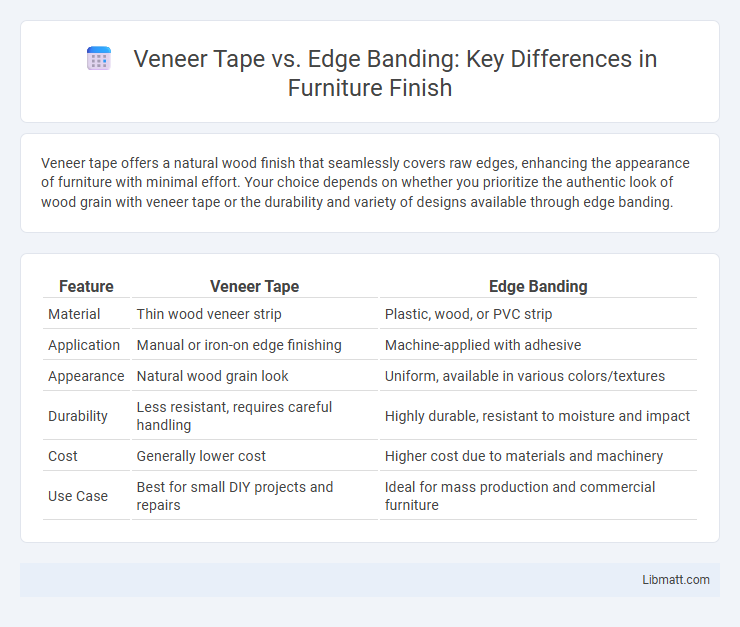

Veneer tape offers a natural wood finish that seamlessly covers raw edges, enhancing the appearance of furniture with minimal effort. Your choice depends on whether you prioritize the authentic look of wood grain with veneer tape or the durability and variety of designs available through edge banding.

Table of Comparison

| Feature | Veneer Tape | Edge Banding |

|---|---|---|

| Material | Thin wood veneer strip | Plastic, wood, or PVC strip |

| Application | Manual or iron-on edge finishing | Machine-applied with adhesive |

| Appearance | Natural wood grain look | Uniform, available in various colors/textures |

| Durability | Less resistant, requires careful handling | Highly durable, resistant to moisture and impact |

| Cost | Generally lower cost | Higher cost due to materials and machinery |

| Use Case | Best for small DIY projects and repairs | Ideal for mass production and commercial furniture |

Introduction to Veneer Tape and Edge Banding

Veneer tape is a thin strip of real wood used to cover raw plywood edges, providing a seamless and natural wood finish. Edge banding is a durable material, typically made from PVC, ABS, or wood veneer, applied to the exposed edges of engineered wood panels for protection and aesthetic enhancement. Both veneer tape and edge banding serve to improve the appearance and durability of furniture and cabinetry edges, with veneer tape offering a more authentic wood look and edge banding providing greater versatility and resilience.

What is Veneer Tape?

Veneer tape is a thin, flexible strip of wood veneer used to cover the exposed edges of plywood, particleboard, or MDF, providing a natural wood appearance. It is typically made from real wood veneers that are backed with adhesive for easy application using an iron or edge bander. Unlike edge banding, which often consists of plastic or composite materials, veneer tape offers a seamless and authentic wood finish.

What is Edge Banding?

Edge banding is a thin strip of material, such as wood veneer, plastic, or PVC, applied to the exposed edges of plywood, particleboard, or MDF to create a finished look and protect the substrate from moisture and damage. Unlike veneer tape, which is typically fabric-backed and iron-on, edge banding is often glued on using hot-melt adhesive or pre-applied adhesive, providing a durable and seamless edge finish. Your choice between veneer tape and edge banding depends on the desired durability, aesthetic, and ease of application for your woodworking project.

Key Differences Between Veneer Tape and Edge Banding

Veneer tape consists of thin slices of natural wood, offering a realistic wood grain finish ideal for repairing or covering minor edges and seams. Edge banding is a broader material selection including PVC, ABS, wood veneer, or melamine, designed to cover raw panel edges, providing durability and aesthetic uniformity. Veneer tape emphasizes natural wood textures with easy application on small repairs, while edge banding ensures protection and a polished look for furniture and cabinetry edges.

Material Composition and Options

Veneer tape is made from thin slices of natural wood veneer, providing an authentic wood grain appearance, typically available in various wood species like oak, maple, cherry, and walnut. Edge banding is crafted from synthetic materials such as PVC, ABS, melamine, or wood veneer, offering a broader range of colors and finishes to match or contrast with furniture surfaces. The choice between veneer tape and edge banding depends on the desired aesthetic, durability, and budget, with veneer tape favored for natural wood looks and edge banding valued for versatility and moisture resistance.

Application Techniques and Tools

Veneer tape is primarily applied using heat-activated adhesives and hot irons, allowing it to seamlessly blend into wood surfaces with minimal preparation, making it ideal for repairing small veneer damages. Edge banding requires more specialized tools such as edge banding machines or iron-on adhesives combined with trimmers and scrapers for precise application on furniture edges, ensuring durability and a smooth finish. Both techniques demand skillful handling, but veneer tape offers a quicker, temporary fix, while edge banding provides a longer-lasting and more professional appearance.

Durability and Longevity Comparison

Veneer tape offers superior durability due to its seamless adhesion and ability to resist moisture and heat, making it ideal for long-lasting furniture edges. Edge banding, while providing a cost-effective finish, tends to be less durable over time as it may peel or chip under heavy wear or exposure to humidity. For projects requiring extended longevity and robust protection, veneer tape is the preferred choice over traditional edge banding.

Aesthetics and Finish Quality

Veneer tape offers a more natural and seamless look by matching the wood grain and texture closely, resulting in superior aesthetics compared to edge banding. The finish quality of veneer tape is smoother, with less visible seams and a more authentic wood appearance, enhancing overall furniture elegance. Edge banding, while easier to apply, often appears thicker and less refined, which can detract from the polished finish of high-end cabinetry or furniture.

Cost Considerations

Veneer tape generally offers a more affordable option compared to edge banding, especially for small projects or repairs, as it requires less specialized equipment and can be applied with simple tools like an iron. Edge banding, while potentially more expensive upfront due to the need for machinery and adhesive, provides a more durable and professional finish suitable for large-scale or commercial woodworking. Your choice should consider the long-term cost-effectiveness, balancing initial expenses with the desired durability and aesthetics.

Choosing the Right Option for Your Project

Veneer tape offers authentic wood grain and texture, making it ideal for high-quality furniture repairs or custom woodworking projects requiring a natural finish. Edge banding, typically made from PVC, ABS, or melamine, provides a durable and cost-effective solution for protecting and enhancing the edges of plywood, MDF, or particleboard surfaces. Selecting between veneer tape and edge banding depends on project demands for aesthetic authenticity, durability, and budget constraints.

Veneer tape vs edge banding Infographic

libmatt.com

libmatt.com