. The trend toward dry-type transformers aligns with stricter environmental regulations and sustainability goals in power distribution and industrial applications.

Cost Analysis and Lifespan

Oil-immersed transformers typically have lower initial costs compared to dry-type transformers due to simpler cooling systems and materials, but they require regular maintenance and oil monitoring, impacting long-term expenses. Dry-type transformers cost more upfront because of their advanced insulation and cooling technologies, yet they offer longer lifespans with reduced maintenance needs, especially in environments sensitive to fire or contamination. The overall cost-effectiveness depends on factors such as operational environment, safety requirements, and maintenance capabilities, with oil-immersed units favored in heavy industrial settings and dry-type preferred in indoor or environmentally sensitive locations.

Ideal Applications and Use Cases

Oil-immersed transformers excel in heavy industrial environments and outdoor installations due to their superior cooling and higher power capacity, making them ideal for power generation plants and large commercial facilities. Dry-type transformers suit indoor applications such as hospitals, schools, and office buildings where fire safety, low maintenance, and quieter operation are critical. Choosing your transformer based on the installation environment and regulatory requirements ensures optimal performance and safety.

Oil-immersed transformer vs Dry-type transformer Infographic

libmatt.com

libmatt.com