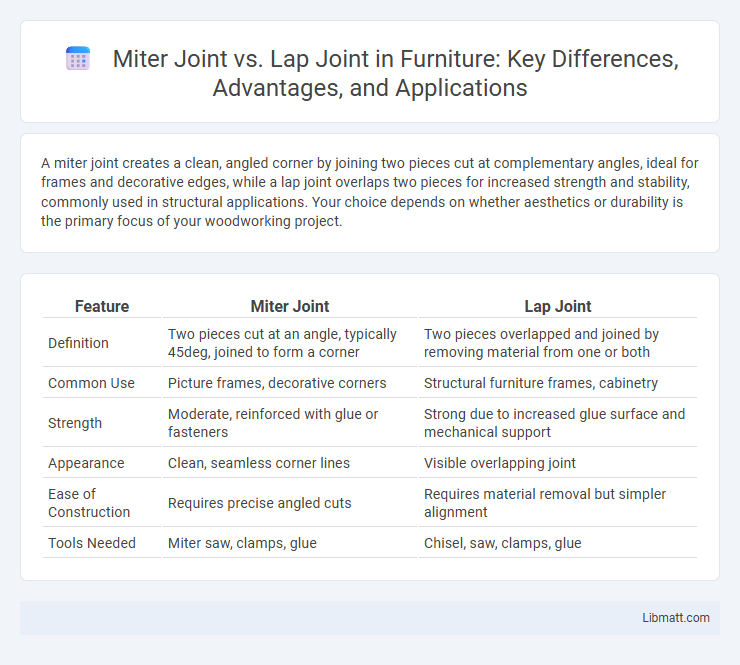

A miter joint creates a clean, angled corner by joining two pieces cut at complementary angles, ideal for frames and decorative edges, while a lap joint overlaps two pieces for increased strength and stability, commonly used in structural applications. Your choice depends on whether aesthetics or durability is the primary focus of your woodworking project.

Table of Comparison

| Feature | Miter Joint | Lap Joint |

|---|---|---|

| Definition | Two pieces cut at an angle, typically 45deg, joined to form a corner | Two pieces overlapped and joined by removing material from one or both |

| Common Use | Picture frames, decorative corners | Structural furniture frames, cabinetry |

| Strength | Moderate, reinforced with glue or fasteners | Strong due to increased glue surface and mechanical support |

| Appearance | Clean, seamless corner lines | Visible overlapping joint |

| Ease of Construction | Requires precise angled cuts | Requires material removal but simpler alignment |

| Tools Needed | Miter saw, clamps, glue | Chisel, saw, clamps, glue |

Introduction to Miter Joint and Lap Joint

Miter joints connect two pieces of material cut at an angle, typically 45 degrees, forming a clean corner often used in picture frames and trim work. Lap joints overlap two pieces, providing strong mechanical connection commonly found in woodworking and metal fabrication. Your choice between these joints depends on the desired strength and appearance for the project.

What is a Miter Joint?

A miter joint is a woodworking technique where two pieces are cut at an angle, typically 45 degrees, to form a corner, commonly used in picture frames and molding. This joint offers a clean, seamless appearance by hiding the end grain, enhancing the aesthetic appeal of the finished product. Despite its visual advantages, the miter joint often requires reinforcement with glue, nails, or splines to ensure structural strength.

What is a Lap Joint?

A lap joint is a type of connection where two overlapping pieces of material, usually wood or metal, are joined together by welding, adhesive, or mechanical fasteners. This joint provides strong structural integrity due to the increased surface area for bonding or fastening. Lap joints are commonly used in framing, carpentry, and metalworking for their simplicity and durability.

Key Differences Between Miter and Lap Joints

Miter joints feature angled cuts, typically at 45 degrees, that join two pieces to form a clean corner, commonly used in frames and trim work for aesthetic appeal. Lap joints overlap two pieces, providing greater surface area for adhesive or fasteners, resulting in increased strength and durability ideal for structural applications. The key differences lie in their construction methods, visual appearance, and load-bearing capacity, with miter joints prioritizing seamless edges and lap joints emphasizing mechanical strength.

Advantages of Miter Joints

Miter joints provide a clean, seamless appearance by joining two pieces at a precise 45-degree angle, making them ideal for frames and decorative trim. They offer enhanced aesthetic appeal without visible end grain, which enhances the visual continuity of your project. Additionally, miter joints are easier to conceal gaps and can be reinforced with splines or biscuits for added strength.

Advantages of Lap Joints

Lap joints offer superior mechanical strength due to their increased overlapping surface area, making them ideal for applications requiring enhanced load-bearing capacity. They provide excellent alignment and can easily accommodate welding, riveting, or bolting, ensuring reliable and durable connections in woodworking and metalworking. The simplicity of lap joint fabrication reduces production time and cost compared to more complex joints like miter joints.

Common Applications of Miter Joints

Miter joints are commonly used in picture frames, door frames, and various types of trim and molding where a clean, angled edge is essential for aesthetic appeal. These joints provide a seamless corner finish that enhances the overall look of cabinetry and furniture, making them ideal for decorative woodworking projects. Your choice of a miter joint will ensure precise, visually appealing connections in applications requiring sharp, accurate angles.

Common Applications of Lap Joints

Lap joints are widely used in woodworking, metalworking, and construction due to their strength and ease of assembly. Common applications include framing, cabinetry, and automotive bodywork where overlapping materials provide enhanced load distribution. This joint is favored in situations requiring quick fabrication and moderate load resistance without complex tools.

Strength and Durability Comparison

Miter joints typically offer a cleaner appearance but are generally less strong and durable compared to lap joints due to their reliance on adhesive and precise angle cuts, which can be prone to splitting under stress. Lap joints provide superior strength and durability because they overlap material, increasing surface area for bonding or fasteners, making them ideal for structural applications. The enhanced load distribution and mechanical fastening options in lap joints ensure better resistance to shear and tension forces over time.

Choosing the Right Joint: Miter vs. Lap

Choosing the right joint depends on your project's strength and aesthetic needs; miter joints offer a clean, angled appearance ideal for picture frames and decorative trim, while lap joints provide superior mechanical strength suitable for structural applications. Miter joints require precise cutting and reinforcement to prevent splitting, whereas lap joints overlap two pieces, distributing stress more evenly for durability. Your selection should balance visual appeal with the necessary load-bearing capacity to ensure both function and design integrity.

Miter joint vs lap joint Infographic

libmatt.com

libmatt.com