Bent glass is produced by heating flat glass until it softens and then shaping it into a desired angle or bend, typically used for architectural elements like windows and doors, while curved glass undergoes a more precise molding process to achieve smooth, continuous curves ideal for automotive windshields or modern facades. Your choice between bent and curved glass depends on the specific design requirements and the level of curvature needed for your project.

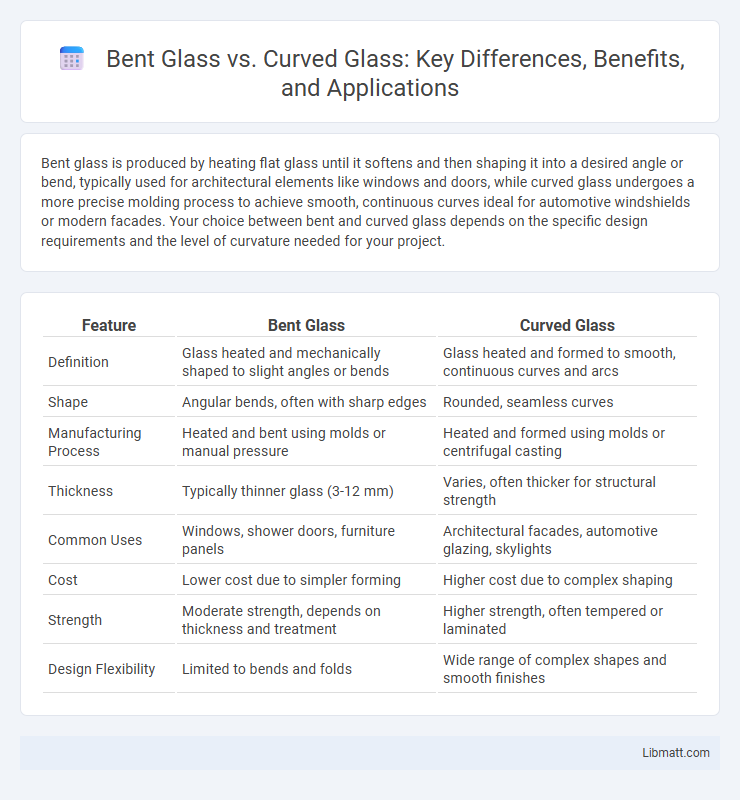

Table of Comparison

| Feature | Bent Glass | Curved Glass |

|---|---|---|

| Definition | Glass heated and mechanically shaped to slight angles or bends | Glass heated and formed to smooth, continuous curves and arcs |

| Shape | Angular bends, often with sharp edges | Rounded, seamless curves |

| Manufacturing Process | Heated and bent using molds or manual pressure | Heated and formed using molds or centrifugal casting |

| Thickness | Typically thinner glass (3-12 mm) | Varies, often thicker for structural strength |

| Common Uses | Windows, shower doors, furniture panels | Architectural facades, automotive glazing, skylights |

| Cost | Lower cost due to simpler forming | Higher cost due to complex shaping |

| Strength | Moderate strength, depends on thickness and treatment | Higher strength, often tempered or laminated |

| Design Flexibility | Limited to bends and folds | Wide range of complex shapes and smooth finishes |

Introduction to Bent and Curved Glass

Bent glass is created by heating flat glass until it softens and then shaping it into a desired angle or contour, often used for architectural elements like windows and doors. Curved glass involves a more complex process where the glass is molded into smooth, continuous curves, making it ideal for applications requiring aerodynamic or aesthetic enhancements such as automotive windshields and modern building facades. Both types utilize tempering and annealing methods to enhance strength and durability, with curved glass generally offering greater versatility in design complexity.

Definition: Bent Glass vs Curved Glass

Bent glass refers to flat glass that has been heated and manually shaped to create slight angles or bends, while curved glass is formed into smooth, continuous arcs or complex shapes through advanced heating and molding techniques. Bent glass typically exhibits sharper bends and retains flat sections between bends, whereas curved glass presents a seamless, uniform curvature ideal for architectural applications. Both types enhance design flexibility but differ primarily in the degree and smoothness of the shaped contours.

Manufacturing Processes Compared

Bent glass is produced by heating flat glass until it softens, then bending it along a specific axis using molds or forms, allowing for precise angles and uniform curves primarily in one direction. Curved glass involves a more complex process--often using cold bending or heat bending--but typically requires shaping glass into compound curves, involving multidimensional curvature achieved through advanced thermoforming or laminating techniques. The manufacturing of curved glass demands higher precision and control in temperature and mold design to maintain optical clarity and structural integrity over variable, double-curved surfaces.

Key Differences in Physical Properties

Bent glass is created by heating flat glass until it softens and then shaping it using molds, resulting in a fixed, uniform curvature with consistent thickness. Curved glass, on the other hand, often involves complex fabrication techniques like cold bending or lamination, allowing for more intricate shapes but sometimes exhibiting slight variations in thickness and tension. Understanding these physical differences ensures your project uses the most suitable glass type for strength, flexibility, and aesthetic requirements.

Applications in Architecture and Design

Bent glass is typically used for subtle bends in windows, canopies, and balustrades, offering smooth, continuous curves that enhance natural light flow and aesthetics. Curved glass allows for more pronounced shapes such as facades, domes, and skylights, providing structural versatility and dramatic visual impact in modern architectural designs. Your choice between bent and curved glass affects the design complexity, installation process, and overall building performance.

Strength and Durability Analysis

Bent glass undergoes heating and controlled cooling to achieve a slight curvature, enhancing its strength by redistributing internal stresses, making it more resistant to impact and thermal stress compared to flat glass. Curved glass, often produced through advanced molding or lamination techniques, offers superior structural integrity and durability due to its uniform curvature and thickness, which evenly disperses applied forces. Choosing between bent and curved glass for your project depends on the specific strength requirements and environmental conditions, with curved glass typically providing higher durability in demanding applications.

Aesthetic and Visual Appeal

Bent glass offers subtle, elegant curves that enhance architectural designs with smooth, gentle contours, creating a modern and minimalist aesthetic. Curved glass provides more dramatic, complex shapes and deeper bends, allowing for striking visual statements and dynamic reflections that elevate building facades and interior spaces. Both types improve natural light diffusion, but curved glass often delivers greater depth and fluidity in visual appeal due to its pronounced curvature.

Cost Comparison: Bent Glass vs Curved Glass

Bent glass typically costs less than curved glass due to its simpler manufacturing process, which involves heating flat glass and bending it to shape without extensive mold use. Curved glass requires custom molds and precise forming techniques, driving up production expenses and lead times. For projects with tight budgets, bent glass offers a more affordable solution while still providing aesthetic appeal, whereas curved glass suits designs demanding complex, smooth curvature.

Customization and Design Flexibility

Bent glass offers limited customization as it involves heating flat glass to a fixed radius, resulting in uniform curves ideal for standard designs. Curved glass provides extensive design flexibility by allowing complex shapes and varying radii, enabling architects and designers to realize unique, bespoke projects. Your choice depends on the level of customization needed for the architectural vision and functional requirements.

Choosing the Right Glass for Your Project

Bent glass offers precise angular bends and is ideal for projects requiring sharp, defined folds, while curved glass provides smooth, continuous curves suitable for more organic, flowing designs. Bent glass typically involves heating and cooling processes to achieve specific angles, making it cost-effective for structural elements like partitions and cabinetry. Curved glass requires advanced shaping and tempering techniques, offering enhanced aesthetics and strength for architectural facades and high-end interior applications.

bent glass vs curved glass Infographic

libmatt.com

libmatt.com