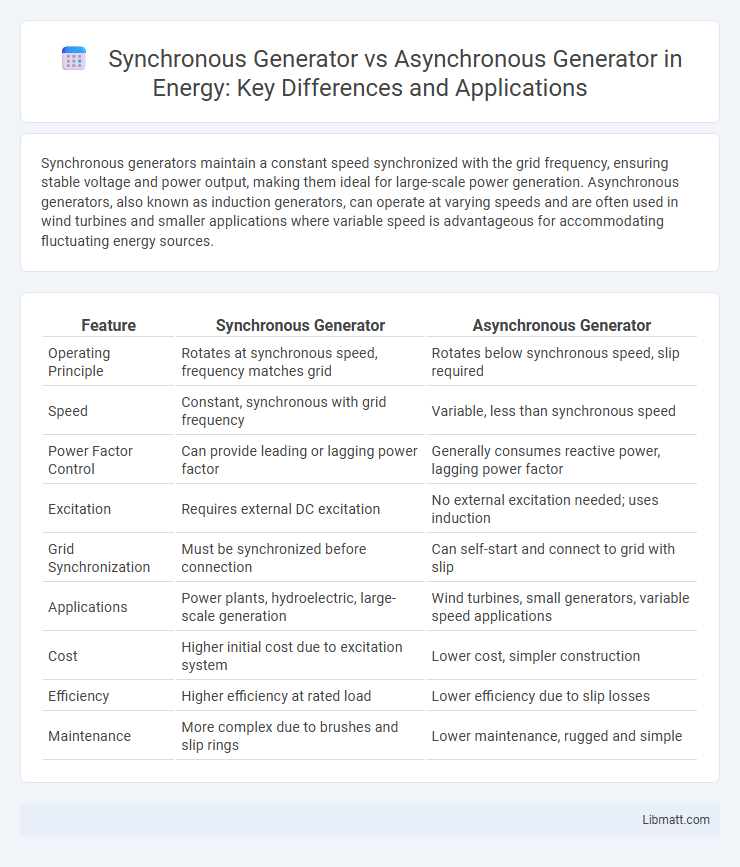

Synchronous generators maintain a constant speed synchronized with the grid frequency, ensuring stable voltage and power output, making them ideal for large-scale power generation. Asynchronous generators, also known as induction generators, can operate at varying speeds and are often used in wind turbines and smaller applications where variable speed is advantageous for accommodating fluctuating energy sources.

Table of Comparison

| Feature | Synchronous Generator | Asynchronous Generator |

|---|---|---|

| Operating Principle | Rotates at synchronous speed, frequency matches grid | Rotates below synchronous speed, slip required |

| Speed | Constant, synchronous with grid frequency | Variable, less than synchronous speed |

| Power Factor Control | Can provide leading or lagging power factor | Generally consumes reactive power, lagging power factor |

| Excitation | Requires external DC excitation | No external excitation needed; uses induction |

| Grid Synchronization | Must be synchronized before connection | Can self-start and connect to grid with slip |

| Applications | Power plants, hydroelectric, large-scale generation | Wind turbines, small generators, variable speed applications |

| Cost | Higher initial cost due to excitation system | Lower cost, simpler construction |

| Efficiency | Higher efficiency at rated load | Lower efficiency due to slip losses |

| Maintenance | More complex due to brushes and slip rings | Lower maintenance, rugged and simple |

Introduction to Synchronous and Asynchronous Generators

Synchronous generators operate with a rotor speed synchronized to the grid frequency, enabling precise control over voltage and power output, commonly used in power plants for stable electricity generation. Asynchronous generators, or induction generators, run at a speed slightly different from the grid frequency, often utilized in wind turbines due to their robustness and simpler design. Both types serve distinct roles in electrical systems, with synchronous models favored for grid stability and asynchronous models valued for cost-effectiveness and mechanical simplicity.

