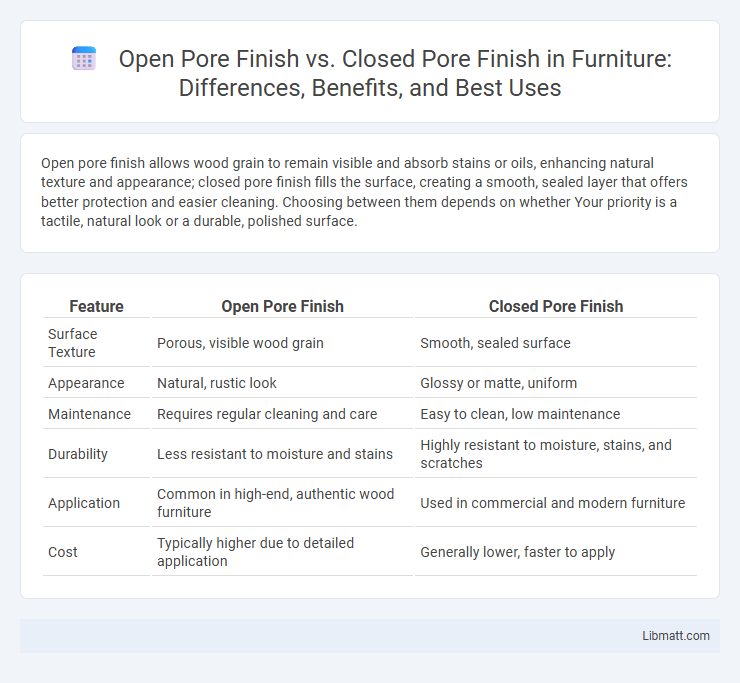

Open pore finish allows wood grain to remain visible and absorb stains or oils, enhancing natural texture and appearance; closed pore finish fills the surface, creating a smooth, sealed layer that offers better protection and easier cleaning. Choosing between them depends on whether Your priority is a tactile, natural look or a durable, polished surface.

Table of Comparison

| Feature | Open Pore Finish | Closed Pore Finish |

|---|---|---|

| Surface Texture | Porous, visible wood grain | Smooth, sealed surface |

| Appearance | Natural, rustic look | Glossy or matte, uniform |

| Maintenance | Requires regular cleaning and care | Easy to clean, low maintenance |

| Durability | Less resistant to moisture and stains | Highly resistant to moisture, stains, and scratches |

| Application | Common in high-end, authentic wood furniture | Used in commercial and modern furniture |

| Cost | Typically higher due to detailed application | Generally lower, faster to apply |

Introduction to Pore Finishes in Woodworking

Open pore finish enhances wood's natural texture by allowing the grain to remain visible and tactile, providing a rustic and authentic appearance. Closed pore finish, on the other hand, fills the wood's pores to create a smooth, sealed surface ideal for a polished and uniform look. Your choice between these finishes directly impacts the wood's durability, moisture resistance, and aesthetic appeal for your project.

What Is an Open Pore Finish?

An open pore finish is a type of surface treatment where the natural texture and pores of wood or other materials remain exposed, allowing for better absorption of stains and oils that enhance the material's character. This finish is ideal for achieving a more authentic, tactile feel and is often preferred in furniture and flooring to highlight natural grain patterns. Your choice of an open pore finish supports breathability and a rustic aesthetic, contrasting with the smoothness of closed pore finishes.

Understanding Closed Pore Finishes

Closed pore finishes feature a smooth, non-porous surface that resists moisture and stains, making them ideal for high-traffic areas and surfaces exposed to liquids. Unlike open pore finishes, closed pore finishes seal the wood's natural grain, providing enhanced durability and easier maintenance. This finish is commonly used in furniture, cabinetry, and flooring where long-lasting protection and a sleek appearance are essential.

Key Differences Between Open and Closed Pore Finishes

Open pore finishes allow the natural texture and grain of wood to remain visible, providing a more tactile and rustic appearance with enhanced breathability, which helps prevent moisture buildup. Closed pore finishes create a smooth, sealed surface by filling the pores, offering increased protection against stains and moisture, resulting in a more durable and glossy look. The choice between open and closed pore finishes depends on the desired aesthetic, maintenance level, and environmental exposure of the wood surface.

Visual and Tactile Effects on Wood Surfaces

Open pore finish enhances the natural grain and texture of wood by allowing the pores to remain visible and feel rougher to the touch, creating a more rustic and authentic appearance. Closed pore finish fills and seals the wood pores, resulting in a smooth, glossy surface that emphasizes uniformity and durability. Visual appeal varies with open pore finishes offering a matte or satin look, while closed pore finishes provide a sleek, polished effect ideal for modern or formal settings.

Durability and Protection Aspects Compared

Open pore finishes allow wood to breathe by penetrating deeply into the grain, offering enhanced moisture resistance and long-lasting durability against environmental stress. Closed pore finishes create a solid barrier on the surface, providing superior protection against scratches, stains, and UV damage while preventing water infiltration. Choosing between open pore and closed pore finishes depends on the desired balance between natural wood appearance and maximum surface protection.

Application Techniques for Each Finish

Open pore finish requires techniques such as brushing or wiping on thin layers to allow the wood grain to remain visible and breathable, often applied with a cloth or brush that soaks into the surface. Closed pore finish involves application methods like spraying or rolling multiple layers of sealant or varnish to create a smooth, sealed surface that protects against moisture and prevents absorption. Your choice of application technique will depend on whether you prioritize wood texture visibility and breathability (open pore) or a durable, moisture-resistant coating (closed pore).

Pros and Cons of Open Pore Finishes

Open pore finishes enhance wood's natural texture and allow it to breathe, which can prevent moisture buildup and prolong material lifespan. They are easy to repair and maintain but may absorb stains and dirt more readily, making them less resistant to wear and requiring more frequent upkeep. Their porous nature offers superior adhesion for paints and stains but lacks the robust protective barrier that closed pore finishes provide against water and chemicals.

Advantages and Drawbacks of Closed Pore Finishes

Closed pore finishes provide a smooth, non-porous surface that resists moisture, stains, and dirt penetration, making them ideal for high-traffic areas and surfaces exposed to liquids. Their durability and ease of cleaning significantly reduce maintenance requirements compared to open pore finishes. However, closed pore finishes may lack the natural texture and wood grain visibility that open pore finishes offer, potentially diminishing the aesthetic appeal for applications seeking a more organic look.

Choosing the Right Finish for Your Wood Project

Open pore finish enhances wood's natural texture and allows moisture exchange, ideal for indoor furniture where breathability is desired. Closed pore finish forms a sealed, protective barrier, offering superior resistance to water, stains, and wear, perfect for high-traffic surfaces and outdoor wood projects. Selecting between open and closed pore finishes depends on the wood's intended use, environmental exposure, and desired aesthetic effect.

Open pore finish vs closed pore finish Infographic

libmatt.com

libmatt.com