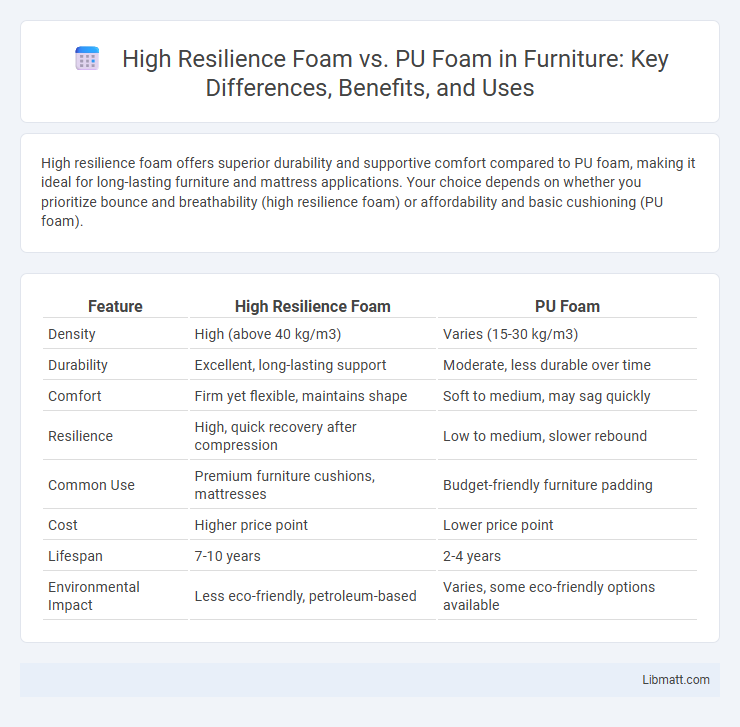

High resilience foam offers superior durability and supportive comfort compared to PU foam, making it ideal for long-lasting furniture and mattress applications. Your choice depends on whether you prioritize bounce and breathability (high resilience foam) or affordability and basic cushioning (PU foam).

Table of Comparison

| Feature | High Resilience Foam | PU Foam |

|---|---|---|

| Density | High (above 40 kg/m3) | Varies (15-30 kg/m3) |

| Durability | Excellent, long-lasting support | Moderate, less durable over time |

| Comfort | Firm yet flexible, maintains shape | Soft to medium, may sag quickly |

| Resilience | High, quick recovery after compression | Low to medium, slower rebound |

| Common Use | Premium furniture cushions, mattresses | Budget-friendly furniture padding |

| Cost | Higher price point | Lower price point |

| Lifespan | 7-10 years | 2-4 years |

| Environmental Impact | Less eco-friendly, petroleum-based | Varies, some eco-friendly options available |

Introduction to High Resilience Foam and PU Foam

High resilience (HR) foam offers superior elasticity and durability compared to traditional polyurethane (PU) foam, making it ideal for applications requiring long-term comfort and support. PU foam, commonly used in furniture cushioning and mattresses, provides a softer feel but tends to compress and lose shape over time. The advanced polymer structure of HR foam ensures enhanced airflow and resilience, distinguishing it from the conventional PU foam's lower density and quicker wear.

Composition and Manufacturing Process

High resilience foam is primarily composed of polyurethane with a higher density and enhanced elastic properties achieved through specialized polymer formulations and controlled chemical reactions during manufacturing, resulting in greater durability and support. PU foam (polyurethane foam) is produced by mixing polyols and diisocyanates, which react to form a flexible cellular structure; variations in density and firmness depend on additive concentrations and curing conditions. The manufacturing process of high resilience foam involves precise temperature and pressure control to optimize cell structure for improved air circulation, while standard PU foam typically undergoes simpler production methods focusing on cost-efficiency.

Key Physical Properties

High resilience foam offers superior elasticity and better breathability compared to PU foam, making it ideal for applications requiring enhanced support and durability. Its open-cell structure provides exceptional airflow, while PU foam typically has a denser composition with lower elasticity and slower recovery time. Your choice between these foams should consider factors like compression strength, tensile strength, and lifespan depending on the specific comfort and durability needs.

Comfort and Support Comparison

High resilience foam provides superior comfort and support due to its higher density and faster recovery rate, allowing it to adapt quickly to your body shape and movements. PU foam, while generally more affordable, tends to offer less durability and support, compressing more quickly under weight which can reduce comfort over time. Choosing high resilience foam ensures enhanced pressure relief and long-lasting cushioning for sustained comfort.

Durability and Longevity

High resilience foam offers superior durability and longevity compared to PU foam due to its enhanced ability to retain shape and resist sagging over time. The open-cell structure of high resilience foam allows better airflow, reducing moisture buildup and material degradation. PU foam tends to compress and lose cushioning faster under continuous use, making high resilience foam the preferred choice for applications requiring long-lasting comfort and support.

Applications in Furniture and Bedding

High resilience foam offers superior support and durability compared to standard PU foam, making it ideal for high-traffic furniture such as sofas, chairs, and mattresses where long-term comfort and shape retention are critical. PU foam, while more affordable, tends to compress faster and is commonly used in budget-friendly bedding products and less frequently used furniture pieces. The enhanced air circulation and elasticity of high resilience foam also contribute to better pressure distribution and breathability in mattresses and cushions, improving overall sleep quality.

Cost and Affordability

High resilience (HR) foam typically costs more than standard polyurethane (PU) foam due to its superior durability and support properties, making it a premium choice for long-lasting comfort. PU foam is more affordable and widely used in budget-conscious applications but may compress and deteriorate faster over time. Choosing between HR and PU foam depends on balancing initial investment against longevity and performance needs.

Environmental Impact and Sustainability

High resilience foam (HR foam) typically has a lower environmental impact than standard PU foam due to its longer lifespan and better durability, which reduces the frequency of replacement and waste. HR foam often contains higher-density materials, making it more sustainable by minimizing resource consumption and enhancing energy efficiency during production. Choosing HR foam for Your furniture can contribute to a more eco-friendly lifestyle by supporting products with improved recyclability and reduced chemical emissions.

Consumer Preferences and Reviews

High resilience foam offers superior durability and support compared to PU foam, making it a preferred choice among consumers seeking long-lasting comfort. Reviews highlight high resilience foam's ability to maintain its shape and provide consistent support over time, whereas PU foam often receives feedback about quicker compression and reduced comfort. Your decision may lean towards high resilience foam if you prioritize resilience and sustained cushioning in mattresses or cushions.

Choosing the Right Foam for Your Needs

High resilience foam offers superior durability, elasticity, and support compared to traditional PU foam, making it ideal for applications requiring long-lasting comfort and cushioning. PU foam, while more affordable and widely available, tends to compress faster and may not provide the same level of resilience in high-use environments. Understanding your specific needs for comfort, longevity, and budget will help you select the foam that best suits your requirements.

high resilience foam vs PU foam Infographic

libmatt.com

libmatt.com