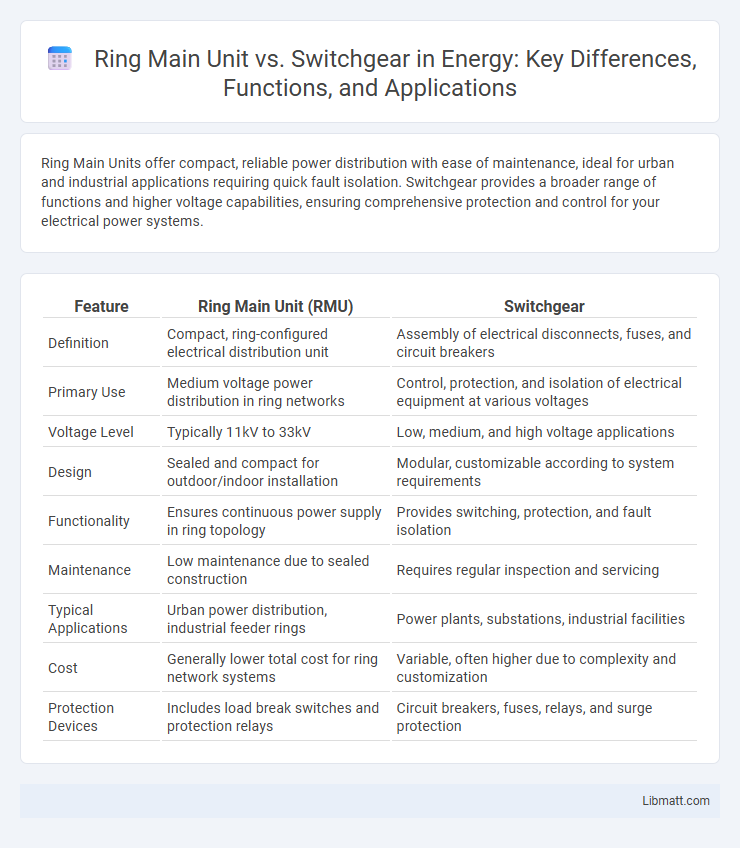

Ring Main Units offer compact, reliable power distribution with ease of maintenance, ideal for urban and industrial applications requiring quick fault isolation. Switchgear provides a broader range of functions and higher voltage capabilities, ensuring comprehensive protection and control for your electrical power systems.

Table of Comparison

| Feature | Ring Main Unit (RMU) | Switchgear |

|---|---|---|

| Definition | Compact, ring-configured electrical distribution unit | Assembly of electrical disconnects, fuses, and circuit breakers |

| Primary Use | Medium voltage power distribution in ring networks | Control, protection, and isolation of electrical equipment at various voltages |

| Voltage Level | Typically 11kV to 33kV | Low, medium, and high voltage applications |

| Design | Sealed and compact for outdoor/indoor installation | Modular, customizable according to system requirements |

| Functionality | Ensures continuous power supply in ring topology | Provides switching, protection, and fault isolation |

| Maintenance | Low maintenance due to sealed construction | Requires regular inspection and servicing |

| Typical Applications | Urban power distribution, industrial feeder rings | Power plants, substations, industrial facilities |

| Cost | Generally lower total cost for ring network systems | Variable, often higher due to complexity and customization |

| Protection Devices | Includes load break switches and protection relays | Circuit breakers, fuses, relays, and surge protection |

Overview of Ring Main Unit and Switchgear

Ring Main Unit (RMU) is a compact, metal-enclosed electric distribution device designed for medium-voltage power networks, ensuring reliable switching and protection in ring or radial configurations. Switchgear broadly encompasses electrical equipment such as circuit breakers, disconnectors, and fuses used for controlling, protecting, and isolating electrical circuits in both medium and high-voltage applications. RMUs are specialized switchgear units optimized for ring distribution systems, offering enhanced safety, operational efficiency, and fault isolation in urban utility and industrial power grids.

