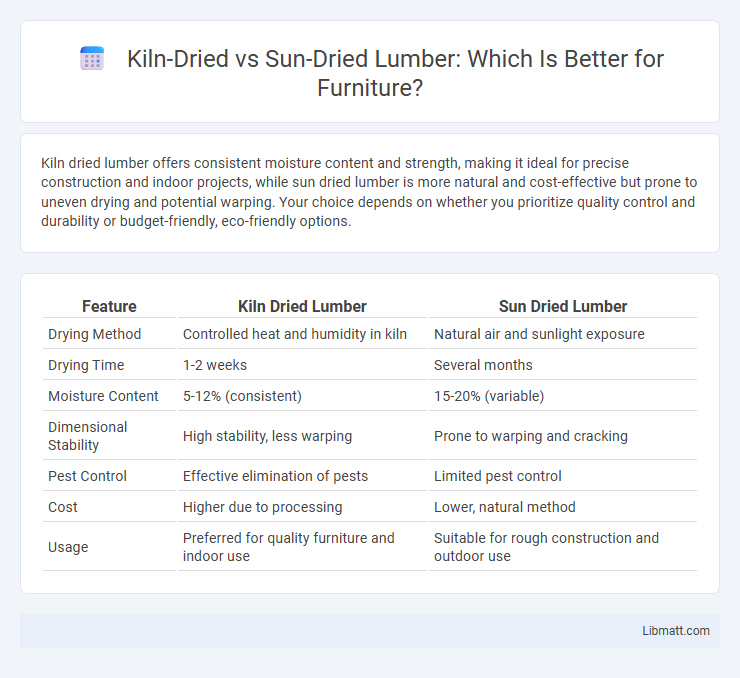

Kiln dried lumber offers consistent moisture content and strength, making it ideal for precise construction and indoor projects, while sun dried lumber is more natural and cost-effective but prone to uneven drying and potential warping. Your choice depends on whether you prioritize quality control and durability or budget-friendly, eco-friendly options.

Table of Comparison

| Feature | Kiln Dried Lumber | Sun Dried Lumber |

|---|---|---|

| Drying Method | Controlled heat and humidity in kiln | Natural air and sunlight exposure |

| Drying Time | 1-2 weeks | Several months |

| Moisture Content | 5-12% (consistent) | 15-20% (variable) |

| Dimensional Stability | High stability, less warping | Prone to warping and cracking |

| Pest Control | Effective elimination of pests | Limited pest control |

| Cost | Higher due to processing | Lower, natural method |

| Usage | Preferred for quality furniture and indoor use | Suitable for rough construction and outdoor use |

Introduction to Lumber Drying Methods

Kiln dried lumber undergoes controlled drying in a specialized oven, ensuring moisture content is reduced to ideal levels quickly and uniformly for stability and strength. Sun dried lumber relies on natural air and sunlight exposure, resulting in slower moisture evaporation and higher variability in drying quality. Kiln drying offers enhanced resistance to warping, decay, and insect infestation compared to sun drying.

What is Kiln Dried Lumber?

Kiln dried lumber refers to wood that has been dried in a controlled, heated environment to reduce its moisture content to a specific level, typically between 6-8%. This process ensures uniform drying, minimizes warping, cracking, and insect infestation, making the wood more stable and durable for construction or woodworking projects. Your choice of kiln dried lumber guarantees better dimensional stability compared to sun dried lumber, which dries unevenly and often retains higher moisture levels.

What is Sun Dried Lumber?

Sun dried lumber is wood that has been naturally dried by exposure to sunlight and air, reducing its moisture content over time without mechanical intervention. This traditional method can take several weeks to months, depending on climate and wood species, resulting in a slower drying process that may retain more natural wood characteristics but with potential risks of uneven drying and warping. Sun dried lumber is often preferred for its eco-friendly approach and reduced energy use compared to kiln dried lumber, which undergoes controlled high-temperature drying.

Drying Process Comparison: Kiln vs Sun

Kiln dried lumber undergoes a controlled drying process using high heat and regulated humidity, resulting in faster moisture removal and consistent quality. Sun dried lumber relies on natural air circulation and sunlight, which can lead to uneven drying and increased risk of defects like warping or cracking. The kiln drying process achieves a moisture content typically between 6-8%, while sun drying often results in higher and less predictable moisture levels.

Moisture Content Differences

Kiln dried lumber typically has a moisture content of 6-8%, resulting in enhanced dimensional stability and reduced risk of warping or cracking. Sun dried lumber usually retains a higher moisture content, often between 12-20%, which can lead to increased shrinkage and susceptibility to insect infestation. Controlling moisture content through kiln drying ensures more predictable performance in construction and woodworking applications.

Impact on Wood Strength and Stability

Kiln dried lumber undergoes controlled heating, reducing moisture content to 6-8%, which significantly enhances wood strength and stability by minimizing warping, cracking, and shrinkage. Sun dried lumber typically retains higher moisture levels, leading to increased susceptibility to deformation and decreased load-bearing capacity. Your choice of kiln dried wood ensures improved performance in structural applications due to its consistent moisture content and durability.

Cost Considerations: Kiln Drying vs Sun Drying

Kiln dried lumber typically costs more upfront due to energy consumption and specialized equipment, but it offers consistent moisture levels and faster drying times, reducing risks of warping or decay. Sun dried lumber is less expensive initially, relying on natural air and sunlight, but may require longer drying periods and careful monitoring to avoid defects. Your choice depends on budget flexibility and project timeline, where kiln drying provides efficiency at a higher cost while sun drying offers a low-cost, slower alternative.

Environmental Impact of Drying Methods

Kiln drying lumber consumes significant energy, often derived from fossil fuels, leading to higher carbon emissions compared to sun drying, which relies on natural solar energy and has minimal environmental impact. However, kiln drying reduces moisture content rapidly, preventing mold growth and insect infestation, which can reduce waste and increase the wood's longevity. Sun drying requires longer periods and space but offers a low-energy alternative that aligns with sustainable forestry practices by minimizing reliance on non-renewable resources.

Common Uses for Each Drying Method

Kiln dried lumber is commonly used for indoor construction, furniture making, and cabinetry due to its consistent moisture content and reduced risk of warping or insect infestation. Sun dried lumber is often utilized for outdoor projects, fencing, and rustic furniture where natural drying methods are preferred and slight variations in moisture content are acceptable. Your choice depends on the desired application, with kiln drying offering precision for indoor uses and sun drying providing an economical option for outdoor or less moisture-sensitive projects.

Which Drying Method is Best for Your Project?

Kiln dried lumber offers consistent moisture content, faster drying times, and better resistance to mold and insect damage, making it ideal for precise woodworking projects and indoor use. Sun dried lumber, though more cost-effective and environmentally friendly, often results in uneven moisture levels and longer drying periods, which may cause warping or cracking. Choose kiln dried lumber for your project when durability and dimensional stability are critical, especially in cabinetry or furniture making.

kiln dried vs sun dried lumber Infographic

libmatt.com

libmatt.com