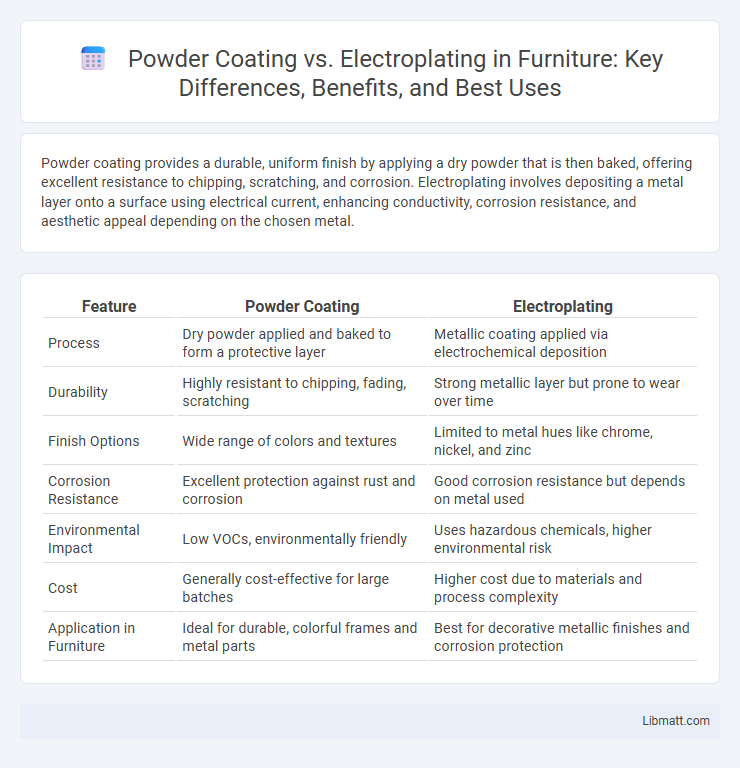

Powder coating provides a durable, uniform finish by applying a dry powder that is then baked, offering excellent resistance to chipping, scratching, and corrosion. Electroplating involves depositing a metal layer onto a surface using electrical current, enhancing conductivity, corrosion resistance, and aesthetic appeal depending on the chosen metal.

Table of Comparison

| Feature | Powder Coating | Electroplating |

|---|---|---|

| Process | Dry powder applied and baked to form a protective layer | Metallic coating applied via electrochemical deposition |

| Durability | Highly resistant to chipping, fading, scratching | Strong metallic layer but prone to wear over time |

| Finish Options | Wide range of colors and textures | Limited to metal hues like chrome, nickel, and zinc |

| Corrosion Resistance | Excellent protection against rust and corrosion | Good corrosion resistance but depends on metal used |

| Environmental Impact | Low VOCs, environmentally friendly | Uses hazardous chemicals, higher environmental risk |

| Cost | Generally cost-effective for large batches | Higher cost due to materials and process complexity |

| Application in Furniture | Ideal for durable, colorful frames and metal parts | Best for decorative metallic finishes and corrosion protection |

Introduction to Powder Coating and Electroplating

Powder coating is a dry finishing process that applies a protective and decorative layer of powdered resin onto metal surfaces through electrostatic attraction, followed by curing at high temperatures for a durable, corrosion-resistant finish. Electroplating involves depositing a thin metal layer onto a substrate using an electric current, enhancing surface properties such as corrosion resistance, conductivity, and aesthetic appeal. Both methods are widely used in manufacturing and automotive industries, with powder coating offering thicker coatings and electroplating providing precise, thin metal layers.

How Powder Coating Works

Powder coating works by applying a dry, electrically charged powder to a grounded metal surface, where it adheres uniformly due to electrostatic attraction. Once coated, the object is heated in an oven, causing the powder to melt, flow, and chemically cross-link into a durable, smooth, and protective finish. This process creates a thicker and more resistant coating compared to traditional liquid paint, offering superior corrosion resistance and enhanced durability.

How Electroplating Works

Electroplating works by using an electric current to deposit a thin layer of metal onto a conductive surface, enhancing corrosion resistance and improving appearance. The process involves immersing the object in an electrolyte solution containing metal ions, which are attracted to the object's surface as the current passes through. This precise metal coating provides durable protection and can be customized to fit your specific material needs.

Key Differences Between Powder Coating and Electroplating

Powder coating uses a dry powder applied electrostatically and cured under heat to create a durable and colorful finish, while electroplating involves depositing a metal layer onto a surface using an electrical current for enhanced corrosion resistance and conductivity. Your choice depends on factors like desired appearance, environmental impact, cost, and the specific application requirements. Powder coating offers a thicker, more uniform coat ideal for corrosion protection, whereas electroplating provides a thinner, metal-based finish with superior conductivity and wear resistance.

Material Compatibility and Surface Preparation

Powder coating offers excellent material compatibility with metals like steel, aluminum, and iron, requiring minimal surface preparation focused mainly on cleaning and degreasing to ensure adhesion. Electroplating suits a wider range of conductive materials, including copper, nickel, and brass, but demands more extensive surface preparation such as polishing and etching to remove contaminants and promote uniform metal deposition. Your choice should consider the substrate type and the level of surface preparation feasible for optimal coating performance.

Durability and Corrosion Resistance Comparison

Powder coating provides a thick, protective layer that resists chipping, scratching, and fading, ensuring long-lasting durability in outdoor and industrial environments. Electroplating offers excellent corrosion resistance by applying a metal coating such as zinc, nickel, or chromium that creates a barrier against oxidation and rust. While powder coating excels in impact resistance, electroplating is superior for applications requiring precise, thin coatings with enhanced chemical resistance.

Environmental Impact and Safety Considerations

Powder coating is an environmentally friendly finishing process that emits minimal volatile organic compounds (VOCs) and produces less hazardous waste compared to electroplating, which often involves toxic chemicals like chromium and cadmium posing risks to both workers and ecosystems. Your choice between these methods should weigh the lower environmental impact and improved safety profile of powder coating against the durable, corrosion-resistant finish offered by electroplating, which requires strict handling protocols to mitigate health hazards. Proper ventilation, protective gear, and waste management are critical safety considerations when opting for electroplating to minimize exposure to harmful substances.

Aesthetic Options and Finish Quality

Powder coating offers a wide range of vibrant colors and textures, providing a durable, uniform, and matte to glossy finish that resists chipping and fading. Electroplating delivers a highly reflective, smooth, and metallic finish, enhancing corrosion resistance with options like chrome, nickel, and gold plating for a premium aesthetic. Both methods ensure high-quality finishes, but powder coating excels in color variety while electroplating stands out with its lustrous, metallic appearance.

Cost Analysis: Powder Coating vs Electroplating

Powder coating generally offers a lower cost per unit compared to electroplating due to reduced material waste and energy consumption during application. Electroplating involves higher expenses from chemical baths and disposal, along with longer process times, which can increase overall production costs. Your choice should consider budget constraints and volume requirements, as powder coating provides a cost-effective solution for large-scale, durable finishes.

Choosing the Right Finishing Method for Your Application

Powder coating offers a durable, corrosion-resistant finish ideal for outdoor applications, while electroplating provides a thinner, conductive layer suited for electronics and decorative purposes. Choosing the right finishing method depends on factors such as desired thickness, environmental exposure, adhesion requirements, and cost efficiency. Evaluating the substrate material and end-use conditions ensures optimal performance and longevity of the coating.

powder coating vs electroplating Infographic

libmatt.com

libmatt.com