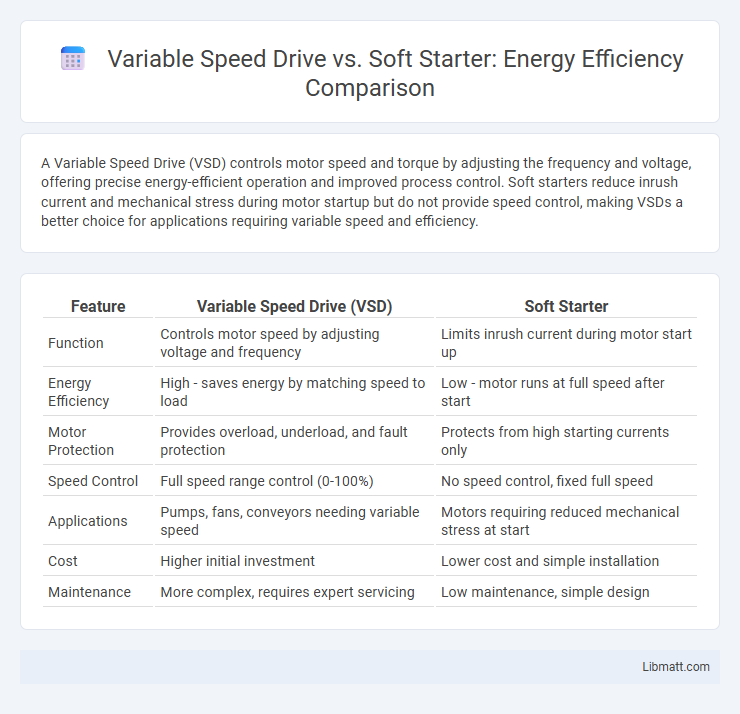

A Variable Speed Drive (VSD) controls motor speed and torque by adjusting the frequency and voltage, offering precise energy-efficient operation and improved process control. Soft starters reduce inrush current and mechanical stress during motor startup but do not provide speed control, making VSDs a better choice for applications requiring variable speed and efficiency.

Table of Comparison

| Feature | Variable Speed Drive (VSD) | Soft Starter |

|---|---|---|

| Function | Controls motor speed by adjusting voltage and frequency | Limits inrush current during motor start up |

| Energy Efficiency | High - saves energy by matching speed to load | Low - motor runs at full speed after start |

| Motor Protection | Provides overload, underload, and fault protection | Protects from high starting currents only |

| Speed Control | Full speed range control (0-100%) | No speed control, fixed full speed |

| Applications | Pumps, fans, conveyors needing variable speed | Motors requiring reduced mechanical stress at start |

| Cost | Higher initial investment | Lower cost and simple installation |

| Maintenance | More complex, requires expert servicing | Low maintenance, simple design |

Introduction to Variable Speed Drives and Soft Starters

Variable Speed Drives (VSDs) control motor speed and torque by varying input frequency and voltage, enhancing energy efficiency and process precision in industrial applications. Soft starters limit the inrush current during motor startup by gradually increasing voltage, reducing mechanical stress and electrical peaks without altering motor speed. Understanding these differences is critical for optimizing motor performance, energy consumption, and equipment lifespan in automation systems.

How Variable Speed Drives Work

Variable Speed Drives (VSDs) regulate motor speed by adjusting the frequency and voltage supplied to the electric motor, enabling precise control over acceleration and deceleration. By converting incoming AC power to DC and then using an inverter to produce variable frequency AC power, VSDs optimize energy consumption and improve process efficiency. This precise motor speed control reduces mechanical stress, increases equipment lifespan, and provides enhanced operational flexibility compared to soft starters.

How Soft Starters Operate

Soft starters operate by gradually ramping up voltage to the motor during startup, reducing inrush current and mechanical stress on electrical components. This controlled voltage increase limits the initial torque, preventing sudden shocks to the system and extending the motor's lifespan. Unlike variable speed drives, soft starters do not provide precise speed control but offer efficient motor protection during the startup phase.

Key Differences Between VSDs and Soft Starters

Variable Speed Drives (VSDs) offer precise control of motor speed and torque by adjusting the frequency and voltage supplied to the motor, leading to enhanced energy efficiency and process optimization. Soft starters primarily reduce inrush current during motor startup by gradually ramping up voltage, minimizing mechanical stress but do not control motor speed once running. VSDs enable continuous speed variation for dynamic load control, whereas soft starters are limited to smooth starting and stopping without speed modulation capabilities.

Energy Efficiency Comparison

Variable Speed Drives (VSDs) offer superior energy efficiency by precisely controlling motor speed to match load requirements, reducing power consumption significantly compared to Soft Starters, which primarily limit inrush current without adjusting operational speed. Soft Starters are less efficient during continuous operation since they run the motor at full speed, leading to higher energy usage. Your energy savings are maximized with VSDs, especially in applications with variable load demands, making them the preferred choice for optimizing electrical consumption.

Applications Best Suited for Variable Speed Drives

Variable Speed Drives (VSDs) are best suited for applications requiring precise control of motor speed and torque, such as conveyor systems, pumps, fans, and HVAC systems. You benefit from their energy efficiency and enhanced process control in industries like manufacturing, HVAC, and water treatment. Unlike soft starters, VSDs optimize performance by continuously adjusting motor speed to match load requirements, reducing wear and operational costs.

Applications Best Suited for Soft Starters

Soft starters are ideal for applications requiring reduced inrush current and smooth motor startup without altering the motor's operating speed, such as pumps, fans, and compressors. They excel in extending equipment life by minimizing mechanical stress and electrical surge during startup. Your choice of soft starter suits environments where simple acceleration control is sufficient, avoiding the complexity of variable speed adjustments.

Cost Analysis: VSD vs Soft Starter

Variable Speed Drives (VSDs) typically have a higher initial cost compared to Soft Starters due to advanced electronics and control features. However, VSDs offer significant energy savings by optimizing motor speed, which can reduce operating costs over time, making them cost-effective for applications with variable load requirements. Your choice should consider both upfront investment and long-term energy efficiency benefits to achieve the best return on investment.

Maintenance and Reliability Considerations

Variable Speed Drives (VSDs) require regular maintenance of cooling systems and control components to ensure reliability, while Soft Starters have fewer moving parts, resulting in lower overall maintenance demands. VSDs offer precise speed control, which reduces mechanical stress on equipment and can extend motor life, enhancing system reliability. Your choice should consider the balance between maintenance capabilities and the operational benefits each technology provides for your specific application.

Choosing the Right Solution for Your Motor System

Variable Speed Drives (VSDs) provide precise motor speed control and energy efficiency for applications requiring variable torque and speed adjustments. Soft Starters offer a cost-effective solution for reducing inrush current and mechanical stress during motor startup but lack continuous speed control. Choosing the right solution depends on your motor system's operational needs, with VSDs ideal for dynamic control and Soft Starters suited for simple soft starting applications.

Variable Speed Drive vs Soft Starter Infographic

libmatt.com

libmatt.com