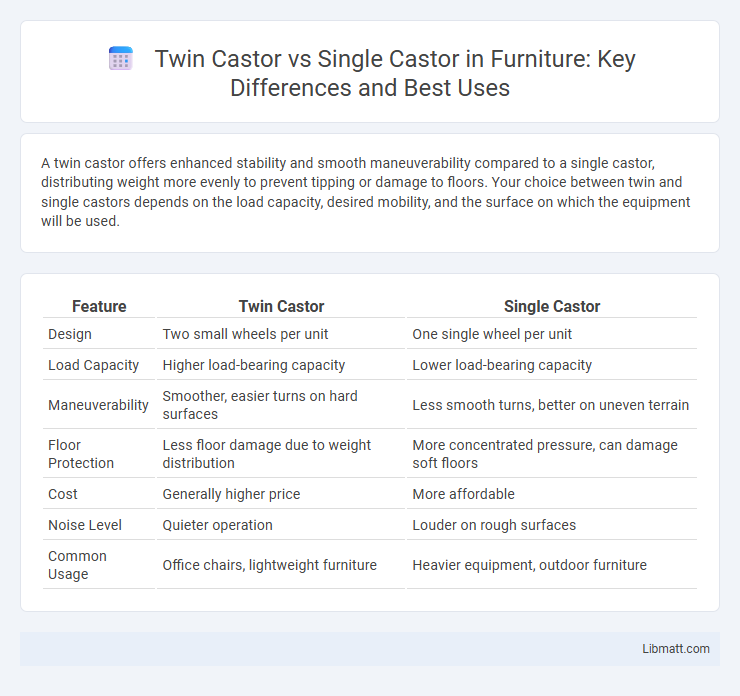

A twin castor offers enhanced stability and smooth maneuverability compared to a single castor, distributing weight more evenly to prevent tipping or damage to floors. Your choice between twin and single castors depends on the load capacity, desired mobility, and the surface on which the equipment will be used.

Table of Comparison

| Feature | Twin Castor | Single Castor |

|---|---|---|

| Design | Two small wheels per unit | One single wheel per unit |

| Load Capacity | Higher load-bearing capacity | Lower load-bearing capacity |

| Maneuverability | Smoother, easier turns on hard surfaces | Less smooth turns, better on uneven terrain |

| Floor Protection | Less floor damage due to weight distribution | More concentrated pressure, can damage soft floors |

| Cost | Generally higher price | More affordable |

| Noise Level | Quieter operation | Louder on rough surfaces |

| Common Usage | Office chairs, lightweight furniture | Heavier equipment, outdoor furniture |

Introduction to Castors: Twin vs Single

Single castors feature one wheel per assembly, offering simplicity and cost-effectiveness ideal for lighter loads and smoother surfaces. Twin castors incorporate two parallel wheels, enhancing load distribution, stability, and maneuverability on uneven or heavy-duty applications. Choosing between twin and single castors depends on factors like weight capacity, floor conditions, and required mobility for industrial or commercial equipment.

Design Differences: Twin Castor vs Single Castor

Twin castors feature two small wheels mounted side by side, offering enhanced stability, smoother rolling, and better load distribution compared to single castors, which consist of only one wheel. The dual-wheel design reduces floor damage and improves maneuverability on uneven surfaces, making twin castors ideal for heavier loads and frequent movement. Your choice between twin and single castors should consider the balance between load capacity, floor protection, and ease of mobility required for your application.

Load Capacity Comparison

Twin castors offer a higher load capacity than single castors by evenly distributing the weight across two wheels, reducing stress on each wheel and enhancing stability. Single castors typically handle lower weight limits, making them suitable for lighter applications where maneuverability is prioritized over heavy load support. For example, twin castors can support loads up to 300 kg per unit, whereas single castors usually max out around 150 kg.

Maneuverability and Mobility

Twin castors enhance maneuverability by allowing smoother, more precise turns and better weight distribution compared to single castors. Your equipment will experience increased mobility over uneven surfaces, as twin castors absorb shocks more effectively and reduce vibration. This results in easier navigation in tight spaces and improved overall stability during movement.

Floor Protection and Wear

Twin castors distribute weight more evenly across a larger surface area, significantly reducing floor damage compared to single castors with concentrated pressure points. The dual wheels in twin castors allow smoother movement and minimize wear on both the castor and flooring, extending the lifespan of both. Single castors, while compact, tend to cause more indentation and scuff marks on softer floor materials due to higher localized stress and faster wheel wear.

Application Suitability for Twin and Single Castors

Twin castors offer enhanced stability and load distribution, making them ideal for applications requiring smooth maneuverability on uneven surfaces, such as hospital beds and heavy equipment trolleys. Single castors excel in tasks demanding tight turning radii and precise movements, often used in office chairs and small carts. Selecting between twin and single castors depends on load capacity, floor type, and directional control requirements in specific industrial or commercial settings.

Installation and Maintenance Considerations

Twin castors require more precise installation due to their dual-wheel alignment but offer better stability and load distribution, reducing wear over time. Single castors are simpler to install and maintain but may experience quicker wear and increased swiveling resistance under heavy loads. Choosing twin castors can enhance your equipment's longevity by minimizing maintenance frequency and providing smoother maneuverability.

Cost Analysis: Twin vs Single Castors

Twin castors generally cost more upfront than single castors due to their dual wheel design, which provides better weight distribution and smoother movement. Your investment in twin castors can reduce maintenance expenses over time by minimizing floor damage and improving load stability. While single castors offer a lower initial price, they may lead to higher long-term costs related to wear and replacement.

Pros and Cons of Each Castor Type

Twin castors offer enhanced stability and weight distribution, reducing floor damage and improving mobility on uneven surfaces, but they tend to be bulkier and more expensive than single castors. Single castors provide greater maneuverability and a smaller footprint, ideal for tight spaces, yet they may compromise load stability and increase wear on floors under heavy loads. Choosing between twin and single castors depends on factors like load capacity, surface type, and required maneuverability for specific applications.

Choosing the Right Castor for Your Needs

Twin castors provide enhanced stability and smoother movement on uneven surfaces compared to single castors, making them ideal for heavy loads or equipment requiring increased balance. Single castors offer greater maneuverability and are suitable for lighter loads or confined spaces where tight turning is essential. Selecting the right castor depends on load capacity, floor conditions, and required mobility, ensuring optimal performance and durability for your specific application.

Twin castor vs single castor Infographic

libmatt.com

libmatt.com