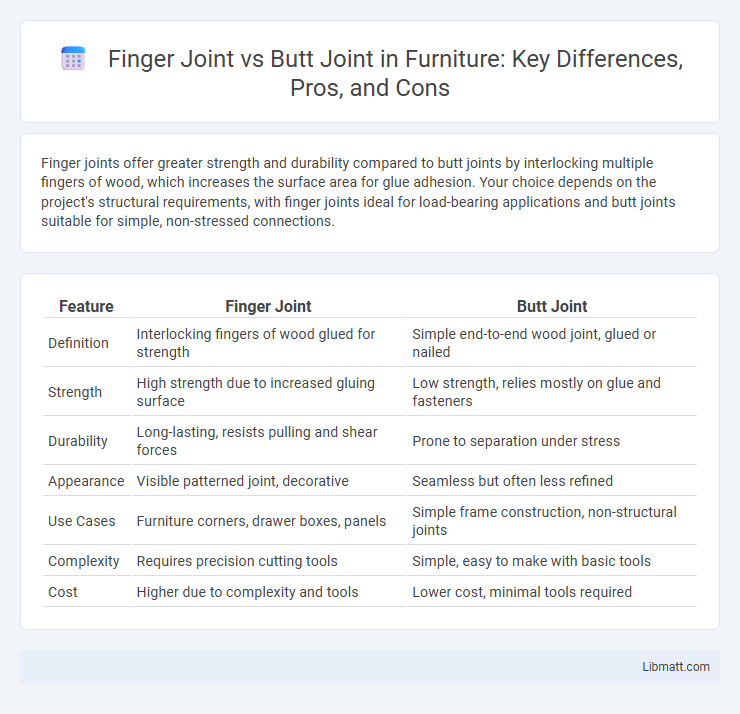

Finger joints offer greater strength and durability compared to butt joints by interlocking multiple fingers of wood, which increases the surface area for glue adhesion. Your choice depends on the project's structural requirements, with finger joints ideal for load-bearing applications and butt joints suitable for simple, non-stressed connections.

Table of Comparison

| Feature | Finger Joint | Butt Joint |

|---|---|---|

| Definition | Interlocking fingers of wood glued for strength | Simple end-to-end wood joint, glued or nailed |

| Strength | High strength due to increased gluing surface | Low strength, relies mostly on glue and fasteners |

| Durability | Long-lasting, resists pulling and shear forces | Prone to separation under stress |

| Appearance | Visible patterned joint, decorative | Seamless but often less refined |

| Use Cases | Furniture corners, drawer boxes, panels | Simple frame construction, non-structural joints |

| Complexity | Requires precision cutting tools | Simple, easy to make with basic tools |

| Cost | Higher due to complexity and tools | Lower cost, minimal tools required |

Introduction to Finger Joint and Butt Joint

Finger joints and butt joints are common woodworking techniques used to join pieces of wood. Finger joints involve interlocking rectangular "fingers" cut into the ends of two boards, providing increased surface area for glue and enhanced strength. Butt joints simply join two pieces of wood end-to-end without additional shaping, relying primarily on adhesives or mechanical fasteners for stability.

Definition and Overview of Finger Joint

A finger joint, also known as a box joint, is a woodworking technique where interlocking rectangular "fingers" of wood are cut into two pieces, creating a strong and durable connection when glued together. This joint increases the surface area for adhesive, resulting in enhanced mechanical strength compared to a simple butt joint, where two flat surfaces are joined without interlocking features. Commonly used in cabinet making and drawer construction, the finger joint provides both structural integrity and aesthetic appeal.

Definition and Overview of Butt Joint

A butt joint is a simple woodworking or metalworking technique where two pieces are joined by placing their flat ends together without any overlapping or interlocking. This joint is commonly used for basic frame construction and simple repairs due to its ease of assembly and minimal material removal. While it lacks inherent strength compared to finger joints, reinforcement methods like screws, nails, or adhesives can enhance its durability in various applications.

How Finger Joints Are Made

Finger joints are created by cutting interlocking rectangular projections into the ends of two pieces of wood, which fit together like interlaced fingers. This precise machining process typically uses a table saw, router, or finger joint jig to ensure tight, strong connections with increased surface area for gluing. Your woodworking projects benefit from finger joints' enhanced durability and resistance to twisting compared to simple butt joints.

How Butt Joints Are Constructed

Butt joints are constructed by simply aligning two flat edges of wood and fastening them together using nails, screws, or glue without any interlocking shapes. This type of joint relies heavily on external fasteners or adhesives to maintain strength since the surfaces lack mechanical bonding features. You can create a quick and straightforward connection, but it often requires reinforcement to achieve durability compared to more complex joints like finger joints.

Strength Comparison: Finger Joint vs Butt Joint

Finger joints provide significantly greater strength than butt joints due to their interlocking design, which increases surface area for adhesive bonding and resists shear and tensile forces more effectively. Butt joints rely solely on end-to-end adhesive or fasteners, making them weaker under stress and more prone to failure. Your projects benefit from finger joints when durability and load-bearing capacity are critical.

Applications and Common Uses

Finger joints are commonly used in woodworking and furniture manufacturing due to their strong interlocking design, making them ideal for assembling boxes, drawers, and cabinet frames. Butt joints are simpler and often found in rough framing, basic carpentry, and temporary structures where speed and ease of assembly are more critical than strength. Finger joints offer enhanced durability for load-bearing applications, while butt joints are preferred for non-structural, quick, and cost-effective projects.

Advantages of Finger Joints

Finger joints offer superior strength and durability compared to butt joints, providing increased surface area for gluing and enhanced load-bearing capacity. These joints create interlocking fingers that resist tension and shear forces, making them ideal for structural applications and furniture construction. Your projects will benefit from improved alignment and a more aesthetically pleasing finish when using finger joints instead of butt joints.

Advantages of Butt Joints

Butt joints offer simplicity and speed in woodworking, requiring minimal tools and skills for assembly. Their straightforward design allows for easy alignment and quick connection of materials, making them cost-effective for basic framing and construction projects. Despite lower strength compared to finger joints, butt joints can be reinforced with screws, nails, or adhesives to enhance durability.

Choosing the Right Joint for Your Project

Choosing the right joint for your project depends on the required strength and appearance; finger joints offer superior mechanical strength and a larger gluing surface ideal for load-bearing applications, while butt joints are simpler and faster to execute but provide less durability. Finger joints are commonly used in cabinetry and furniture where precision and durability are essential, whereas butt joints suit quick framing or non-structural components. Evaluating project demands, wood species, and tools available will help determine whether the interlocking design of finger joints or the straightforward nature of butt joints best aligns with your woodworking needs.

finger joint vs butt joint Infographic

libmatt.com

libmatt.com