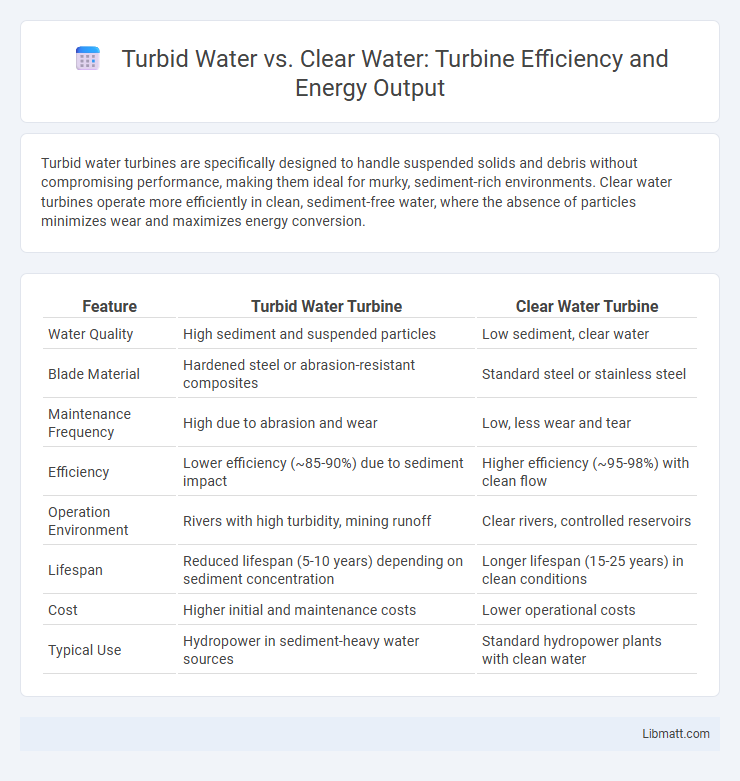

Turbid water turbines are specifically designed to handle suspended solids and debris without compromising performance, making them ideal for murky, sediment-rich environments. Clear water turbines operate more efficiently in clean, sediment-free water, where the absence of particles minimizes wear and maximizes energy conversion.

Table of Comparison

| Feature | Turbid Water Turbine | Clear Water Turbine |

|---|---|---|

| Water Quality | High sediment and suspended particles | Low sediment, clear water |

| Blade Material | Hardened steel or abrasion-resistant composites | Standard steel or stainless steel |

| Maintenance Frequency | High due to abrasion and wear | Low, less wear and tear |

| Efficiency | Lower efficiency (~85-90%) due to sediment impact | Higher efficiency (~95-98%) with clean flow |

| Operation Environment | Rivers with high turbidity, mining runoff | Clear rivers, controlled reservoirs |

| Lifespan | Reduced lifespan (5-10 years) depending on sediment concentration | Longer lifespan (15-25 years) in clean conditions |

| Cost | Higher initial and maintenance costs | Lower operational costs |

| Typical Use | Hydropower in sediment-heavy water sources | Standard hydropower plants with clean water |

Introduction to Turbid and Clear Water Turbines

Turbid water turbines are specifically engineered to handle water containing high levels of suspended sediments, preventing abrasion and erosion of turbine components. Clear water turbines operate efficiently in sediment-free or low-turbidity conditions, allowing for optimized performance and reduced maintenance. Understanding the differences in design and operational requirements is crucial for selecting the appropriate turbine for varying water quality environments.

Understanding Water Turbidity: Key Definitions

Water turbidity refers to the cloudiness or haziness of a fluid caused by suspended solids such as silt, clay, algae, and organic matter that scatter light. Clear water turbines are designed to operate efficiently in low-turbidity conditions, where water contains minimal suspended particles, ensuring optimal energy conversion. Understanding your local water turbidity levels is crucial for selecting the appropriate turbine type, as high-turbidity water can cause increased wear and reduced performance in traditional clear water turbine systems.

Types of Turbines for Various Water Conditions

Pelton, Francis, and Kaplan turbines are commonly selected based on water clarity and sediment load; Pelton turbines excel in clear, high-head, low-flow conditions, while Francis turbines accommodate moderate sediment loads with medium heads. Kaplan turbines are ideal for turbid, low-head, high-flow environments due to their adjustable blades that handle varying water conditions and sediment concentrations efficiently. Understanding the turbidity level and hydraulic characteristics of the water source ensures optimal turbine performance, durability, and energy output in hydroelectric power generation.

Efficiency Comparison: Turbid vs Clear Water Turbines

Turbid water turbines experience reduced efficiency compared to clear water turbines due to sediment and particulate buildup that increases wear and energy loss. Clear water turbines maintain optimal performance by minimizing abrasion and preserving hydrodynamic flow, resulting in higher energy conversion rates. For your energy projects, selecting a turbine suited to water conditions ensures longevity and maximized efficiency.

Impact of Suspended Solids on Turbine Performance

Suspended solids in turbid water significantly reduce turbine performance by causing abrasion and clogging of turbine blades, leading to increased wear and maintenance costs. Clear water turbines operate more efficiently as they face less mechanical resistance and lower risk of damage, maximizing energy output. Your choice of turbine must consider sediment load to ensure optimal efficiency and longevity in varying water conditions.

Maintenance Challenges in Turbid Water Environments

Turbid water turbines face significant maintenance challenges due to abrasive particles, such as sand and silt, which accelerate wear on blades, bearings, and seals, reducing operational lifespan. Sediment accumulation leads to frequent cleaning requirements and increased risk of clogging, impacting turbine efficiency and causing unexpected downtime. Corrosion rates are also higher in turbid water, necessitating robust material selection and ongoing inspection protocols to ensure reliable performance.

Material Selection for Optimal Turbine Operation

Material selection for turbines operating in turbid water prioritizes corrosion resistance and abrasion durability to withstand suspended solids and sediment erosion. High-grade stainless steel and specialized composite materials are commonly used to ensure longevity and maintain efficiency under harsh conditions. In contrast, turbines in clear water environments can utilize less abrasion-resistant materials, allowing for cost-effective manufacturing while still maintaining optimal performance.

Environmental Impacts of Turbine Choice

Turbines designed for turbid water often require robust materials and maintenance to handle sediment abrasion, reducing operational lifespan and increasing environmental footprint due to frequent replacements. Clear water turbines typically induce less ecological disturbance by minimizing sediment disruption and preserving aquatic habitats, contributing to sustained biodiversity. Selecting turbines compatible with water clarity is critical for reducing sediment-related turbidity downstream and preventing habitat degradation.

Case Studies: Real-World Applications

Case studies reveal that turbid water turbines, such as those deployed in the Amazon River basin, excel in environments with high sediment loads, maintaining efficiency despite suspended solids that would damage clear water turbines. In contrast, clear water turbines used in the Swiss Rhine hydroelectric plants demonstrate superior performance in sediment-free conditions, harnessing energy more efficiently with minimal maintenance. These real-world applications highlight the importance of matching turbine types to water clarity and sediment content to optimize operational lifespan and energy output.

Future Trends in Turbine Technology for Different Water Qualities

Future trends in turbine technology emphasize enhancing efficiency and durability for diverse water qualities, including turbid and clear water environments. Innovations in materials like corrosion-resistant composites and advanced coatings are designed to withstand abrasive sediments found in turbid water, reducing wear and extending turbine lifespan. Integration of smart sensors and AI-driven monitoring systems optimizes real-time performance, enabling adaptive operation based on water clarity and flow conditions for improved energy output and maintenance scheduling.

Turbid Water vs Clear Water Turbine Infographic

libmatt.com

libmatt.com