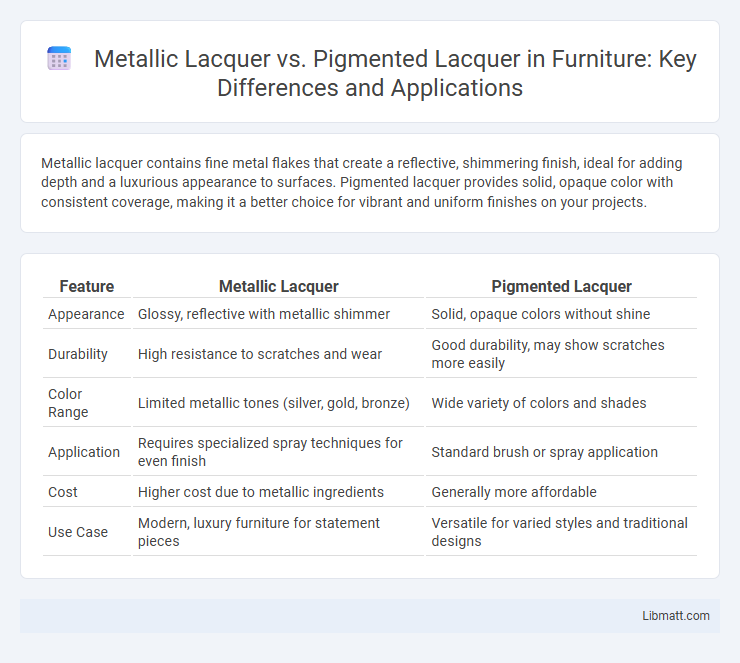

Metallic lacquer contains fine metal flakes that create a reflective, shimmering finish, ideal for adding depth and a luxurious appearance to surfaces. Pigmented lacquer provides solid, opaque color with consistent coverage, making it a better choice for vibrant and uniform finishes on your projects.

Table of Comparison

| Feature | Metallic Lacquer | Pigmented Lacquer |

|---|---|---|

| Appearance | Glossy, reflective with metallic shimmer | Solid, opaque colors without shine |

| Durability | High resistance to scratches and wear | Good durability, may show scratches more easily |

| Color Range | Limited metallic tones (silver, gold, bronze) | Wide variety of colors and shades |

| Application | Requires specialized spray techniques for even finish | Standard brush or spray application |

| Cost | Higher cost due to metallic ingredients | Generally more affordable |

| Use Case | Modern, luxury furniture for statement pieces | Versatile for varied styles and traditional designs |

Understanding Metallic Lacquer: Key Features

Metallic lacquer contains fine metal flakes that create a reflective, shimmering finish, enhancing the depth and dimension of surfaces. This type of lacquer offers superior durability and resistance to UV rays, making it ideal for automotive and decorative applications where a glossy, metallic effect is desired. Your choice of metallic lacquer can significantly impact the visual appeal and longevity of the coated object compared to standard pigmented lacquer.

What Is Pigmented Lacquer?

Pigmented lacquer contains finely ground pigments that provide solid, opaque color and excellent coverage on various surfaces. Unlike metallic lacquer, which reflects light with metal flakes for a shimmering effect, pigmented lacquer delivers a uniform, durable finish that resists fading and wear. Your choice of pigmented lacquer ensures vibrant, consistent coloration ideal for wood, metal, and automotive projects requiring a strong, long-lasting coat.

Composition Differences: Metallic vs Pigmented Lacquer

Metallic lacquer contains fine metal flakes or powders, such as aluminum or bronze, suspended within the binder, which create a reflective, shimmering finish by scattering light. Pigmented lacquer, on the other hand, relies on finely ground inorganic or organic pigments dispersed uniformly throughout the binder to produce solid, opaque color without metallic effects. Understanding these composition differences helps you choose the appropriate lacquer based on the desired visual impact and surface performance for your project.

Application Techniques for Metallic Lacquer

Metallic lacquer requires precise application techniques, such as using multiple thin coats and maintaining a consistent spray distance to achieve a smooth, reflective finish. Proper surface preparation, including thorough cleaning and light sanding, ensures better adhesion and reduces the risk of imperfections. You should also use a high-quality spray gun with adjustable air pressure to control the metallic pigment distribution for an even, vibrant effect.

Applying Pigmented Lacquer: Best Practices

Applying pigmented lacquer requires thorough surface preparation, including sanding and cleaning, to ensure optimal adhesion and uniform coverage. Use a high-quality spray gun or brush to apply thin, even coats, allowing adequate drying time between layers to prevent runs or uneven textures. Maintaining consistent temperature and humidity levels during application enhances the lacquer's durability and finish quality.

Durability and Longevity: Metallic vs Pigmented Finishes

Metallic lacquer offers enhanced durability due to its reflective metal flakes that provide added resistance to scratches and UV damage, extending the finish's longevity. Pigmented lacquer, while vibrant and opaque, may be more prone to fading and surface wear over time compared to metallic finishes. Choosing metallic lacquer can ensure your project maintains its aesthetic appeal and structural integrity longer under various environmental conditions.

Visual Effects: Comparing Finish Aesthetics

Metallic lacquer features tiny metal flakes that create a shimmering, reflective finish, producing dynamic light reflections and a sense of depth not achievable with pigmented lacquer. Pigmented lacquer offers a solid, opaque color with a smooth, uniform surface ideal for consistent coverage and vibrant hues. The choice between metallic and pigmented lacquers significantly influences the visual texture and light interaction of the finished product.

Maintenance and Care for Both Lacquer Types

Metallic lacquer requires careful cleaning to avoid dulling its reflective finish, using non-abrasive, pH-neutral cleaners and soft cloths to maintain its luster. Pigmented lacquer demands regular dusting and gentle polishing to prevent surface scratches and preserve color vibrancy. Both lacquer types benefit from avoiding prolonged exposure to direct sunlight and harsh chemicals to extend durability and aesthetic appeal.

Cost Comparison: Metallic vs Pigmented Lacquer

Metallic lacquer generally costs more than pigmented lacquer due to the specialized metallic flakes and complex manufacturing process required for its reflective finish. Pigmented lacquer offers a more affordable option as it relies on simpler pigments and conventional production techniques. Your choice between the two should consider budget constraints alongside desired aesthetic effects and durability.

Choosing the Right Lacquer for Your Project

Selecting the right lacquer depends on the desired finish and application surface: metallic lacquer offers a reflective, shimmering effect ideal for automotive and decorative projects seeking a modern, eye-catching look. Pigmented lacquer provides a solid, opaque color layer with excellent durability and UV resistance, making it suitable for furniture, cabinetry, and surfaces requiring consistent color coverage. Understanding the environmental exposure and aesthetic needs ensures optimal adhesion, longevity, and visual impact of the lacquered surface.

metallic lacquer vs pigmented lacquer Infographic

libmatt.com

libmatt.com