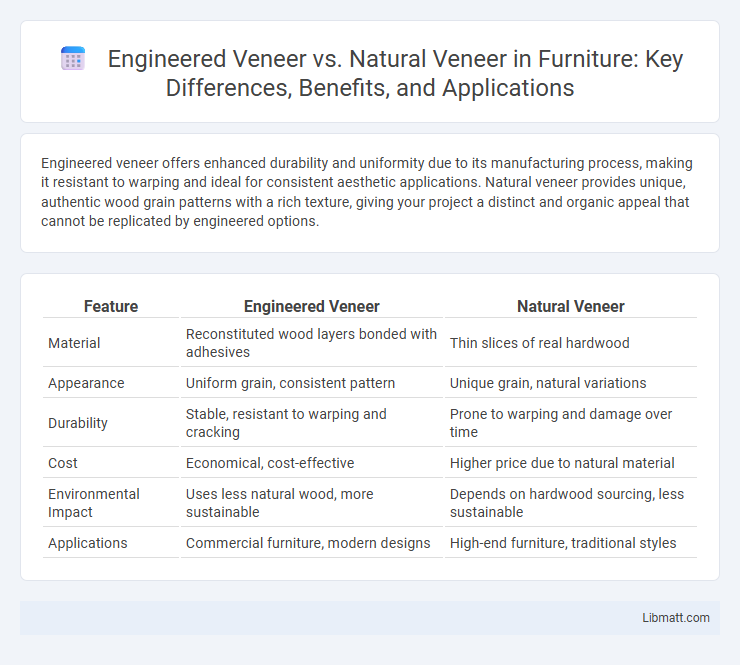

Engineered veneer offers enhanced durability and uniformity due to its manufacturing process, making it resistant to warping and ideal for consistent aesthetic applications. Natural veneer provides unique, authentic wood grain patterns with a rich texture, giving your project a distinct and organic appeal that cannot be replicated by engineered options.

Table of Comparison

| Feature | Engineered Veneer | Natural Veneer |

|---|---|---|

| Material | Reconstituted wood layers bonded with adhesives | Thin slices of real hardwood |

| Appearance | Uniform grain, consistent pattern | Unique grain, natural variations |

| Durability | Stable, resistant to warping and cracking | Prone to warping and damage over time |

| Cost | Economical, cost-effective | Higher price due to natural material |

| Environmental Impact | Uses less natural wood, more sustainable | Depends on hardwood sourcing, less sustainable |

| Applications | Commercial furniture, modern designs | High-end furniture, traditional styles |

Introduction to Veneers: Engineered vs Natural

Engineered veneer consists of thin layers of wood bonded together under heat and pressure, ensuring greater stability and resistance to warping compared to natural veneer. Natural veneer is crafted by slicing thin sheets from solid wood logs, preserving the authentic grain and unique patterns inherent to each species. The choice between engineered and natural veneer impacts durability, appearance, and cost considerations for furniture and interior applications.

What Is Engineered Veneer?

Engineered veneer consists of thin layers of wood bonded together with adhesives to create a stable, uniform sheet that replicates the appearance of natural wood. Unlike natural veneer, which is sliced directly from hardwood logs, engineered veneer undergoes a manufacturing process that enhances durability and reduces susceptibility to warping. Choosing engineered veneer for your projects ensures consistent grain patterns and increased resistance to environmental changes.

What Is Natural Veneer?

Natural veneer is a thin slice of real wood sliced from logs, showcasing unique grain patterns and natural variations that reflect the tree's original texture and color. It is prized for its authenticity and aesthetic appeal in high-end furniture and cabinetry, providing a luxurious, organic finish. Unlike engineered veneer, natural veneer maintains the wood's natural imperfections and character, making each piece distinctive.

Manufacturing Process: Engineered vs Natural Veneer

Engineered veneer is produced by layering thin slices of wood or wood fibers bonded with adhesives under heat and pressure, creating a uniform, stable sheet ideal for consistent application. Natural veneer is sliced directly from logs, preserving the wood's unique grain patterns but resulting in variations and potential imperfections. The manufacturing process of engineered veneer allows for greater control over thickness and appearance, whereas natural veneer relies on the original log's characteristics.

Appearance and Aesthetics Comparison

Engineered veneer offers a consistent and uniform appearance due to its layered construction, making it ideal for modern designs requiring precise patterns and color stability. Natural veneer displays unique grain patterns and color variations that enhance aesthetic richness and authenticity, appealing to those seeking a traditional or organic look. While engineered veneer resists fading and wear, natural veneer provides unmatched natural beauty, with imperfections that contribute to its character.

Durability and Performance Differences

Engineered veneer offers enhanced durability and resistance to warping, cracking, and moisture damage compared to natural veneer, due to its multi-layer construction bonded under heat and pressure. Natural veneer, while providing unique and authentic wood grain patterns, is more susceptible to environmental changes, potentially leading to dimensional instability over time. Engineered veneer's consistent performance in variable conditions makes it a preferred choice for applications demanding long-term structural integrity and low maintenance.

Environmental Impact and Sustainability

Engineered veneer offers a more sustainable alternative to natural veneer by maximizing wood usage and reducing waste through its lamination of thin wood layers bonded with adhesives. Natural veneer requires harvesting larger portions of valuable trees, contributing to deforestation and habitat loss, whereas engineered veneer often utilizes fast-growing, plantation-sourced wood, minimizing environmental impact. Your choice of engineered veneer supports sustainable forestry practices and helps lower the carbon footprint compared to traditional natural veneer.

Cost Comparison: Engineered vs Natural Veneer

Engineered veneer generally costs less than natural veneer due to its manufacturing process, which uses thin layers of wood bonded over plywood or MDF, reducing the amount of high-quality hardwood required. Natural veneer, sourced directly from premium logs, commands higher prices because of the rarity and grain uniqueness of each sheet. Budget-conscious projects often favor engineered veneer for its affordability without compromising aesthetic appeal.

Applications and Common Uses

Engineered veneer is widely used in commercial settings and high-traffic areas due to its consistent appearance, durability, and resistance to warping, making it ideal for furniture, cabinetry, and wall panels. Natural veneer retains unique grain patterns and textures preferred in luxury interiors and restoration projects, providing an authentic wood look for doors, furniture, and architectural details. You can choose engineered veneer for budget-friendly, uniform finishes or natural veneer when aiming for traditional aesthetics and premium craftsmanship.

Choosing the Right Veneer for Your Project

Engineered veneer offers consistent grain patterns, enhanced durability, and better resistance to moisture compared to natural veneer, making it ideal for high-traffic or humid environments. Natural veneer provides unique, authentic wood aesthetics with intricate variations that enhance the character and value of your project. Your choice depends on the balance between aesthetic preferences, environmental conditions, and long-term maintenance requirements.

engineered veneer vs natural veneer Infographic

libmatt.com

libmatt.com