Oxy-fuel combustion uses pure oxygen instead of air, resulting in higher flame temperatures and more efficient fuel consumption compared to air-fuel combustion. Your process benefits from reduced nitrogen oxide emissions and increased thermal efficiency when using oxy-fuel technology.

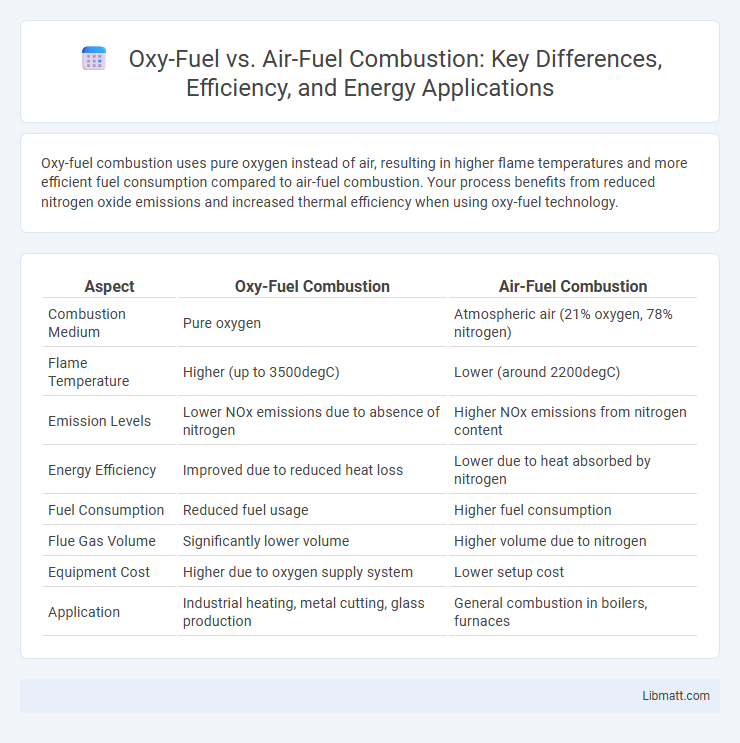

Table of Comparison

| Aspect | Oxy-Fuel Combustion | Air-Fuel Combustion |

|---|---|---|

| Combustion Medium | Pure oxygen | Atmospheric air (21% oxygen, 78% nitrogen) |

| Flame Temperature | Higher (up to 3500degC) | Lower (around 2200degC) |

| Emission Levels | Lower NOx emissions due to absence of nitrogen | Higher NOx emissions from nitrogen content |

| Energy Efficiency | Improved due to reduced heat loss | Lower due to heat absorbed by nitrogen |

| Fuel Consumption | Reduced fuel usage | Higher fuel consumption |

| Flue Gas Volume | Significantly lower volume | Higher volume due to nitrogen |

| Equipment Cost | Higher due to oxygen supply system | Lower setup cost |

| Application | Industrial heating, metal cutting, glass production | General combustion in boilers, furnaces |

Introduction to Combustion Technologies

Oxy-fuel combustion uses pure oxygen instead of air, resulting in higher flame temperatures and increased thermal efficiency compared to air-fuel combustion. This technology reduces nitrogen oxide emissions by minimizing nitrogen presence in the combustion process, enhancing environmental performance. Understanding these key differences helps you select the optimal combustion technology for improved energy output and lower emissions.

Understanding Oxy-Fuel Combustion

Oxy-fuel combustion utilizes pure oxygen instead of air, resulting in higher flame temperatures and increased thermal efficiency compared to air-fuel combustion, which mixes fuel with atmospheric air containing about 21% oxygen and 78% nitrogen. This process minimizes nitrogen dilution, reduces NOx emissions, and enhances heat transfer rates, making oxy-fuel combustion ideal for industrial applications requiring precise temperature control and lower pollutant output. The absence of nitrogen allows for easier CO2 capture and recycling, supporting more sustainable and environmentally friendly combustion systems.

