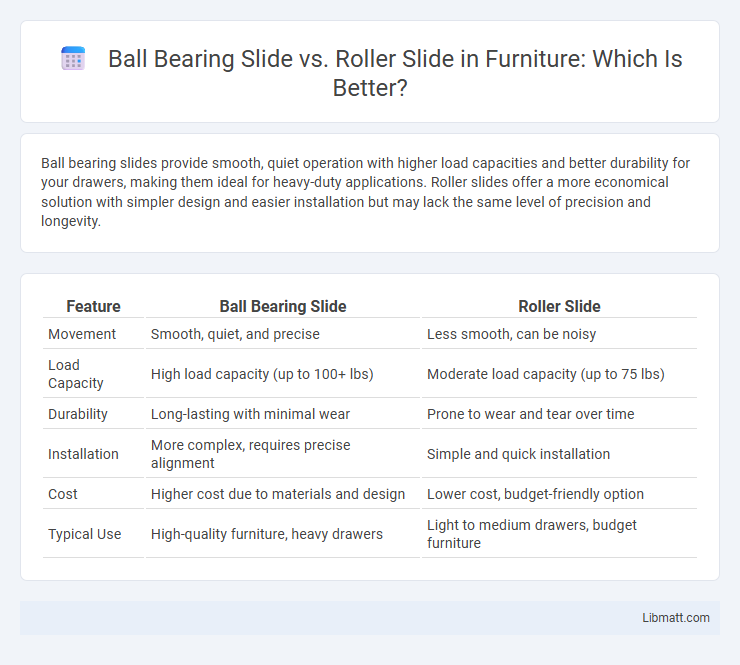

Ball bearing slides provide smooth, quiet operation with higher load capacities and better durability for your drawers, making them ideal for heavy-duty applications. Roller slides offer a more economical solution with simpler design and easier installation but may lack the same level of precision and longevity.

Table of Comparison

| Feature | Ball Bearing Slide | Roller Slide |

|---|---|---|

| Movement | Smooth, quiet, and precise | Less smooth, can be noisy |

| Load Capacity | High load capacity (up to 100+ lbs) | Moderate load capacity (up to 75 lbs) |

| Durability | Long-lasting with minimal wear | Prone to wear and tear over time |

| Installation | More complex, requires precise alignment | Simple and quick installation |

| Cost | Higher cost due to materials and design | Lower cost, budget-friendly option |

| Typical Use | High-quality furniture, heavy drawers | Light to medium drawers, budget furniture |

Introduction to Ball Bearing Slides and Roller Slides

Ball bearing slides utilize steel balls to provide smooth, low-friction linear motion, making them ideal for applications requiring precision and high load capacity. Roller slides employ cylindrical rollers that distribute weight evenly, offering enhanced durability and stability in heavy-duty or industrial environments. Both types are crucial components in drawer systems and mechanical assemblies, with selection depending on load requirements, operating conditions, and desired lifespan.

Key Differences Between Ball Bearing and Roller Slides

Ball bearing slides utilize small steel balls to reduce friction and provide smooth, quiet motion, while roller slides employ cylindrical rollers for higher load capacity and durability. Ball bearing slides typically offer more precise alignment and are ideal for applications requiring smooth, light-to-moderate load movement. Roller slides are better suited for heavy-duty applications with greater weight demands and rougher operational conditions.

Durability and Longevity Comparison

Ball bearing slides offer superior durability and longevity due to their design featuring hardened steel balls that reduce friction and wear, enabling smooth and consistent operation under heavy loads. Roller slides, which use cylindrical rollers, provide good load capacity but generally experience higher friction and faster wear over time, leading to shorter service life in demanding applications. For long-term performance in industrial and high-usage environments, ball bearing slides are typically more reliable and require less frequent maintenance.

Load Capacity: Which Slide Performs Better?

Ball bearing slides generally offer higher load capacity compared to roller slides, making them ideal for heavy-duty applications where durability and strength are crucial. Roller slides tend to support lighter loads and are more suited for smooth, low-friction movement in moderate weight settings. Your choice should consider the specific load requirements to ensure optimal performance and longevity.

Smoothness and Noise During Operation

Ball bearing slides provide exceptional smoothness during operation due to the precision steel balls that reduce friction, resulting in quiet and effortless movement. Roller slides, while sturdy, tend to be noisier and less smooth because the rollers create more surface contact and friction. Choosing ball bearing slides enhances Your equipment's quiet performance and seamless sliding experience.

Installation and Compatibility Considerations

Ball bearing slides require precise alignment and mounting with standard screw holes, ensuring smooth linear motion and compatibility with a wide range of drawer types. Roller slides typically offer easier installation with fewer mounting constraints but may require specific track sizes for optimal performance. Compatibility depends on load capacity and application requirements, making ball bearing slides preferable for heavy-duty use and roller slides suitable for lighter, less demanding environments.

Maintenance Requirements for Each Slide Type

Ball bearing slides require periodic lubrication and occasional cleaning to prevent debris buildup and ensure smooth operation, making them moderately maintenance-intensive. Roller slides generally need less frequent maintenance due to their simpler design, often requiring only occasional cleaning to remove dirt and dust. Both types benefit from regular inspection to detect wear or damage, but ball bearing slides typically have higher maintenance demands due to their intricate mechanism.

Cost Analysis: Ball Bearing vs Roller Slides

Ball bearing slides typically have higher upfront costs due to precision-engineered steel balls and complex manufacturing processes. Roller slides offer a more budget-friendly option with simpler construction using rollers, resulting in lower material and production expenses. Long-term maintenance costs tend to be higher for roller slides as they experience increased friction and wear compared to the smoother operation and durability of ball bearing slides.

Best Use Cases for Ball Bearing and Roller Slides

Ball bearing slides excel in applications requiring smooth, precise movement under heavy loads, making them ideal for full-extension drawers in office furniture, industrial equipment, and computer servers. Roller slides are better suited for lighter loads and budget-friendly solutions, commonly used in kitchen cabinets, toolboxes, and lightweight storage units where moderate extension and less precision are acceptable. Understanding your load requirements and desired slide performance ensures you select the best slide type for your specific project.

Choosing the Right Slide for Your Application

Ball bearing slides offer smooth, quiet operation with higher load capacities, making them ideal for heavy-duty applications requiring precise movement. Roller slides provide cost-effective performance with moderate load capacity and are better suited for lighter loads and less frequent use. Evaluating your specific application needs, such as load weight, movement frequency, and desired durability, will help you choose the right slide for your project.

Ball bearing slide vs roller slide Infographic

libmatt.com

libmatt.com