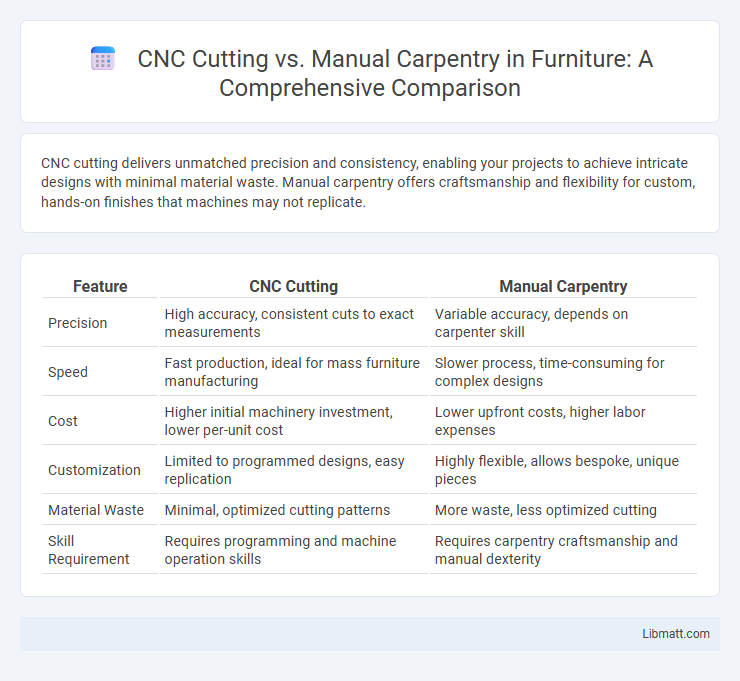

CNC cutting delivers unmatched precision and consistency, enabling your projects to achieve intricate designs with minimal material waste. Manual carpentry offers craftsmanship and flexibility for custom, hands-on finishes that machines may not replicate.

Table of Comparison

| Feature | CNC Cutting | Manual Carpentry |

|---|---|---|

| Precision | High accuracy, consistent cuts to exact measurements | Variable accuracy, depends on carpenter skill |

| Speed | Fast production, ideal for mass furniture manufacturing | Slower process, time-consuming for complex designs |

| Cost | Higher initial machinery investment, lower per-unit cost | Lower upfront costs, higher labor expenses |

| Customization | Limited to programmed designs, easy replication | Highly flexible, allows bespoke, unique pieces |

| Material Waste | Minimal, optimized cutting patterns | More waste, less optimized cutting |

| Skill Requirement | Requires programming and machine operation skills | Requires carpentry craftsmanship and manual dexterity |

Introduction to CNC Cutting and Manual Carpentry

CNC cutting uses computer-controlled machines to precisely shape materials based on digital designs, allowing for consistent accuracy and faster production times. Manual carpentry relies on traditional hand tools and skilled craftsmanship, offering a personalized touch and flexibility for custom projects. Your choice between these methods depends on the balance of efficiency, precision, and artisanal quality required for your project.

Defining CNC Cutting: Precision Through Technology

CNC cutting utilizes computer numerical control technology to deliver precise, repeatable cuts in woodworking and manufacturing, outperforming manual carpentry in accuracy and efficiency. This automated method ensures consistent quality by following exact digital designs, reducing material waste and production time. Your projects benefit from CNC cutting's ability to produce complex shapes and detailed patterns that are difficult to achieve manually.

Manual Carpentry: Traditional Craftsmanship Explained

Manual carpentry involves skilled artisans using hand tools and traditional techniques to shape and assemble wood, emphasizing precision and artistry. This craftsmanship allows for intricate detailing and customization that machines may not easily replicate. Despite longer production times, manual carpentry delivers unique, high-quality woodwork with a personal touch valued in bespoke projects.

Speed and Efficiency: CNC Machines vs Hand Tools

CNC cutting significantly outpaces manual carpentry by automating precise cuts at high speeds, reducing production time while maintaining consistent quality. Your projects benefit from streamlined workflows and minimized material waste due to the machine's programmed accuracy. In contrast, hand tools require skilled craftsmanship and longer labor hours, making CNC machines the preferred choice for efficiency in both small and large-scale woodworking tasks.

Material Compatibility in CNC and Manual Carpentry

CNC cutting offers exceptional material compatibility, efficiently processing a wide range of materials including hardwood, softwood, plywood, MDF, and even non-wood materials like plastics and metals with high precision. Manual carpentry, while versatile, often requires skilled craftsmen to adapt techniques for different materials and may face limitations with harder or composite materials due to tool wear and manual dexterity constraints. CNC technology's ability to maintain consistent cutting quality across diverse substrates significantly enhances production efficiency and material utilization compared to traditional manual methods.

Accuracy and Consistency: Comparing Output Quality

CNC cutting delivers superior accuracy and consistency by utilizing computer-controlled precision, reducing human error and producing identical cuts every time. Manual carpentry relies heavily on the skill and experience of the craftsman, which can result in variability and occasional imperfections. CNC technology enhances output quality by maintaining exact specifications across large production runs, ensuring uniformity that manual methods often struggle to achieve.

Design Flexibility: Complex Patterns and Customization

CNC cutting offers superior design flexibility by enabling the creation of intricate and precise patterns that manual carpentry struggles to replicate consistently. Your projects benefit from customizable, complex designs with exact dimensions produced efficiently through automated programming. Manual carpentry, while valuable for unique craftsmanship, often limits the complexity and repeatability achievable in detailed customization.

Labor Requirements and Skill Levels

CNC cutting significantly reduces labor requirements by automating precise cuts, allowing a single operator to manage complex designs with minimal manual intervention. Manual carpentry demands higher skill levels and physical effort, as craftsmen rely on experience and steady hands to execute accurate cuts and joinery. Your project efficiency can increase with CNC technology, especially when consistent quality and repeatability are essential.

Cost Analysis: Upfront Investment and Long-Term Value

CNC cutting requires a significantly higher upfront investment due to the cost of advanced machinery and software, but it offers greater precision and efficiency, reducing material waste and labor expenses over time. Manual carpentry involves lower initial costs but often results in longer project timelines and higher labor costs, impacting overall profitability. Over the long term, CNC cutting provides better value through increased production speed, consistent quality, and scalability in woodworking operations.

Environmental Impact and Sustainability Considerations

CNC cutting significantly reduces material waste by optimizing cutting patterns with precision software, leading to more sustainable resource use compared to manual carpentry, which often produces excess offcuts. Energy consumption in CNC machines can be lower per unit of output due to automation and efficiency, while manual processes rely heavily on human labor and can result in inconsistent waste levels. Choosing CNC cutting supports your commitment to environmental responsibility by minimizing waste and enhancing the sustainability of woodworking projects.

CNC Cutting vs Manual Carpentry Infographic

libmatt.com

libmatt.com