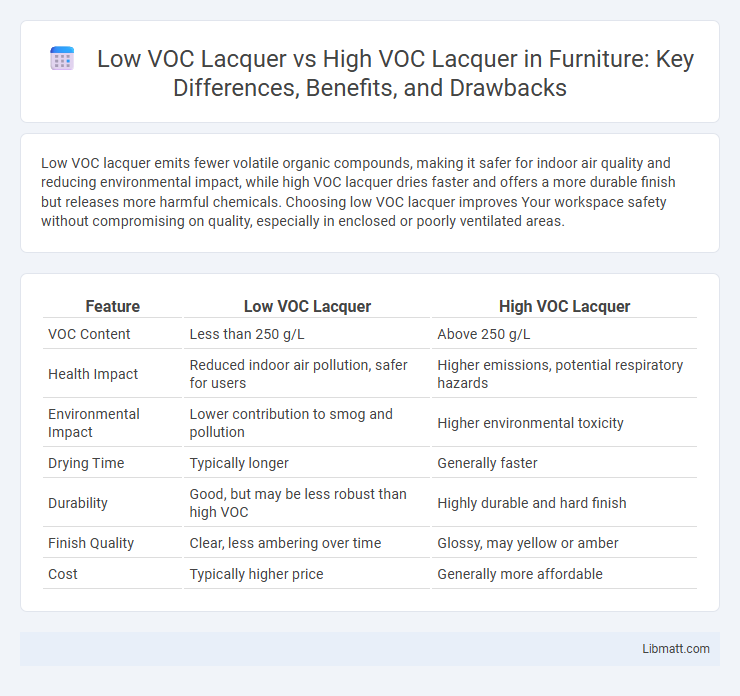

Low VOC lacquer emits fewer volatile organic compounds, making it safer for indoor air quality and reducing environmental impact, while high VOC lacquer dries faster and offers a more durable finish but releases more harmful chemicals. Choosing low VOC lacquer improves Your workspace safety without compromising on quality, especially in enclosed or poorly ventilated areas.

Table of Comparison

| Feature | Low VOC Lacquer | High VOC Lacquer |

|---|---|---|

| VOC Content | Less than 250 g/L | Above 250 g/L |

| Health Impact | Reduced indoor air pollution, safer for users | Higher emissions, potential respiratory hazards |

| Environmental Impact | Lower contribution to smog and pollution | Higher environmental toxicity |

| Drying Time | Typically longer | Generally faster |

| Durability | Good, but may be less robust than high VOC | Highly durable and hard finish |

| Finish Quality | Clear, less ambering over time | Glossy, may yellow or amber |

| Cost | Typically higher price | Generally more affordable |

Introduction to VOCs in Lacquers

Volatile Organic Compounds (VOCs) in lacquers refer to chemicals that evaporate into the air during drying, impacting indoor air quality and environmental safety. Low VOC lacquers contain fewer harmful emissions, making them ideal for improving air quality and complying with stringent environmental regulations. Choosing Your lacquer with lower VOC content reduces health risks and contributes to a safer, more sustainable environment.

What is Low VOC Lacquer?

Low VOC lacquer contains fewer volatile organic compounds, reducing harmful emissions and improving indoor air quality compared to high VOC lacquer. This type of lacquer is designed to provide a durable finish while minimizing environmental impact and health risks associated with toxic fumes. Choosing low VOC lacquer helps protect Your health and supports eco-friendly practices in painting and wood finishing.

What is High VOC Lacquer?

High VOC lacquer contains a higher concentration of volatile organic compounds, which are chemicals that evaporate quickly and contribute to air pollution and smog formation. This type of lacquer offers faster drying times and a harder finish but poses greater health risks and environmental impact due to increased emissions. Choosing low VOC lacquer reduces indoor air toxins and complies with stricter environmental regulations while maintaining a safer finishing option for wood and metal surfaces.

Health Impacts: Low vs High VOC Lacquer

Low VOC lacquer significantly reduces exposure to harmful volatile organic compounds, minimizing respiratory irritation, headaches, and long-term health risks such as liver or kidney damage. In contrast, high VOC lacquer emits stronger toxic fumes that can exacerbate indoor air pollution, posing greater hazards particularly for sensitive individuals like children and those with asthma. Choosing low VOC lacquer protects your health by lowering VOC emissions, making it a safer option for both residential and commercial environments.

Environmental Considerations

Low VOC lacquer significantly reduces the emission of harmful volatile organic compounds, contributing to improved indoor air quality and decreased environmental pollution. High VOC lacquer releases substantial amounts of toxic chemicals that accelerate smog formation and pose health risks to both workers and occupants. Choosing low VOC lacquer supports regulatory compliance with environmental standards and promotes sustainable practices in woodworking and finishing industries.

Performance and Durability Comparison

Low VOC lacquer offers superior flexibility and environmental benefits while maintaining excellent adhesion and resistance to yellowing, making it ideal for indoor applications where air quality is a priority. High VOC lacquer generally provides a harder, more durable finish with faster drying times, which is beneficial for heavy-use surfaces and outdoor environments. Your choice depends on balancing performance needs with regulatory requirements and health considerations.

Application Process Differences

Low VOC lacquer requires specialized application techniques such as multiple thin coats and longer drying times to ensure proper adhesion and finish quality, minimizing VOC emissions. High VOC lacquer allows faster drying and fewer coats due to its higher solvent content, making the application process quicker but producing stronger odors and more environmental impact. Equipment adjustments, like HVLP spray guns, are often necessary for low VOC lacquers to optimize atomization and reduce overspray.

Cost Analysis: Low VOC vs High VOC

Low VOC lacquer typically costs more upfront due to its eco-friendly formulation and stricter manufacturing standards, while high VOC lacquer offers a lower initial price but may incur higher expenses over time related to health risks and environmental regulations. Your choice between low VOC and high VOC lacquer should consider potential savings from reduced ventilation, waste disposal, and compliance costs associated with low VOC products. Investing in low VOC lacquer often delivers better long-term economic benefits despite the higher initial purchase price.

Regulatory Standards and Compliance

Low VOC lacquer complies with stricter regulatory standards set by agencies like the EPA and CARB, ensuring reduced emissions of harmful volatile organic compounds. High VOC lacquer often exceeds these limits, posing greater environmental and health risks, making it less favorable in regions with stringent compliance requirements. Choosing low VOC lacquer supports Your adherence to environmental regulations and promotes safer indoor air quality.

Choosing the Right Lacquer for Your Project

Low VOC lacquer offers environmentally friendly benefits with reduced harmful emissions, making it ideal for indoor projects requiring better air quality and safety. High VOC lacquer provides a more durable and faster-drying finish, suitable for exterior applications or heavy-use surfaces where toughness is a priority. Selecting the right lacquer depends on balancing performance needs with environmental impact and regulatory guidelines.

Low VOC lacquer vs high VOC lacquer Infographic

libmatt.com

libmatt.com