Kiln dried wood has a lower moisture content and is more stable, making it less prone to warping and ideal for indoor projects that require precise dimensions. Air dried wood retains more natural moisture, making it better suited for outdoor use where gradual adaptation to ambient humidity occurs.

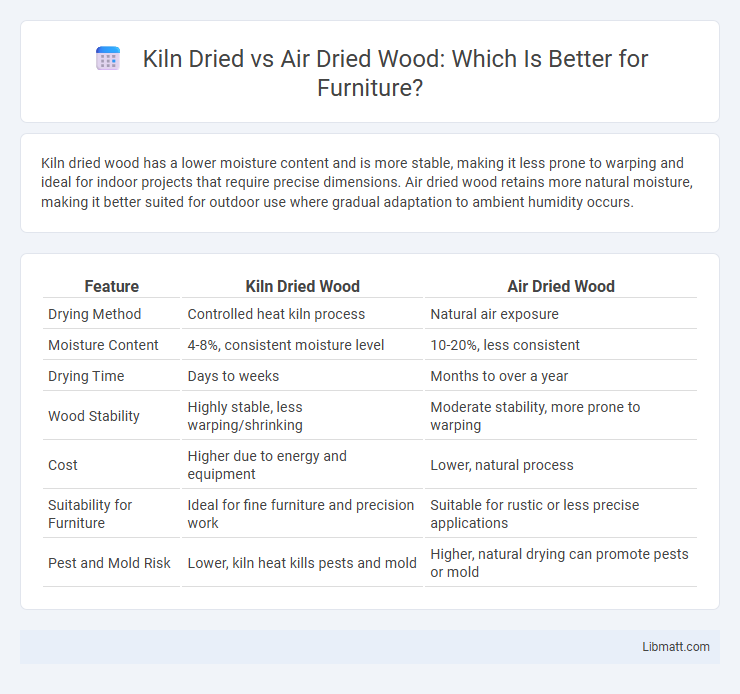

Table of Comparison

| Feature | Kiln Dried Wood | Air Dried Wood |

|---|---|---|

| Drying Method | Controlled heat kiln process | Natural air exposure |

| Moisture Content | 4-8%, consistent moisture level | 10-20%, less consistent |

| Drying Time | Days to weeks | Months to over a year |

| Wood Stability | Highly stable, less warping/shrinking | Moderate stability, more prone to warping |

| Cost | Higher due to energy and equipment | Lower, natural process |

| Suitability for Furniture | Ideal for fine furniture and precision work | Suitable for rustic or less precise applications |

| Pest and Mold Risk | Lower, kiln heat kills pests and mold | Higher, natural drying can promote pests or mold |

Introduction to Kiln Dried and Air Dried Wood

Kiln dried wood is dried in controlled, high-temperature chambers to reduce moisture content rapidly, ensuring consistent quality and stability ideal for construction and furniture making. Air dried wood relies on natural ventilation and ambient conditions to gradually lower moisture content, which can lead to variations in durability and dimensional stability. Comparing moisture content levels, kiln dried wood typically reaches 6-8%, while air dried wood usually retains 12-20%, affecting usability in different applications.

The Drying Processes: Kiln vs Air

Kiln drying involves placing wood in a controlled environment where heat, humidity, and airflow are precisely regulated to reduce moisture content quickly and uniformly, typically achieving a moisture level of 6-8%. Air drying relies on natural ventilation and ambient temperature to evaporate moisture over several months, resulting in variable moisture levels that depend on climate conditions. Your choice between kiln dried wood and air dried wood affects stability and durability, with kiln drying offering faster processing and more consistency for construction and fine woodworking.

Moisture Content Comparison

Kiln dried wood typically has a moisture content of 6-8%, allowing for faster and more controlled drying compared to air dried wood, which usually retains moisture levels between 12-20% depending on environmental conditions. The lower moisture content in kiln dried wood reduces the risk of warping, cracking, and fungal growth, making it more stable and durable for construction and woodworking projects. Air dried wood's higher moisture content requires longer acclimation times and may lead to dimensional changes after installation.

Speed and Efficiency of Drying Methods

Kiln dried wood undergoes a controlled drying process using high temperatures and regulated humidity, reducing moisture content to target levels within days to weeks, significantly faster than air drying, which may take several months to a year depending on climate conditions. The kiln drying method enhances efficiency by minimizing wood defects such as warping, cracking, and fungal growth, making it ideal for commercial woodworking and construction projects requiring consistent quality. In contrast, air dried wood often retains higher moisture variability and requires extensive space and monitoring, limiting its speed and scalability in industrial applications.

Impact on Wood Quality and Stability

Kiln dried wood undergoes controlled temperature and humidity processes that significantly reduce moisture content, enhancing its dimensional stability and resistance to warping or cracking. Air dried wood, while slower to dry and more prone to environmental variability, retains a more natural moisture gradient that can sometimes lead to internal stresses and reduced uniformity. Your choice between kiln dried and air dried wood directly impacts the durability, strength, and long-term performance of woodworking projects.

Cost Differences Between Kiln and Air Drying

Kiln dried wood typically costs more than air dried wood due to the energy and equipment required in the kiln drying process, which accelerates moisture removal. Air drying relies on natural ventilation and sunlight, making it a slower but more cost-effective method for drying lumber. Your choice depends on balancing upfront costs with drying speed and moisture control needs.

Environmental Considerations

Kiln dried wood uses controlled heat and humidity to reduce moisture content quickly, consuming more energy and producing a higher carbon footprint compared to air dried wood, which relies on natural airflow and sunlight, making it a more environmentally friendly option. However, kiln drying reduces pests and fungi, minimizing chemical treatments and extending wood lifespan, which can offset some environmental impacts. Choosing air dried wood supports lower energy consumption and sustainable forestry practices, benefiting Your eco-conscious projects.

Best Uses for Kiln Dried Wood

Kiln dried wood offers superior moisture control, making it ideal for indoor furniture, cabinetry, and flooring where stability and resistance to warping are crucial. Its reduced moisture content ensures faster finishing and painting processes, enhancing durability and appearance. You benefit from kiln dried wood in projects demanding precision and long-lasting quality.

Best Uses for Air Dried Wood

Air dried wood is best suited for indoor furniture, cabinetry, and decorative projects where moderate moisture content enhances stability and workability. Its slower drying process preserves natural wood characteristics, making it ideal for artisanal woodworking and rustic designs. This method reduces the risk of surface cracks and warping, providing durable material for seasoned wood applications.

Choosing the Right Drying Method for Your Project

Kiln dried wood offers consistent moisture content around 6-8%, making it ideal for indoor projects requiring dimensional stability and resistance to warping. Air dried wood, with moisture content typically between 12-20%, is preferred for outdoor applications where natural moisture equilibrium is acceptable. Selecting the right drying method depends on project requirements for moisture control, drying time, and wood stability, influencing longevity and structural integrity.

kiln dried wood vs air dried wood Infographic

libmatt.com

libmatt.com