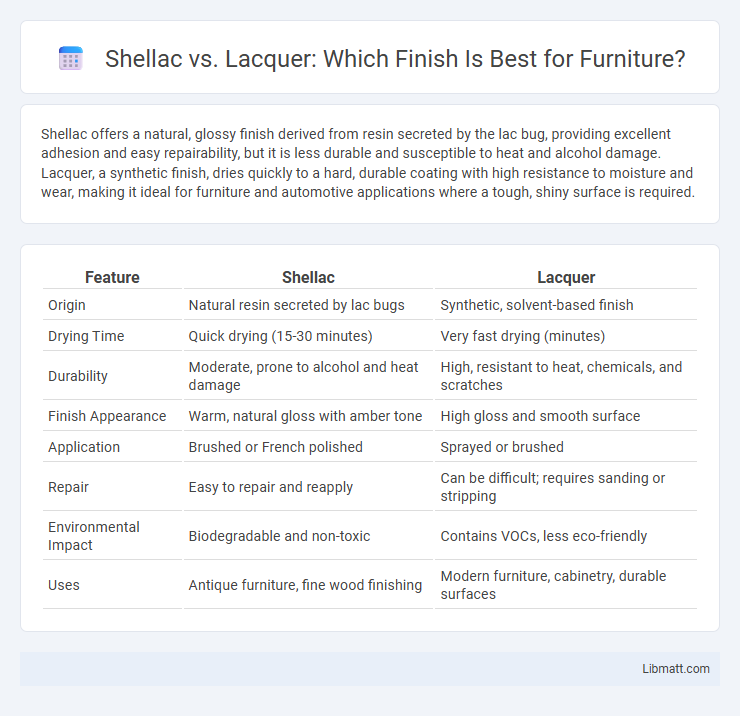

Shellac offers a natural, glossy finish derived from resin secreted by the lac bug, providing excellent adhesion and easy repairability, but it is less durable and susceptible to heat and alcohol damage. Lacquer, a synthetic finish, dries quickly to a hard, durable coating with high resistance to moisture and wear, making it ideal for furniture and automotive applications where a tough, shiny surface is required.

Table of Comparison

| Feature | Shellac | Lacquer |

|---|---|---|

| Origin | Natural resin secreted by lac bugs | Synthetic, solvent-based finish |

| Drying Time | Quick drying (15-30 minutes) | Very fast drying (minutes) |

| Durability | Moderate, prone to alcohol and heat damage | High, resistant to heat, chemicals, and scratches |

| Finish Appearance | Warm, natural gloss with amber tone | High gloss and smooth surface |

| Application | Brushed or French polished | Sprayed or brushed |

| Repair | Easy to repair and reapply | Can be difficult; requires sanding or stripping |

| Environmental Impact | Biodegradable and non-toxic | Contains VOCs, less eco-friendly |

| Uses | Antique furniture, fine wood finishing | Modern furniture, cabinetry, durable surfaces |

Introduction to Shellac and Lacquer

Shellac is a natural resin secreted by the lac bug, dissolved in alcohol to create a fast-drying, glossy finish commonly used in woodworking for its easy application and warm amber tone. Lacquer, typically made from synthetic or cellulose-based compounds, offers a durable, high-gloss surface with excellent resistance to moisture and scratches, favored for its smooth, professional look. Your choice between shellac and lacquer depends on the desired aesthetic, durability requirements, and the type of project you are finishing.

Composition and Ingredients

Shellac is a natural resin secreted by the lac bug, dissolved in alcohol to create a protective finish primarily composed of organic compounds like resins and waxes. Lacquer consists of synthetic polymers dissolved in solvents such as nitrocellulose or acrylic-based chemicals, offering a durable, glossy coating. Your choice between shellac and lacquer depends on the desired finish, environmental impact, and drying time influenced by their distinct chemical compositions.

Application Techniques

Shellac requires a brush or pad for application, often applied in thin, multiple coats that dry quickly to create a smooth, glossy finish. Lacquer typically uses a spray gun for even, fast application, forming a durable and hard layer ideal for furniture and automotive surfaces. Your choice depends on the desired finish and available tools, as shellac offers easier touch-ups while lacquer provides superior protection.

Drying and Curing Times

Shellac dries rapidly, often within 15 to 30 minutes, making it ideal for quick recoating and fast project completion. Lacquer also dries quickly, typically within 15 to 20 minutes, but requires longer curing times ranging from several hours to days to achieve full hardness and durability. The extended curing period of lacquer enhances its resistance to chemicals and physical wear compared to the relatively softer finish of shellac.

Durability and Protection

Shellac offers a natural barrier that resists moisture and provides moderate durability, making it suitable for indoor furniture and decorative items. Lacquer forms a hard, durable finish that withstands scratches, heat, and chemicals better than shellac, ensuring superior long-term protection for high-use surfaces. Choosing lacquer enhances Your furniture's resilience, while shellac provides a softer, more traditional protective coat.

Finish and Appearance

Shellac provides a warm, rich finish with a natural amber hue that enhances wood grain and offers a glossy, smooth surface. Lacquer delivers a durable, high-gloss or satin finish that resists scratches and moisture, ideal for a sleek, modern appearance. Your choice depends on whether you prefer the traditional, organic look of shellac or the resilient, polished sheen of lacquer.

Ease of Maintenance and Repair

Shellac offers easier maintenance and repair because it can be reactivated with alcohol, allowing you to fix minor damages or apply touch-ups effortlessly without stripping the entire finish. Lacquer, while durable, requires more skill and proper solvents for repairs, often involving stripping and reapplication that can be time-consuming. Your choice should consider how frequently you expect to maintain or repair the surface, with shellac providing simpler upkeep for DIY enthusiasts.

Environmental Impact

Shellac is a natural resin derived from lac bugs, making it biodegradable and low in volatile organic compounds (VOCs), which contributes to a reduced environmental impact compared to synthetic finishes. Lacquer typically contains higher levels of VOCs and solvents, leading to greater air pollution and health risks during application. You can minimize ecological harm by choosing shellac for eco-friendly woodworking or furniture refinishing projects.

Common Uses and Best Practices

Shellac is commonly used for fine woodworking, antique restoration, and as a natural finish on furniture due to its warm tone and easy repairability, while lacquer is preferred for modern furniture, cabinetry, and automotive finishes because of its durability and high-gloss appearance. Best practices for shellac application include using dewaxed shellac and applying multiple thin coats with a brush or pad for a smooth, flexible finish; lacquer requires spraying in thin, even layers with proper ventilation to achieve a hard, durable, and fast-drying surface. Both finishes benefit from sanding between coats for enhanced adhesion and optimal appearance.

Choosing Between Shellac and Lacquer

Choosing between shellac and lacquer depends on the desired finish and application context. Shellac offers a warm, natural appearance with quick drying times, making it ideal for fine furniture restoration and antiques. Lacquer provides a durable, glossy finish resistant to scratches and chemicals, best suited for modern cabinetry and automotive finishes, ensuring your project's longevity and aesthetic appeal.

shellac vs lacquer Infographic

libmatt.com

libmatt.com