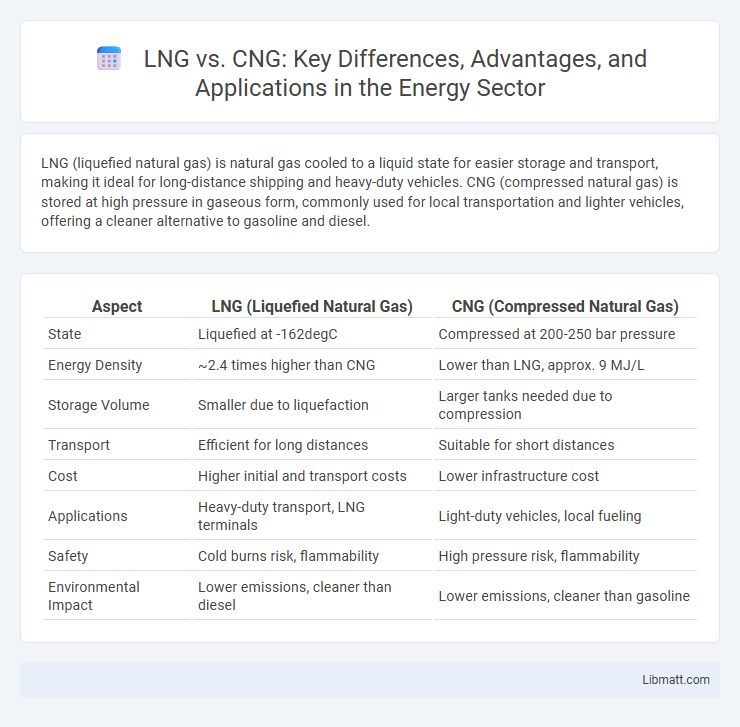

LNG (liquefied natural gas) is natural gas cooled to a liquid state for easier storage and transport, making it ideal for long-distance shipping and heavy-duty vehicles. CNG (compressed natural gas) is stored at high pressure in gaseous form, commonly used for local transportation and lighter vehicles, offering a cleaner alternative to gasoline and diesel.

Table of Comparison

| Aspect | LNG (Liquefied Natural Gas) | CNG (Compressed Natural Gas) |

|---|---|---|

| State | Liquefied at -162degC | Compressed at 200-250 bar pressure |

| Energy Density | ~2.4 times higher than CNG | Lower than LNG, approx. 9 MJ/L |

| Storage Volume | Smaller due to liquefaction | Larger tanks needed due to compression |

| Transport | Efficient for long distances | Suitable for short distances |

| Cost | Higher initial and transport costs | Lower infrastructure cost |

| Applications | Heavy-duty transport, LNG terminals | Light-duty vehicles, local fueling |

| Safety | Cold burns risk, flammability | High pressure risk, flammability |

| Environmental Impact | Lower emissions, cleaner than diesel | Lower emissions, cleaner than gasoline |

Introduction to LNG and CNG

Liquefied Natural Gas (LNG) is natural gas cooled to approximately -162degC, transforming it into a liquid state to reduce volume for efficient storage and transportation. Compressed Natural Gas (CNG) is natural gas stored at high pressure, typically around 200-250 bar, in gaseous form used primarily for vehicle fuel. LNG offers higher energy density compared to CNG, making it suitable for long-distance and heavy-duty applications.

Key Differences Between LNG and CNG

LNG (liquefied natural gas) is natural gas cooled to -162degC, resulting in a liquid state that occupies about 1/600th of its gas volume, while CNG (compressed natural gas) is natural gas compressed to high pressure, typically 200-250 bar, but remains in gaseous form. LNG offers higher energy density and is more suitable for long-distance transportation and heavy-duty vehicles, whereas CNG is commonly used for short-range applications and light-duty vehicles due to its easier storage and refueling. Understanding these key differences helps you choose the most efficient and cost-effective option for your energy needs or fleet requirements.