Fundamentals of Air-Fuel Combustion

Air-fuel combustion relies on atmospheric air, which contains approximately 21% oxygen and 78% nitrogen, to support fuel oxidation and energy release in industrial processes. The presence of nitrogen dilutes the flame temperature, resulting in lower thermal efficiency and higher nitrogen oxide (NOx) emissions compared to oxy-fuel combustion. Understanding these fundamentals helps optimize combustion systems by adjusting air-to-fuel ratios for improved fuel efficiency and reduced pollutant output in your applications.

Key Differences Between Oxy-Fuel and Air-Fuel Methods

Oxy-fuel combustion uses pure oxygen instead of atmospheric air, resulting in higher flame temperatures and increased thermal efficiency compared to air-fuel combustion, which relies on nitrogen-rich air that dilutes combustion. The absence of nitrogen in oxy-fuel combustion reduces nitrogen oxide (NOx) emissions significantly, making it more environmentally friendly than air-fuel methods. Additionally, oxy-fuel systems enable easier carbon capture due to concentrated CO2 in exhaust gases, whereas air-fuel combustion produces a large volume of diluted flue gases.

Energy Efficiency Comparison

Oxy-fuel combustion significantly increases energy efficiency by using pure oxygen instead of air, which reduces nitrogen dilution and allows for higher flame temperatures and more complete fuel combustion. This results in improved thermal efficiency and reduced fuel consumption compared to traditional air-fuel combustion methods. Consequently, oxy-fuel systems offer enhanced energy savings and lower greenhouse gas emissions in industrial heating processes.

Environmental Impact Assessment

Oxy-fuel combustion significantly reduces nitrogen oxide (NOx) emissions compared to air-fuel combustion by eliminating nitrogen in the oxidizer, leading to lower air pollution and improved environmental quality. The concentrated CO2 stream produced during oxy-fuel combustion facilitates efficient carbon capture and storage (CCS), making it a more sustainable technology for reducing greenhouse gas emissions in industrial applications. In contrast, air-fuel combustion generates a larger volume of flue gases with diluted CO2, complicating emission control and increasing the environmental burden.

Industrial Applications of Each Combustion Type

Oxy-fuel combustion is extensively used in industries requiring high-temperature processes such as steel manufacturing, glass production, and waste incineration due to its ability to produce cleaner flames and reduce nitrogen oxide emissions. Air-fuel combustion remains prevalent in power generation, furnaces, and boilers where cost efficiency and simpler equipment design are prioritized despite higher nitrogen content in exhaust gases. The choice between oxy-fuel and air-fuel combustion often hinges on environmental regulations, fuel efficiency goals, and process-specific temperature requirements.

Cost Analysis: Oxy-Fuel vs Air-Fuel

Oxy-fuel combustion typically incurs higher initial costs due to oxygen production and equipment requirements but offers improved fuel efficiency and reduced waste, potentially lowering long-term operational expenses. Air-fuel combustion remains more cost-effective upfront but suffers from lower thermal efficiency and higher emissions, increasing maintenance and environmental compliance costs. Your choice depends on balancing immediate investment against potential savings through enhanced performance and sustainability.

Technological Challenges and Solutions

Oxy-fuel combustion faces technological challenges such as high flame temperatures leading to material degradation and the need for efficient oxygen separation to lower costs. Air-fuel combustion struggles with lower thermal efficiency and higher nitrogen oxide emissions due to the presence of atmospheric nitrogen. Your choice of combustion technology can benefit from advanced ceramics and membrane oxygen separation to address these issues and improve performance.

Future Trends in Combustion Technology

Oxy-fuel combustion offers higher flame temperatures and lower nitrogen oxide emissions compared to air-fuel combustion, making it a key focus in advancing cleaner industrial processes. Future trends emphasize integrating oxy-fuel technology with carbon capture and storage (CCS) to reduce greenhouse gas emissions significantly. You can expect ongoing innovation in burner designs and combustion control systems to enhance efficiency and sustainability in energy production.

Oxy-Fuel vs Air-Fuel Combustion Infographic

libmatt.com

libmatt.com