Key Differences Between RMU and Switchgear

Ring Main Units (RMUs) are compact, gas-insulated switchgear primarily used for medium-voltage network distribution, offering reliable ring network configurations and easy maintenance. Switchgear is a broader category encompassing devices used to control, protect, and isolate electrical equipment, available in various types such as circuit breakers, fuses, and disconnect switches, covering low, medium, and high voltage applications. Your choice between RMU and switchgear depends on the specific electrical distribution needs, space constraints, and voltage level requirements.

Construction and Design Aspects

Ring Main Units (RMUs) feature a compact, sealed, metal-enclosed design with integrated load break switches and vacuum interrupters, ensuring high reliability and minimal maintenance in medium-voltage networks. Switchgear encompasses a broader category, often including circuit breakers, fuses, and isolators with more modular and customizable construction suited for diverse voltage levels and application demands. RMUs are typically designed for easy installation in confined spaces, while switchgear units prioritize scalability and comprehensive protection capabilities in substations.

Functions and Applications

Ring Main Units (RMUs) are specialized switchgear designed for medium voltage distribution networks, providing reliable switching, protection, and isolation of electrical circuits. Switchgear encompasses a broader category of devices for controlling, protecting, and isolating electrical equipment across a wide range of voltages, including RMUs as a subset for ring-type power distribution. RMUs are commonly applied in urban power distribution systems for load continuity and fault isolation, while general switchgear is used in diverse industrial, commercial, and utility settings for comprehensive electrical system management.

Safety Features Comparison

Ring Main Units (RMUs) offer enhanced safety features such as enclosed, gas-insulated circuit breakers that prevent arc flash hazards and reduce maintenance risks compared to traditional air-insulated switchgear. RMUs are designed with compact, modular components that provide secure fault isolation and minimize the risk of accidental contact during operation. Switchgear safety primarily depends on design type and insulation medium, but RMUs typically deliver superior protection through advanced interlocking mechanisms and robust fault detection systems.

Installation and Maintenance Requirements

Ring Main Units (RMUs) offer compact and modular installation that simplifies setup in confined spaces, often reducing the need for extensive civil works compared to traditional switchgear. Maintenance of RMUs is typically less frequent and easier due to their sealed design and integrated components, while switchgear usually requires more routine inspections and component replacements to ensure reliability. Your choice between RMUs and switchgear should consider the ease-of-installation and long-term upkeep to optimize operational efficiency and reduce downtime.

Cost Considerations and Economical Impacts

Ring Main Units (RMUs) generally offer lower initial installation costs compared to traditional switchgear due to their compact design and ease of integration in distribution networks. The reduced maintenance expenses and higher reliability of RMUs contribute to long-term economic benefits by minimizing downtime and operational disruptions. Conversely, traditional switchgear may involve higher upfront investment but can offer greater flexibility for complex power systems, impacting overall cost-effectiveness depending on application requirements.

Performance and Reliability Factors

Ring Main Units (RMUs) offer enhanced reliability through their ring configuration that allows continuous power supply even if one section fails, making them ideal for urban distribution networks. Switchgear performance depends heavily on the type of circuit breaker used and the quality of insulation, impacting operational longevity and fault interruption capabilities. RMUs typically have fewer moving parts and are compact, resulting in lower maintenance requirements and higher operational uptime compared to traditional switchgear setups.

Suitability for Various Power Distribution Networks

Ring Main Units (RMUs) are highly suitable for medium-voltage power distribution networks requiring compact, modular solutions with reliable fault isolation and minimal downtime, commonly used in urban and industrial settings. Switchgear encompasses a broader range of devices, ideal for both low-voltage and high-voltage power distribution systems, providing comprehensive protection, control, and isolation across transmission substations and distribution networks. RMUs excel in ring configurations for network redundancy, while switchgear offers versatile capabilities for diverse network topologies and load demands.

Conclusion: Choosing Between RMU and Switchgear

Selecting between a Ring Main Unit (RMU) and switchgear depends on the application requirements, system complexity, and safety standards. RMUs offer compact, cost-effective solutions for medium-voltage distribution in urban or constrained spaces, while switchgear provides higher flexibility and enhanced protection for diverse voltage levels and larger power systems. Evaluating factors such as maintenance needs, operational reliability, and installation environments ensures the optimal choice for electrical distribution and fault management.

Ring Main Unit vs Switchgear Infographic

libmatt.com

libmatt.com