Production and Storage Methods

Liquefied Natural Gas (LNG) is produced by cooling natural gas to -162degC (-260degF), transforming it into a liquid state, which reduces its volume by approximately 600 times for efficient storage and transportation. Compressed Natural Gas (CNG) is produced by compressing natural gas to pressures around 200-250 bar, storing it as a gas in high-pressure cylinders. LNG requires cryogenic tanks with advanced insulation for storage, while CNG is stored in robust, high-pressure vessels designed to withstand extreme pressures safely.

Energy Density and Efficiency Comparison

LNG (liquefied natural gas) has a significantly higher energy density compared to CNG (compressed natural gas), offering about 2.4 times more energy per unit volume, making it ideal for long-haul transportation and storage. The liquefaction process of LNG allows it to be stored at very low temperatures, enhancing energy efficiency during transport, while CNG requires high-pressure compression, which can lead to greater energy loss. Understanding the differences in energy density and efficiency helps optimize your fuel choice for specific applications, balancing cost and performance needs effectively.

Infrastructure Requirements

LNG infrastructure requires specialized cryogenic storage tanks and insulated pipelines to maintain natural gas in its liquefied state at around -162degC, making it more capital-intensive compared to CNG. CNG relies on high-pressure compressors and reinforced storage cylinders capable of withstanding pressures up to 250 bar, benefiting from existing natural gas pipeline networks for distribution. The complexity and cost of LNG infrastructure limit its deployment primarily to large-scale fueling stations and shipping terminals, whereas CNG infrastructure is more widespread for vehicular and local distribution applications.

Environmental Impact

LNG (liquefied natural gas) has a lower carbon footprint compared to traditional fossil fuels due to its cleaner combustion process, producing fewer greenhouse gas emissions and pollutants. CNG (compressed natural gas) also offers environmental benefits by significantly reducing carbon monoxide, nitrogen oxides, and particulate matter emissions relative to diesel or gasoline. Your choice between LNG and CNG impacts the level of greenhouse gas reductions and air quality improvements achievable in transportation or industrial applications.

Cost Analysis: LNG vs CNG

LNG typically incurs higher upfront infrastructure costs due to complex liquefaction and storage requirements, while CNG systems benefit from lower initial investment using high-pressure compression units. Operating costs for LNG can be more economical over long distances and heavy-duty applications because of its higher energy density, which reduces fuel consumption and refueling frequency. Your choice should consider total lifecycle costs, including equipment, fuel prices, and maintenance, to determine the most cost-effective solution for specific transportation or industrial needs.

Safety Considerations

LNG (Liquefied Natural Gas) and CNG (Compressed Natural Gas) differ significantly in safety considerations due to their states and storage methods. LNG is stored at extremely low temperatures (-162degC), requiring insulated tanks to prevent rapid vaporization and potential cold burns, while CNG is stored at high pressures (up to 3,600 psi), necessitating robust pressure vessels to avoid rupture risks. Understanding these safety factors helps you make informed decisions regarding fuel handling, storage, and transportation protocols to minimize hazards effectively.

Applications in Transportation and Industry

LNG (Liquefied Natural Gas) is widely used in heavy-duty transportation such as long-haul trucks, ships, and trains due to its higher energy density and lower volume compared to CNG (Compressed Natural Gas), making it more suitable for long-distance and high-capacity fuel needs. CNG is commonly utilized in light-duty vehicles, buses, and fleet vehicles within urban environments where refueling infrastructure is readily available and lower storage pressure enhances safety and cost-effectiveness. In industry, LNG powers large-scale operations requiring continuous high-energy input, while CNG supports smaller-scale industrial machinery and onsite power generation where pipeline connectivity or direct gas compression is accessible.

Future Prospects and Market Trends

The future prospects for LNG (liquefied natural gas) indicate robust growth driven by increasing demand in heavy transportation, maritime shipping, and power generation due to its higher energy density and lower carbon emissions compared to CNG (compressed natural gas). Market trends show LNG infrastructure expansion worldwide, including new liquefaction plants and regasification terminals, while CNG remains popular for light-duty vehicles and urban transit fleets because of its cost-effectiveness and easier refueling. Your choice between LNG and CNG should consider these evolving market dynamics, particularly as regulations push for cleaner fuels and technological advancements enhance the efficiency of both forms.

LNG vs CNG Infographic

libmatt.com

libmatt.com