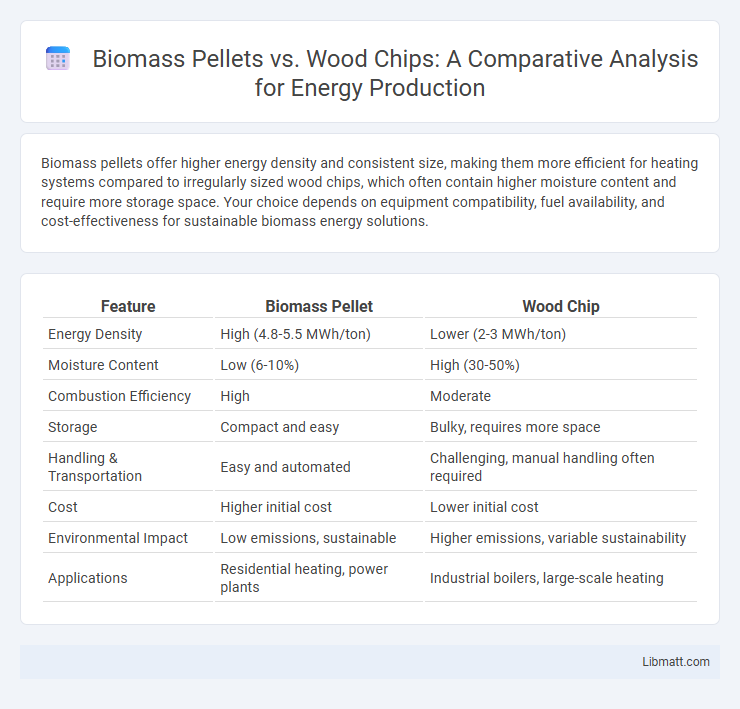

Biomass pellets offer higher energy density and consistent size, making them more efficient for heating systems compared to irregularly sized wood chips, which often contain higher moisture content and require more storage space. Your choice depends on equipment compatibility, fuel availability, and cost-effectiveness for sustainable biomass energy solutions.

Table of Comparison

| Feature | Biomass Pellet | Wood Chip |

|---|---|---|

| Energy Density | High (4.8-5.5 MWh/ton) | Lower (2-3 MWh/ton) |

| Moisture Content | Low (6-10%) | High (30-50%) |

| Combustion Efficiency | High | Moderate |

| Storage | Compact and easy | Bulky, requires more space |

| Handling & Transportation | Easy and automated | Challenging, manual handling often required |

| Cost | Higher initial cost | Lower initial cost |

| Environmental Impact | Low emissions, sustainable | Higher emissions, variable sustainability |

| Applications | Residential heating, power plants | Industrial boilers, large-scale heating |

Introduction to Biomass Pellet and Wood Chip

Biomass pellets are compact, cylindrical fuel made from compressed organic materials such as sawdust, agricultural residue, and wood shavings, offering high energy density and consistent combustion. Wood chips are larger, irregularly shaped pieces derived directly from wood processing or forestry residues, providing a cost-effective but less energy-dense biomass fuel option. Both biomass pellets and wood chips serve as renewable energy sources, widely used in heating systems and power generation with varying efficiencies and handling requirements.

Composition and Raw Materials

Biomass pellets are typically composed of compacted sawdust, agricultural residues, and compressed biomass materials with low moisture content, ensuring high energy density and consistent combustion properties. Wood chips consist of larger, irregularly sized pieces derived directly from wood logs, branches, or wood processing residues, often containing higher moisture and variable bark content. The choice of raw materials affects the fuel's calorific value, ash content, and suitability for specific combustion systems.

Production Process Comparison

Biomass pellet production involves drying, grinding, and compressing raw materials into dense, uniform pellets, enhancing energy density and ease of transport. Wood chip production primarily includes chipping logs or wood waste into irregular, coarse particles requiring less processing but offering lower energy density. Understanding these differences helps you choose the appropriate biomass fuel based on efficiency and handling requirements.

Energy Content and Efficiency

Biomass pellets typically have a higher energy content, averaging around 16-18 MJ/kg, compared to wood chips, which range from 10-15 MJ/kg due to their higher moisture content and lower density. Pellets offer greater combustion efficiency, often exceeding 85%, as their uniform size and low moisture enable more complete and consistent burning. Wood chips, while cost-effective and easier to produce, generally have lower thermal efficiency, typically between 50-70%, making pellets the preferred choice for maximizing energy output in residential and industrial heating systems.

Storage and Handling Requirements

Biomass pellets require dry, secure storage to prevent moisture absorption, which can compromise fuel quality and combustion efficiency. Wood chips demand larger, well-ventilated storage areas to avoid mold growth and spontaneous combustion due to their higher moisture content and bulk density. Proper handling equipment is essential for both, but pellets allow for easier automated feeding systems, enhancing your operational convenience.

Environmental Impact and Sustainability

Biomass pellets have a higher energy density and lower moisture content compared to wood chips, resulting in more efficient combustion with reduced greenhouse gas emissions, enhancing their environmental sustainability. Wood chips, often sourced from forestry residues and waste, promote resource circularity but can have higher transportation and storage emissions due to bulkiness and moisture variability. Both biomass pellets and wood chips contribute significantly to renewable energy targets by utilizing carbon-neutral feedstocks, yet pellets generally demonstrate superior lifecycle emissions performance and consistent quality for sustainable bioenergy production.

Cost Analysis: Biomass Pellet vs Wood Chip

Biomass pellets generally incur higher initial production and processing costs compared to wood chips due to their uniform size, density, and lower moisture content, which improve combustion efficiency. Wood chips offer a cost advantage in raw material acquisition and minimal processing, but their lower energy density and higher moisture content can lead to increased transportation and storage expenses. Analyzing total cost of ownership reveals that while pellets have higher upfront costs, their superior energy output and operational efficiency can result in lower fuel consumption and long-term savings compared to wood chips.

Applications in Heating and Power Generation

Biomass pellets offer higher energy density and consistent size, making them ideal for automated heating systems and large-scale power generation plants. Wood chips, while less energy-dense, suit industrial boilers and smaller heating applications where bulk handling is preferred. Your choice between biomass pellets and wood chips depends on the efficiency requirements and the scale of your heating or power generation system.

Transportation and Logistics

Biomass pellets offer higher energy density and uniform size, enabling more efficient stacking and transport compared to irregularly shaped wood chips, which occupy more volume and require specialized handling. Pellets' low moisture content reduces weight and risk of degradation during long-distance logistics, whereas wood chips' higher moisture levels increase transportation costs and potential for microbial growth. Efficient pelletized biomass transport streamlines supply chains and reduces freight expenses, making pellets preferable for centralized energy production facilities.

Choosing the Right Option for Your Needs

Biomass pellets offer high energy density and consistent combustion, making them ideal for efficient heating systems and compact storage needs. Wood chips are typically more cost-effective and suitable for larger-scale applications like industrial boilers or outdoor biomass plants due to their lower processing requirements. Evaluating factors such as budget, energy output, storage space, and equipment compatibility is essential when deciding between biomass pellets and wood chips.

Biomass Pellet vs Wood Chip Infographic

libmatt.com

libmatt.com