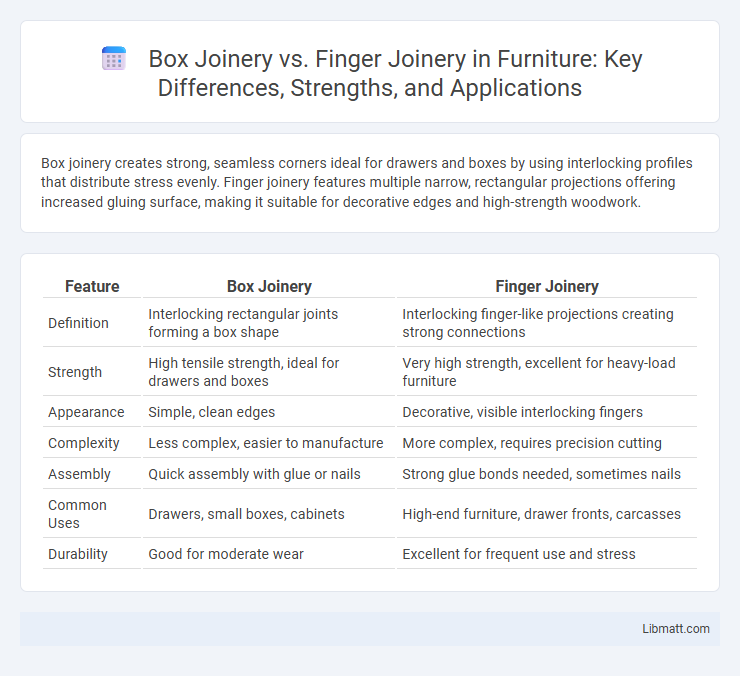

Box joinery creates strong, seamless corners ideal for drawers and boxes by using interlocking profiles that distribute stress evenly. Finger joinery features multiple narrow, rectangular projections offering increased gluing surface, making it suitable for decorative edges and high-strength woodwork.

Table of Comparison

| Feature | Box Joinery | Finger Joinery |

|---|---|---|

| Definition | Interlocking rectangular joints forming a box shape | Interlocking finger-like projections creating strong connections |

| Strength | High tensile strength, ideal for drawers and boxes | Very high strength, excellent for heavy-load furniture |

| Appearance | Simple, clean edges | Decorative, visible interlocking fingers |

| Complexity | Less complex, easier to manufacture | More complex, requires precision cutting |

| Assembly | Quick assembly with glue or nails | Strong glue bonds needed, sometimes nails |

| Common Uses | Drawers, small boxes, cabinets | High-end furniture, drawer fronts, carcasses |

| Durability | Good for moderate wear | Excellent for frequent use and stress |

Introduction to Box Joinery and Finger Joinery

Box joinery involves interlocking rectangular or square fingers cut into two pieces of wood, creating a strong and precise corner joint commonly used in drawer construction and cabinetry. Finger joinery, also known as comb joinery, features multiple thin, evenly spaced projections that interlock, maximizing glue surface area for enhanced strength in box or frame assemblies. Both techniques rely on careful machining and adhesive application to create durable joints suited for woodworking projects requiring high structural integrity.

Understanding Box Joinery

Box joinery is a woodworking technique characterized by interlocking square or rectangular finger-like projections that fit together to form strong, durable corners. This method is widely used in drawer construction and cabinetry due to its excellent resistance to pulling forces, ensuring your furniture maintains structural integrity over time. Understanding box joinery allows you to achieve precise, clean corners with enhanced mechanical strength compared to simpler butt joints.

What Is Finger Joinery?

Finger joinery is a woodworking technique that involves interlocking rectangular "fingers" cut into the ends of two pieces of wood to create a strong, durable joint. This method increases the surface area for gluing, enhancing the joint's mechanical strength and stability compared to simple butt joints. Finger joints are commonly used in box construction, furniture making, and other applications requiring precise alignment and robust corner connections.

Key Differences Between Box and Finger Joinery

Box joinery features interlocking square pins and sockets creating strong, box-shaped corners ideal for drawer construction, while finger joinery uses longer, narrower fingers that provide increased glue surface and enhanced tensile strength. Finger joints are typically more precise and visually uniform, making them suitable for decorative woodworking projects, whereas box joints offer robust mechanical strength and simpler assembly. Both techniques improve joint durability through increased gluing area, but differ significantly in appearance, application, and structural characteristics.

Strength and Durability Comparison

Box joinery provides superior strength and durability due to its full-thickness interlocking corners, which distribute stress evenly and resist twisting. Finger joinery, with its multiple narrow fingers glued together, offers strong tensile strength but may be prone to weakness under heavy loads or shear forces. Your choice should consider the specific stress conditions, as box joints excel in load-bearing applications while finger joints are ideal for precise alignment and aesthetics.

Applications for Box and Finger Joints

Box joinery excels in constructing drawers, decorative boxes, and small furniture components due to its strong interlocking design that resists pulling apart. Finger joinery is widely applied in cabinet making, door panels, and larger frame constructions, offering extended surface area for gluing and enhanced strength in tensile load applications. Both joinery techniques provide durable, precise connections suited for varying woodworking projects requiring robust corner joints.

Tools and Materials Needed

Box joinery requires basic tools such as a table saw or router with a box joint jig, along with wood glue and clamps for assembly, making it suitable for straightforward woodworking projects using hardwood or plywood. Finger joinery demands precise tools like a router with a finger joint bit or specialized finger joint cutters, combined with strong adhesives and well-prepared softwood or hardwood materials to ensure a durable interlocking fit. Choosing the right tools and materials directly impacts the strength and finish quality of your joinery project.

Aesthetic Considerations

Box joinery offers clean, minimalist lines ideal for modern or contemporary furniture designs, while finger joinery creates a visually striking pattern with interlocking fingers that highlight craftsmanship and detail. Your choice impacts the overall aesthetics, as box joints emphasize simplicity and strength, whereas finger joints add decorative appeal and intricate texture. Selecting between the two depends on whether you prioritize subtle elegance or ornamental complexity in your woodworking projects.

Pros and Cons of Each Joinery Method

Box joinery offers strong corner stability and clean appearance, making it ideal for drawers and boxes, but it requires precise cuts and can be time-consuming. Finger joinery provides increased glue surface area for enhanced strength and is easier to automate with CNC machines, yet it may show visible joints and requires careful alignment to avoid gaps. Both methods improve joint durability compared to basic butt joints, with selection depending on project aesthetics and manufacturing capabilities.

Which Joinery Method Should You Choose?

Box joinery offers superior strength and durability, making it ideal for heavy-duty woodworking projects like drawers and chests, while finger joinery excels in creating precise, interlocking joints suited for decorative or smaller-scale furniture. Your choice should depend on the specific requirements of your project, such as load-bearing capacity and aesthetic preference. Considering the ease of assembly, box joinery generally provides a more robust and long-lasting connection, whereas finger joinery allows for intricate patterns and enhanced visual appeal.

Box Joinery vs Finger Joinery Infographic

libmatt.com

libmatt.com