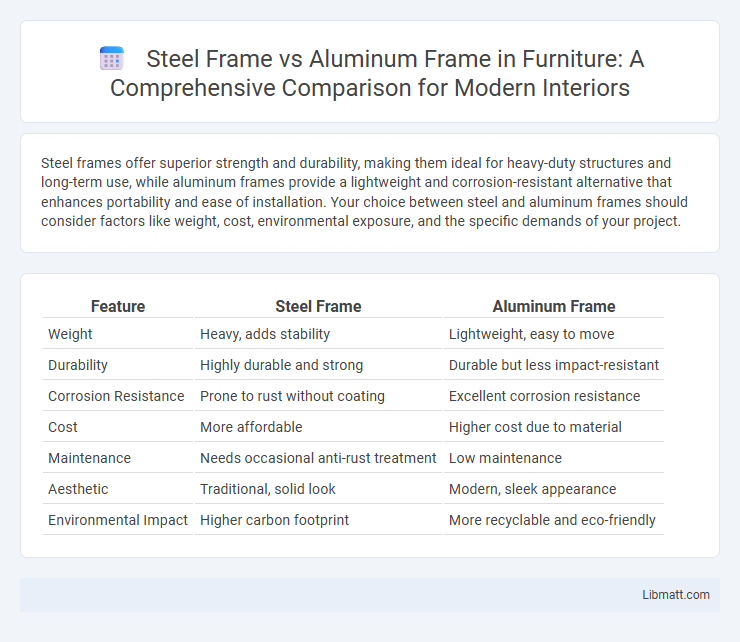

Steel frames offer superior strength and durability, making them ideal for heavy-duty structures and long-term use, while aluminum frames provide a lightweight and corrosion-resistant alternative that enhances portability and ease of installation. Your choice between steel and aluminum frames should consider factors like weight, cost, environmental exposure, and the specific demands of your project.

Table of Comparison

| Feature | Steel Frame | Aluminum Frame |

|---|---|---|

| Weight | Heavy, adds stability | Lightweight, easy to move |

| Durability | Highly durable and strong | Durable but less impact-resistant |

| Corrosion Resistance | Prone to rust without coating | Excellent corrosion resistance |

| Cost | More affordable | Higher cost due to material |

| Maintenance | Needs occasional anti-rust treatment | Low maintenance |

| Aesthetic | Traditional, solid look | Modern, sleek appearance |

| Environmental Impact | Higher carbon footprint | More recyclable and eco-friendly |

Introduction to Frame Materials

Steel frames offer exceptional strength and durability, making them ideal for heavy-duty applications and structures requiring high load-bearing capacity. Aluminum frames are lightweight and resistant to corrosion, providing excellent performance in environments prone to moisture and reducing overall structural weight. Your choice between steel and aluminum frames should consider factors such as weight requirements, environmental exposure, and long-term maintenance needs.

Overview of Steel Frames

Steel frames offer exceptional strength and durability, making them ideal for construction projects requiring high load-bearing capacity and resistance to environmental stressors. Their corrosion resistance is enhanced with protective coatings, ensuring long-term structural integrity in various climates. Choosing a steel frame for Your project provides superior rigidity and longevity compared to aluminum, especially in heavy-duty applications.

Overview of Aluminum Frames

Aluminum frames are lightweight, corrosion-resistant, and require minimal maintenance, making them ideal for various applications including bicycles, windows, and structural components. Their strength-to-weight ratio provides durability without adding excessive weight, enhancing performance and ease of handling. You benefit from aluminum frames' ability to withstand harsh environments while maintaining structural integrity over time.

Strength and Durability Comparison

Steel frames offer superior strength and high load-bearing capacity, making them ideal for heavy-duty construction projects requiring long-term durability. Aluminum frames are lightweight with excellent corrosion resistance but generally less strength compared to steel, making them suitable for applications where weight reduction is a priority. Your choice should consider the balance between steel's robustness and aluminum's resistance to environmental factors for optimal structural performance.

Weight Differences

Steel frames are significantly heavier than aluminum frames due to the higher density of steel, impacting transport and handling ease. Aluminum frames offer a lighter alternative, enhancing maneuverability and reducing fatigue during extended use. Your choice of frame material will influence overall weight, affecting both performance and comfort.

Cost Analysis

Steel frames generally offer a lower initial cost compared to aluminum frames, making them a cost-effective choice for budget-conscious projects. Aluminum frames, though more expensive upfront, provide long-term savings due to their corrosion resistance and lower maintenance requirements. In construction and manufacturing, the decision between steel and aluminum frames hinges on balancing initial expenses with durability and lifecycle costs.

Corrosion Resistance

Aluminum frames offer superior corrosion resistance compared to steel frames due to aluminum's natural oxide layer that protects the metal from rust and deterioration. Steel frames require protective coatings such as galvanization or paint to prevent corrosion, especially in humid or coastal environments. Choosing aluminum significantly reduces maintenance efforts and extends the lifespan of structures exposed to moisture and varying weather conditions.

Ease of Maintenance

Steel frames require minimal upkeep due to their durability and resistance to wear, often needing only occasional repainting to prevent rust. Aluminum frames boast superior corrosion resistance, making them low-maintenance and ideal for humid or coastal environments. Both materials offer long-lasting performance, but aluminum demands less frequent maintenance compared to steel.

Application Suitability

Steel frames offer superior strength and durability, making them ideal for heavy-duty construction, industrial buildings, and high-rise structures that require robust support and resistance to extreme conditions. Aluminum frames excel in applications requiring lightweight, corrosion-resistant materials, such as residential windows, doors, and architectural facades where ease of installation and maintenance are critical. The choice between steel and aluminum frames depends largely on structural demands, environmental exposure, and cost considerations, with steel favored for load-bearing frameworks and aluminum preferred for aesthetic, lightweight solutions.

Final Verdict: Steel or Aluminum?

Steel frames offer exceptional durability, impact resistance, and repairability, making them ideal for heavy-duty applications and long-term use, while aluminum frames excel in lightweight construction and corrosion resistance, perfect for those prioritizing ease of handling and travel. Your choice depends on whether you value strength and longevity over weight savings and rust resistance. For rugged, long-lasting performance, steel is preferred; for a lighter, rust-proof option, aluminum is the optimal frame material.

steel frame vs aluminum frame Infographic

libmatt.com

libmatt.com