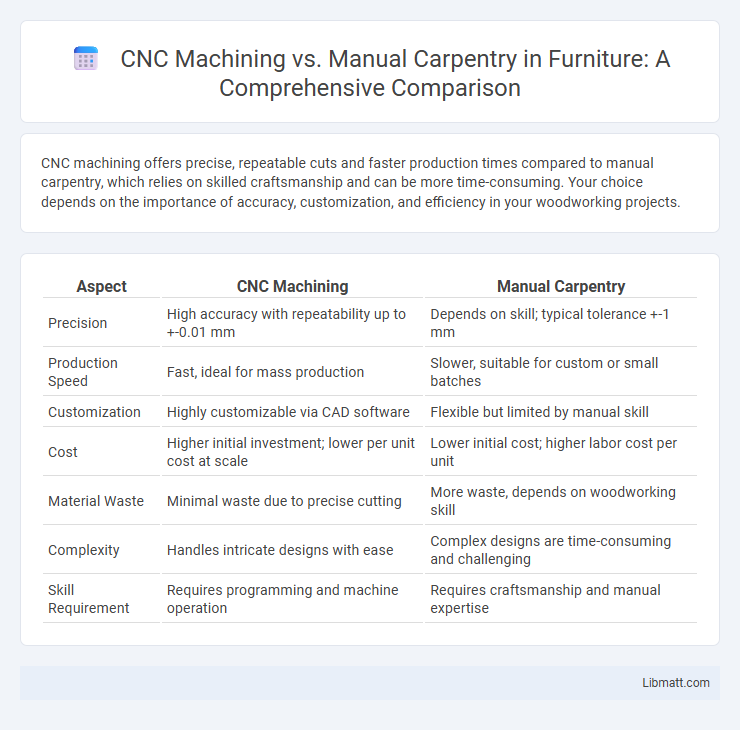

CNC machining offers precise, repeatable cuts and faster production times compared to manual carpentry, which relies on skilled craftsmanship and can be more time-consuming. Your choice depends on the importance of accuracy, customization, and efficiency in your woodworking projects.

Table of Comparison

| Aspect | CNC Machining | Manual Carpentry |

|---|---|---|

| Precision | High accuracy with repeatability up to +-0.01 mm | Depends on skill; typical tolerance +-1 mm |

| Production Speed | Fast, ideal for mass production | Slower, suitable for custom or small batches |

| Customization | Highly customizable via CAD software | Flexible but limited by manual skill |

| Cost | Higher initial investment; lower per unit cost at scale | Lower initial cost; higher labor cost per unit |

| Material Waste | Minimal waste due to precise cutting | More waste, depends on woodworking skill |

| Complexity | Handles intricate designs with ease | Complex designs are time-consuming and challenging |

| Skill Requirement | Requires programming and machine operation | Requires craftsmanship and manual expertise |

Introduction to CNC Machining and Manual Carpentry

CNC machining utilizes computer-controlled tools for precision cutting and shaping of materials, enabling high repeatability and complex designs in manufacturing. Manual carpentry relies on skilled artisans using hand tools and traditional techniques to craft wood products, allowing for customization and intricate detailing. Both methods serve unique purposes, with CNC machining excelling in efficiency and consistency, while manual carpentry offers artistic flexibility and craftsmanship.

Precision and Accuracy in Production

CNC machining achieves unparalleled precision and accuracy through computer-controlled processes that minimize human error and ensure consistent replication of complex designs. Manual carpentry relies on skilled craftsmanship but is inherently limited by human variability, resulting in less uniformity and potential measurement discrepancies. Industrial applications requiring tight tolerances and high repeatability predominantly favor CNC machining for superior production quality.

Speed and Efficiency of Workflow

CNC machining delivers significantly faster production speeds by automating precise, repeatable cuts that minimize human error and reduce material waste. Manual carpentry relies heavily on skilled craftspeople, resulting in longer production times and variability in output quality. The efficiency of CNC workflows enhances scalability and consistency, making it ideal for high-volume manufacturing compared to the slower, labor-intensive nature of manual woodworking.

Flexibility in Design and Customization

CNC machining offers superior flexibility in design and customization, enabling precise replication of complex patterns and rapid modifications through computer-aided programming. Manual carpentry relies heavily on artisan skill, allowing for unique, handcrafted adjustments but limited scalability and repeatability. The integration of CAD data in CNC processes ensures consistent, high-quality outputs even for intricate custom projects.

Skill Requirements and Learning Curve

CNC machining requires specialized technical knowledge in software programming and machine operation, demanding a steeper initial learning curve compared to manual carpentry. Manual carpentry relies heavily on hands-on craftsmanship and traditional skills that develop gradually through practical experience. Your ability to quickly adapt to digital tools can accelerate proficiency in CNC machining, while manual carpentry emphasizes manual dexterity and intuition gained over time.

Cost Comparison: Initial Investment and Maintenance

CNC machining requires a higher initial investment due to advanced computer-controlled equipment and software, whereas manual carpentry demands lower upfront costs with traditional hand tools. Maintenance expenses for CNC machines include software updates, calibration, and specialized repairs, often exceeding the relatively minimal upkeep of manual tools. Over time, CNC machines can reduce labor costs and improve efficiency, potentially offsetting the higher initial and maintenance expenses compared to manual carpentry.

Material Compatibility and Limitations

CNC machining excels in working with a wide range of materials including metals, plastics, and composite materials, offering precise cuts and complex shapes that manual carpentry can't easily achieve. Manual carpentry is typically limited to wood and softer materials, where intricate detailing depends heavily on the craftsman's skill and experience. Your choice between CNC machining and manual carpentry should consider the material compatibility and the complexity of the design to achieve optimal results.

Quality and Consistency of Output

CNC machining delivers superior quality and consistency by using precise computer controls to produce identical parts with tight tolerances, minimizing human error common in manual carpentry. Unlike manual carpentry, where output quality can vary based on the craftsman's skill and fatigue, CNC machining ensures repeatable, high-precision results every time. Your projects benefit from uniform components that maintain structural integrity and aesthetic standards across large production runs.

Environmental Impact and Sustainability

CNC machining offers increased material efficiency and reduced waste compared to manual carpentry, minimizing environmental impact through precise cutting and optimized resource use. Energy consumption in CNC processes is often lower due to automation and less rework, supporting sustainable manufacturing. Your choice of CNC machining can contribute to a greener production cycle by reducing timber waste and enabling better recycling practices.

Choosing the Right Method for Your Project

CNC machining offers unmatched precision and efficiency, making it ideal for projects requiring intricate details and repeatable accuracy. Manual carpentry allows for greater flexibility and craftsmanship, perfect for custom, small-scale work or unique designs that benefit from a human touch. Your choice depends on project scale, complexity, and desired finish, balancing technology and artistry to achieve optimal results.

CNC machining vs manual carpentry Infographic

libmatt.com

libmatt.com