Basic Working Principles

Synchronous generators operate by rotating a magnetic field at the same speed as the electrical grid frequency, ensuring a constant and stable output voltage. In contrast, asynchronous generators, also known as induction generators, produce electricity by inducing current in the rotor without requiring synchronization with the grid frequency. Your choice between these two types depends on application needs such as grid stability and speed control.

Key Differences in Construction

Synchronous generators feature a rotor with a fixed magnetic field that rotates at a constant speed matching the grid frequency, while asynchronous generators (induction generators) have a rotor that rotates at a speed slightly different from the grid frequency. The construction of synchronous generators includes slip rings and brushes to supply the rotor winding with DC excitation, whereas asynchronous generators typically have a squirrel cage rotor with no external excitation needed. These construction distinctions result in different operational characteristics, such as synchronous speed operation for synchronous generators and variable speed operation for asynchronous generators.

Operating Speed and Frequency Characteristics

Synchronous generators operate at a fixed speed synchronized with the grid frequency, ensuring a constant frequency output crucial for stable power systems. Asynchronous generators, also known as induction generators, run at variable speeds slightly above synchronous speed, causing frequency to fluctuate based on load and speed variations. Understanding these differences helps you select the right generator type for applications requiring precise frequency control or variable-speed operation.

Voltage Regulation Capabilities

Synchronous generators provide superior voltage regulation capabilities due to their direct control over excitation, allowing for stable and adjustable output voltage under varying load conditions. Asynchronous generators, or induction generators, rely on the grid or external reactive power sources for voltage control, resulting in less precise voltage regulation and potential fluctuations during load changes. Understanding these differences helps you select the appropriate generator type for applications requiring consistent voltage stability.

Efficiency and Performance Comparison

Synchronous generators typically deliver higher efficiency and better voltage regulation compared to asynchronous generators, making them ideal for stable power supply applications. Asynchronous generators, while generally less efficient due to slip and reactive power consumption, offer robustness and simpler construction beneficial in variable-speed scenarios. Your choice between these generators should consider the specific efficiency requirements and operational conditions of your power system.

Applications and Industrial Use Cases

Synchronous generators are widely used in power plants and industrial facilities for grid-connected electricity generation due to their ability to maintain constant voltage and frequency, essential for stable power supply in large-scale applications. Asynchronous generators, commonly found in wind turbines and industrial motors, offer simpler construction and robustness, making them suitable for variable-speed applications and less critical synchronization conditions. Industries such as renewable energy and manufacturing utilize asynchronous generators for cost-effective and maintenance-friendly solutions, while synchronous generators dominate scenarios demanding precise control and high-quality power output.

Maintenance and Reliability Factors

Synchronous generators require regular maintenance of brushes, slip rings, and excitation systems to ensure stable voltage output and operational reliability. Asynchronous generators, often brushless and simpler in design, have lower maintenance demands but may experience variable voltage under load changes, affecting consistency. Reliability in synchronous generators is higher in critical applications due to precise control, while asynchronous types are favored for their robustness and lower upkeep in less sensitive environments.

Cost Implications and Economic Considerations

Synchronous generators typically involve higher initial costs due to complex construction and maintenance requirements, but they offer better voltage regulation and efficiency, leading to long-term savings. Asynchronous generators, also known as induction generators, have lower upfront expenses and simpler designs but may incur increased operational costs because of reduced efficiency and reactive power compensation needs. Your choice between these generators should balance immediate budget constraints with anticipated operational costs to optimize overall economic performance.

Choosing the Right Generator: A Comparative Summary

Selecting the right generator hinges on your specific application needs, with synchronous generators offering precise speed control and voltage regulation ideal for large-scale power plants or industrial use. Asynchronous generators, also known as induction generators, provide simpler construction, lower cost, and robustness, making them suitable for wind turbines and small-scale renewable energy systems. Understanding these key differences ensures your generator choice aligns with operational requirements and efficiency goals.

Synchronous generator vs Asynchronous generator Infographic

libmatt.com

libmatt.com